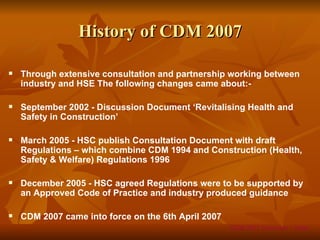

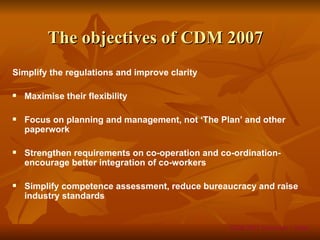

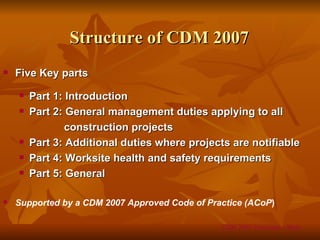

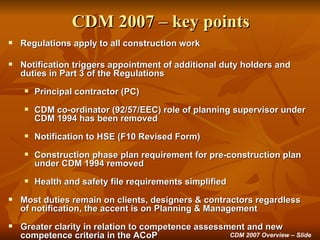

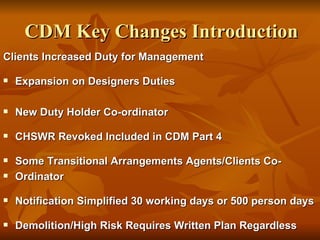

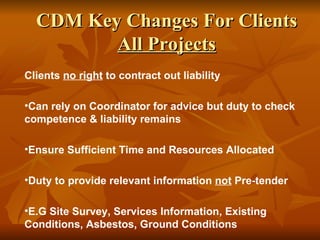

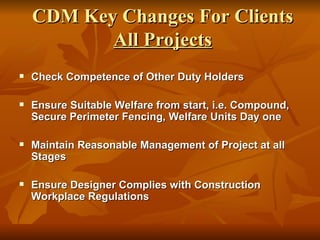

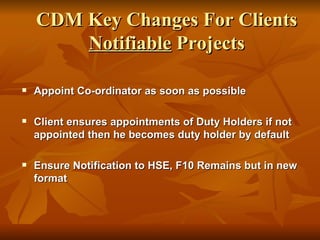

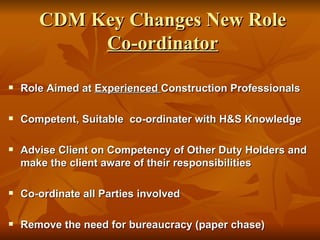

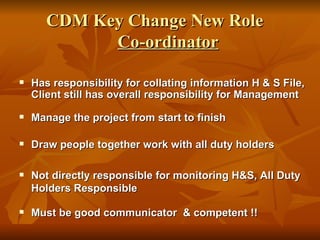

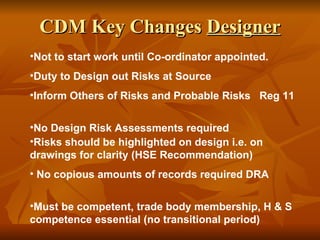

The document discusses key changes to the Construction Design and Management (CDM) regulations between 1994 and 2007 in the UK. It notes that CDM 1994 identified new duties for clients and designers but did not fully deliver on improving health and safety. CDM 2007 aimed to simplify the regulations, strengthen coordination requirements, and focus on planning and management rather than paperwork. Key changes included removing the planning supervisor role and introducing the new role of coordinator to assist the client, as well as adjusting notification thresholds.