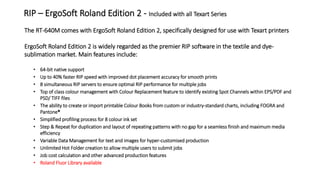

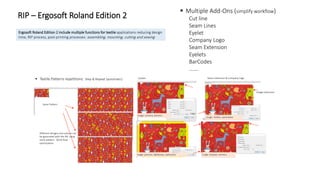

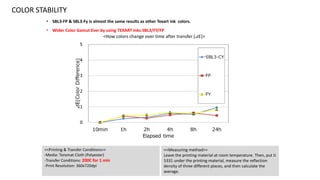

The document discusses the new RT-640M machine and its included ErgoSoft Roland Edition 2 RIP software. The RIP software provides features like improved color management, step and repeat patterns, variable data, and job cost calculation. It also supports printing with new fluorescent pink and yellow inks. The document addresses several common questions about using the machine, including its compatibility with different fabrics, washing durability, and processes for decorating cut fabric pieces.