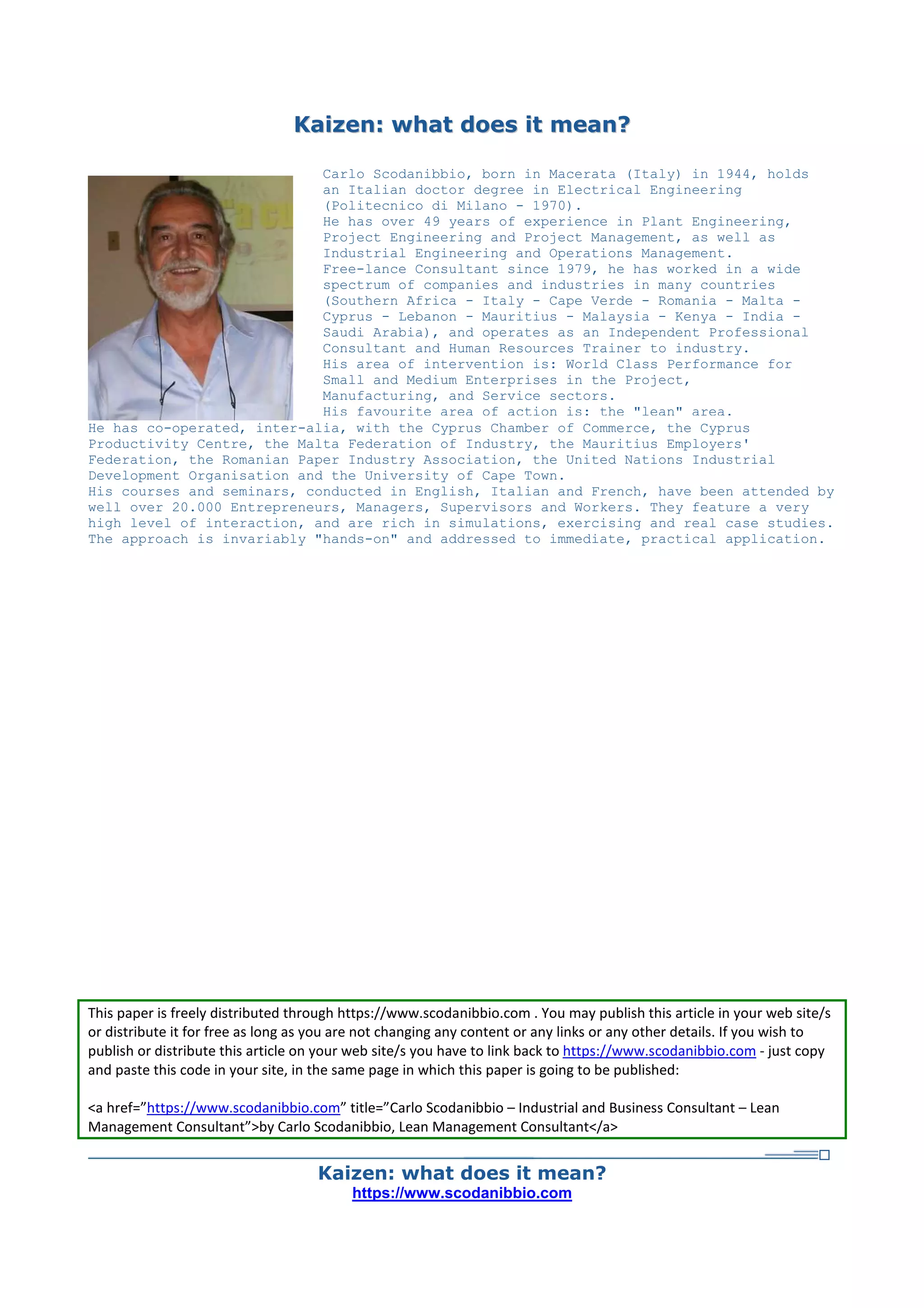

The document discusses the concept of 'kaizen', a Japanese term meaning 'continuous improvement', and its application to home improvement and industrial processes. It contrasts kaizen with 'kairyo', a larger-scale improvement approach, highlighting that kaizen focuses on human creativity and incremental changes rather than financial expenditure. The author emphasizes the importance of teamwork, a shared vision, and personal involvement in successfully implementing kaizen principles in both home and industrial settings.