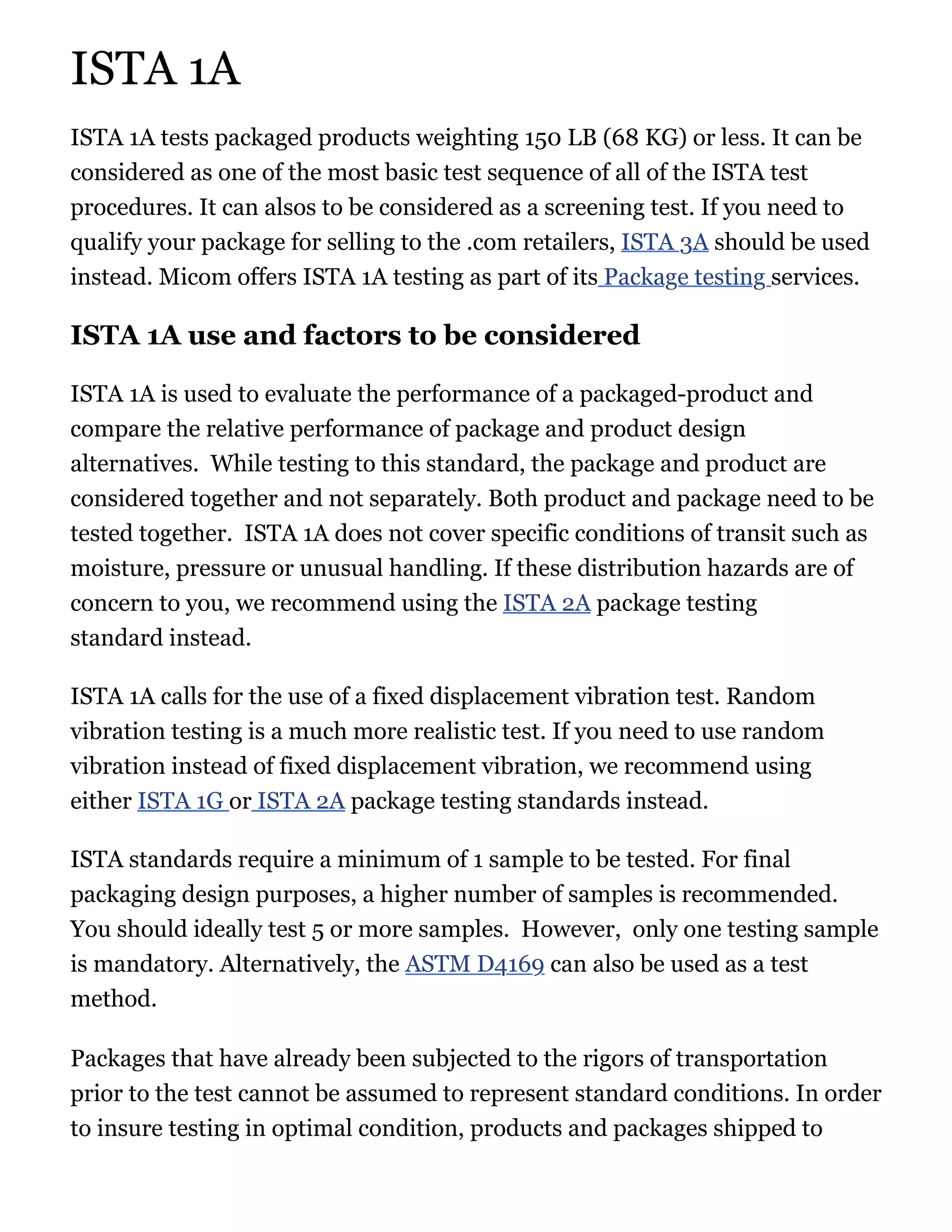

ISTA 1A is a basic testing procedure for packaged products weighing 150 lb or less, used to evaluate package and product performance together. It does not address transit conditions like moisture or pressure; for specific concerns, ISTA 2A is recommended. Testing typically requires a minimum of one sample, with five or more preferred for final designs, and follows a fixed displacement vibration test sequence.