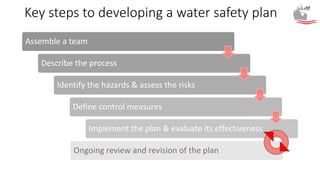

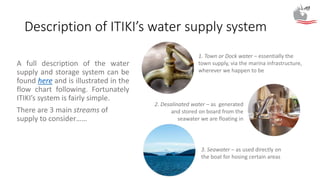

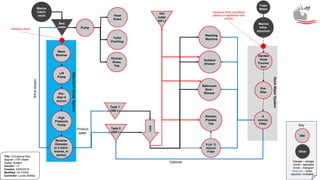

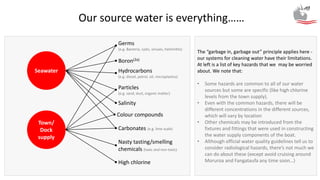

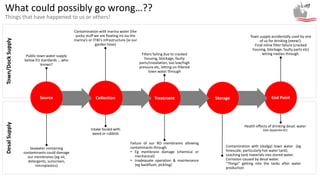

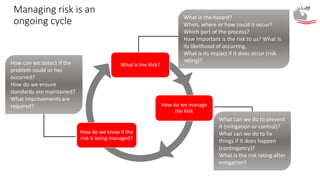

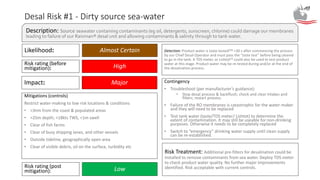

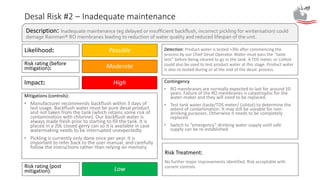

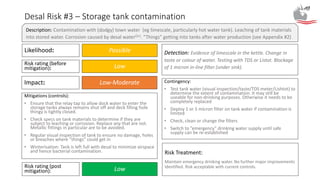

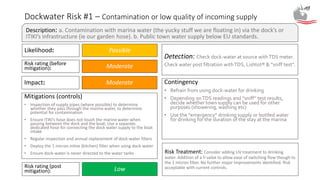

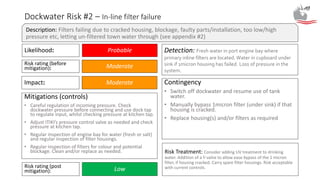

Itiki's Water Safety Plan aims to ensure the safety and acceptability of its drinking-water supply by following WHO guidelines and conducting a comprehensive risk assessment. The plan defines key steps for developing a water safety strategy, identifies potential hazards and risks, and outlines control measures to manage those risks. Ongoing review and testing are emphasized, along with the necessity for improved monitoring and maintenance to address various risks associated with water supply and treatment systems.

![References

(1) Water safety plan manual (WSP manual), Step-by-step risk management for drinking-water suppliers; WHO 2009

https://www.who.int/water_sanitation_health/publications/publication_9789241562638/en/

(2) Safe Drinking-water from Desalination; WHO 2011; WHO/HSE/WSH/11.03

https://www.who.int/water_sanitation_health/publications/desalination_guidance/en/

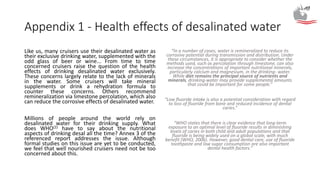

(a) Although boron is an essential element for plant growth, it is herbicidal at higher levels, and some plants are sensitive at 0.5 mg/l.

(b) The taste threshold is in the region of 200–250 mg/l, depending upon the associated anions

(c) Desalinated water is initially more corrosive [to metals] than many other drinking-water sources.

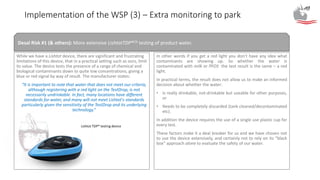

(3) Lishtot Test Drop Pro ®

https://www.lishtot.com/Water-testing-kit.html

https://www.lishtot.com/ListOfDetectableContaminants.pdf](https://image.slidesharecdn.com/itikiwsprevbadfinalro-200211103627/85/ITIKI-s-Water-Safety-Plan-23-320.jpg)