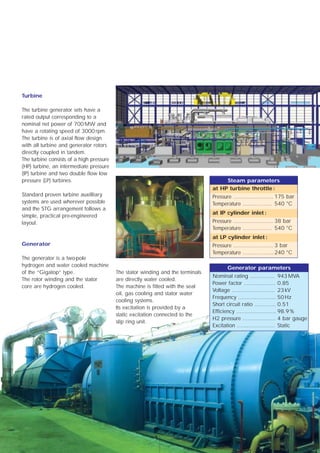

The document summarizes a project to build a 3 x 700 MW thermal power plant in Manjung, Malaysia. A consortium including Alstom Power and Peremba was awarded the contract in 1999. Alstom was responsible for the power block design, equipment, construction, commissioning and training. Peremba handled the civil works of auxiliary buildings and electrical/control equipment. Koch supplied the coal yard equipment. The plant utilizes an Alstom seawater flue gas desulphurization system and is located 10km from Lumut on a reclaimed island.