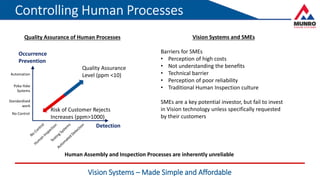

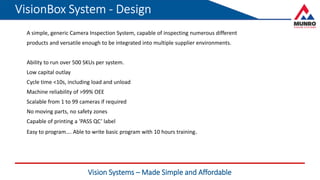

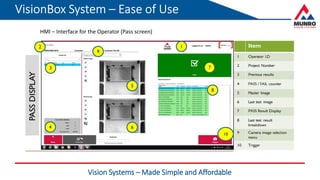

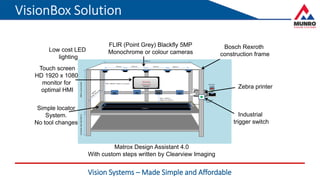

The document discusses the development of affordable vision systems for automated inspection, addressing the barriers faced by SMEs, such as cost perception and understanding benefits. It emphasizes the reliability and efficiency of camera inspection systems with minimal training requirements, highlighting their ability to handle multiple products and reduce labor costs. Ultimately, it advocates for the adoption of vision technology to enhance quality assurance in manufacturing processes.