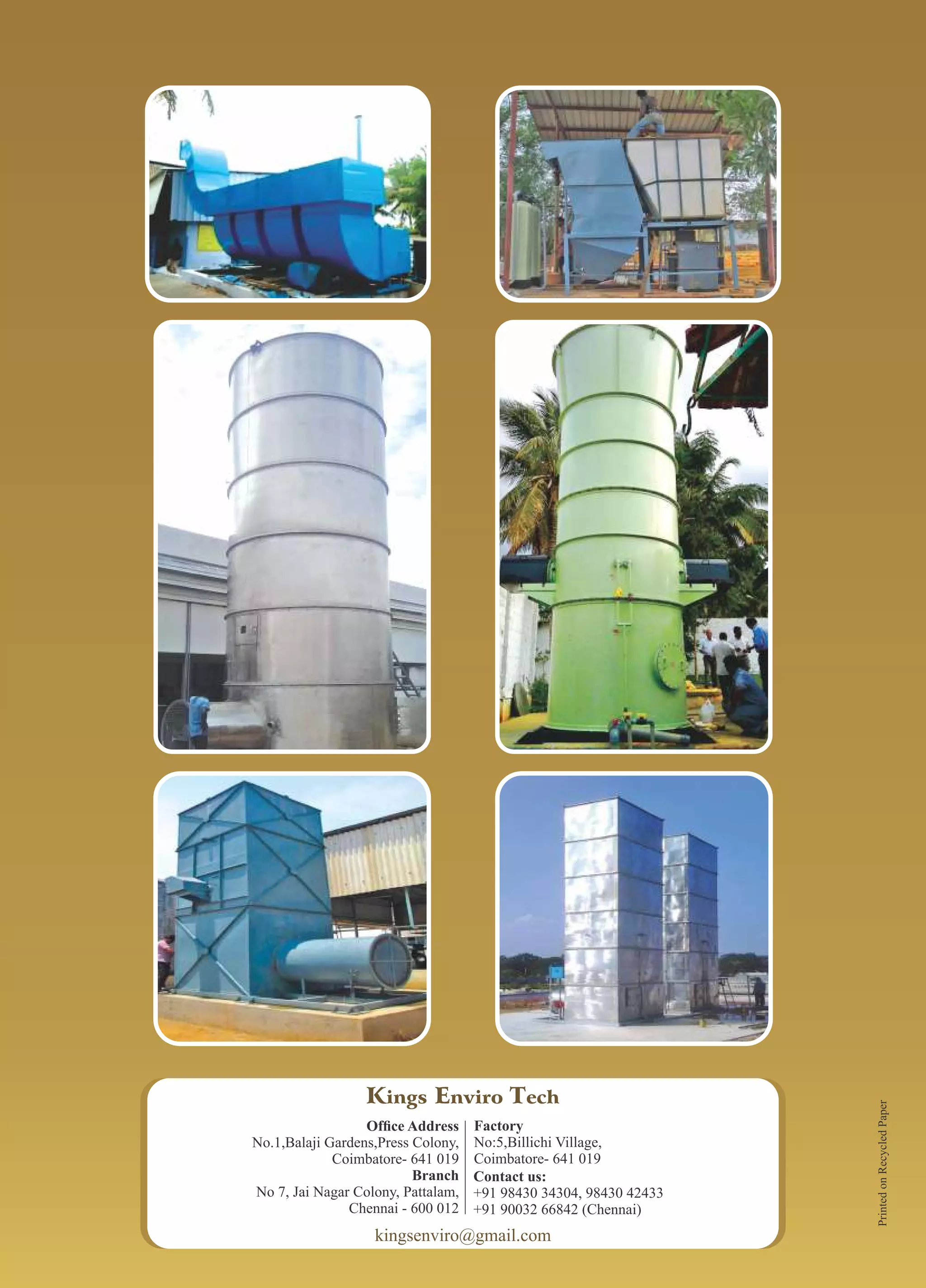

Kings Enviro Tech is a renowned manufacturer and supplier of pollution control equipment in India established in 1998. They offer customized equipment that is efficiently and effectively designed to meet clients' specifications. Their products are widely used across industries and are handled by a skilled team to ensure projects are completed on time. Kings focuses on innovation through research and development to adapt to changing market needs. They provide low cost evaporators, effluent treatment plants, biogas plants, and more to treat industrial wastewater for various applications.