James M. Marshall has over 40 years of experience leading manufacturing operations and driving business turnarounds. He is skilled at implementing lean techniques like 5S, JIT, and Six Sigma to reduce costs and improve productivity. Marshall has held executive roles with companies in various industries, helping them improve profitability through process optimization, team building, and metric-driven performance.

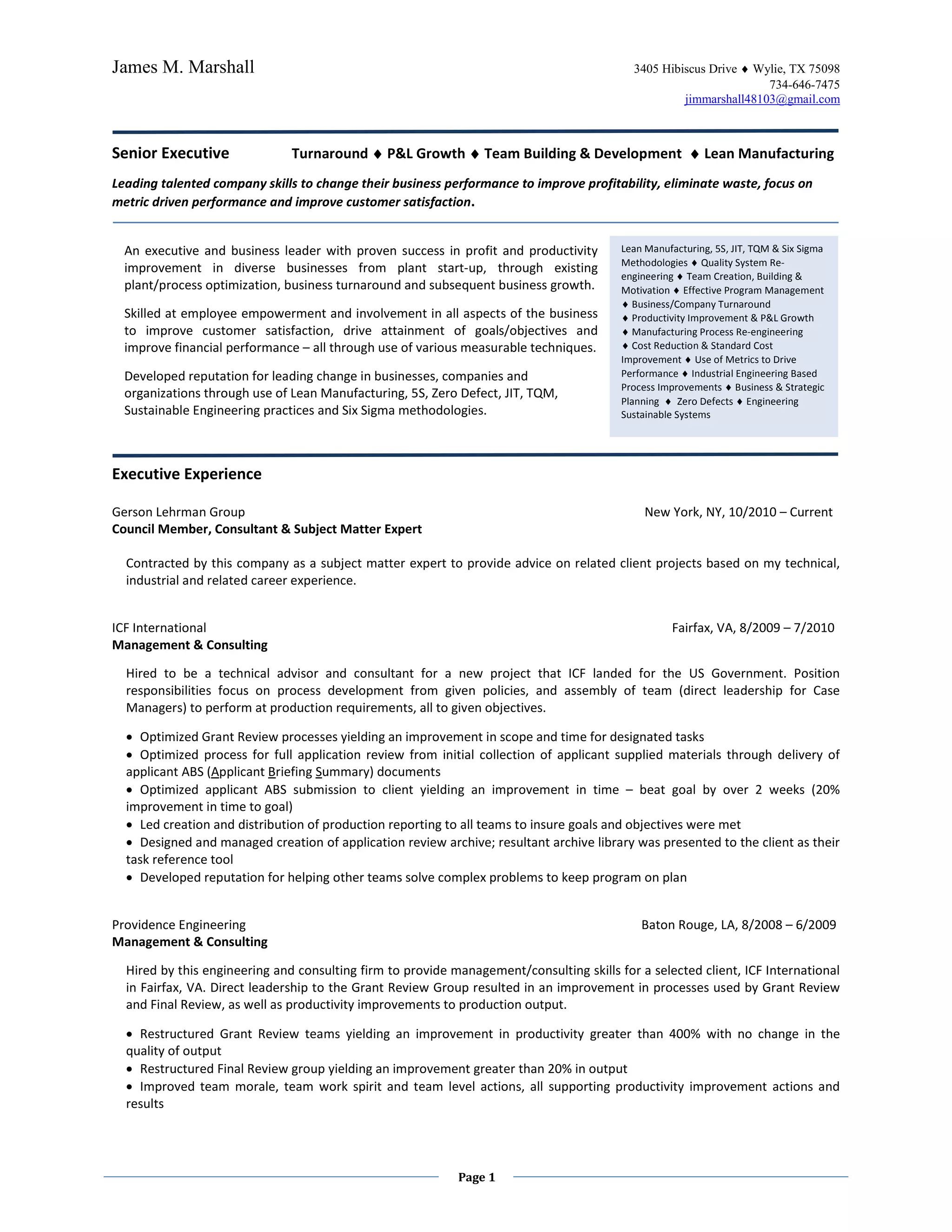

![James M. Marshall 3405 Hibiscus Drive ♦ Wylie, TX 75098

734-646-7475

jimmarshall48103@gmail.com

Walker Manufacturing (Division of Tenneco) Harrisonburg, VA, 5/1986 – 12/1988

Manufacturing Manager

Hired into new position at the Harrisonburg plant to drive productivity improvement programs. Managed all manufacturing,

engineering, plant inventories, current and future quality programs, employee involvement programs and cost reduction

activities.

• Improved plant productivity by 24%

• Implemented 'Quality Circles' and ‘TAP’ teams [productivity improvement teams]

• Implemented SPC programs/teams & use of Taguchi [designs of experiment]

• 1986 cost reduction - $3,100,000; 1987 cost reduction - $2,585,000

Eaton Corporation Cleveland, OH, 8/1972 – 5/1986

Various positions held during career with Eaton Corporation in the Axle & Brake Division manufacturing heavy duty truck

axles and brakes. Positions held from most recent through beginning were Manager of Manufacturing Services (Gallatin, TN),

Manager of Ind./Mfg. Eng. (Henderson, KY), Manager of Ind./Mfg. Eng. (Cleveland, OH), Plant Superintendent (Cleveland,

OH), Manager of Plant Engineering (Cleveland, OH), Manager of Divisional Plant Engineering (Cleveland, OH), Supervisor of

Facilities Planning (Cleveland, OH), Division Packaging Engineer (Cleveland, OH), and Industrial Engineer (Cleveland, OH).

Education

BS/BA, Management, Cleveland State University, Cleveland, OH

Undergraduate studies in Industrial/Mechanical Engineering, GMI & CSU prior to graduation

Coop Student & Management/Engineer Trainee - General Motors Corporation, Parma, Ohio

Page 4](https://image.slidesharecdn.com/jmarshallresume010912-130116061724-phpapp01/85/J-marshall-resume-010912-4-320.jpg)