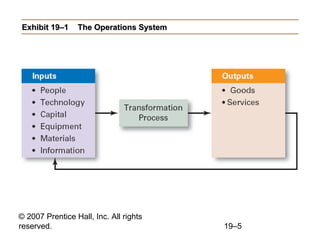

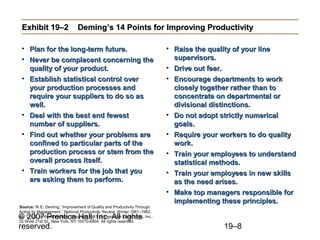

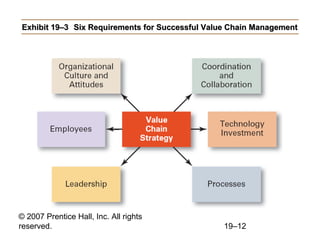

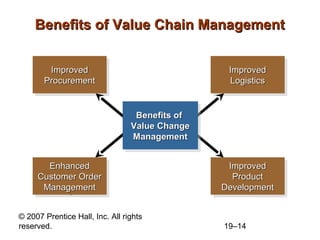

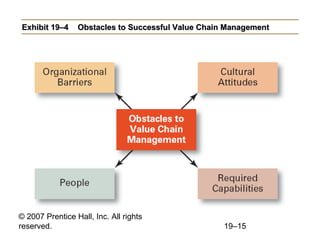

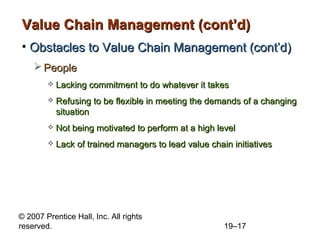

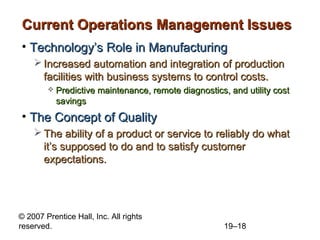

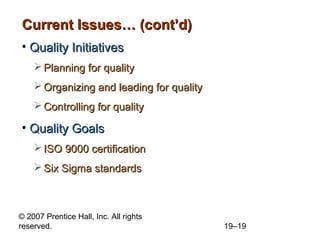

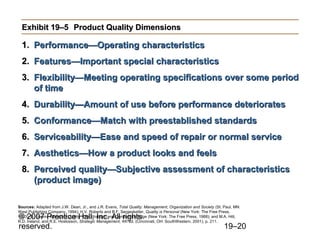

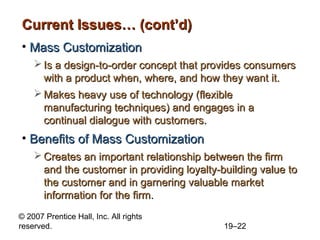

The document summarizes key concepts from a chapter on operations and value chain management. It discusses how operations management involves designing and controlling processes to transform resources into goods and services. Value chain management aims to integrate all members of the production process into a seamless chain that maximizes customer value. Successful value chain management requires coordination, technology investment, flexible employees and culture changes. Benefits include improved procurement, logistics, customer service and product development, while obstacles can include organizational barriers and lack of trust between members.