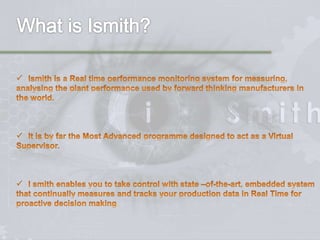

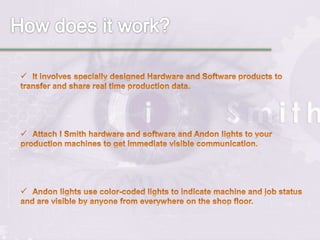

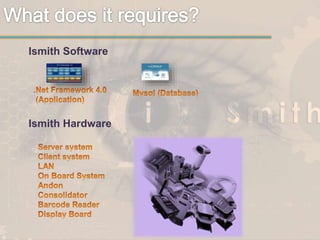

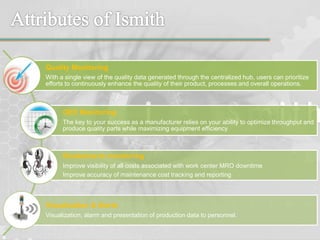

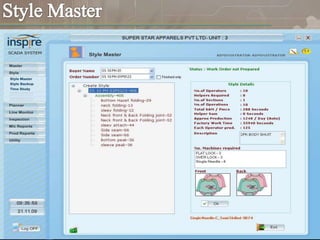

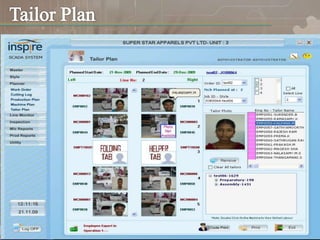

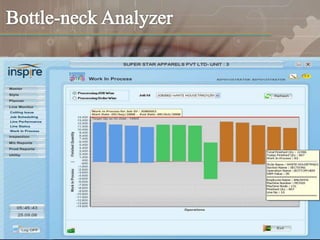

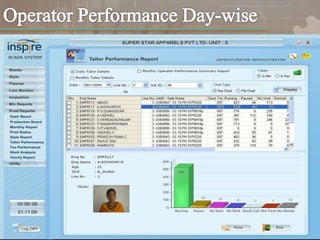

This document describes the features and benefits of Ismith's real-time monitoring system for manufacturing. The system allows users to generate standard or custom reports on a scheduled basis, monitor key performance indicators and production trends in real time, view quality and equipment efficiency data in a centralized hub, and improve visibility into maintenance costs and downtime issues. It captures all relevant production data automatically without paperwork, providing instant feedback and alerts, unlike traditional monitoring systems which have inaccurate, slow data collection.