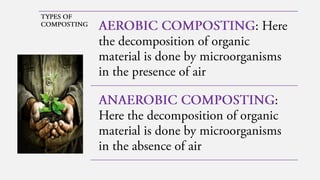

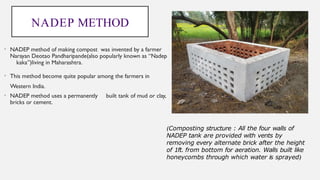

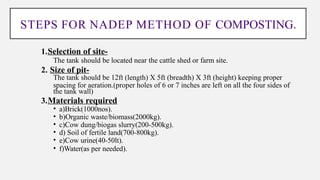

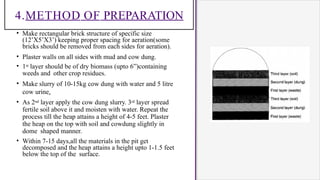

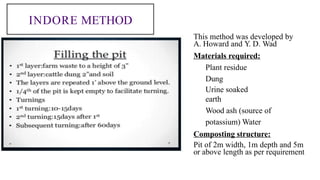

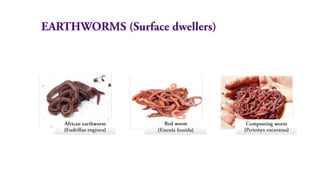

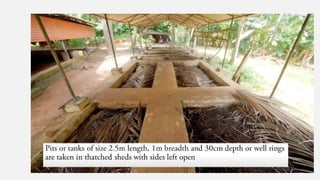

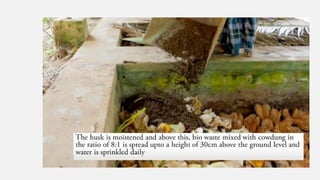

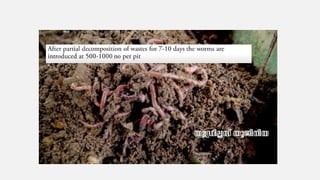

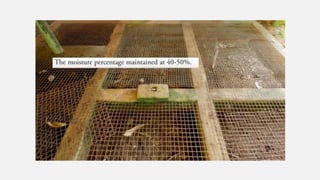

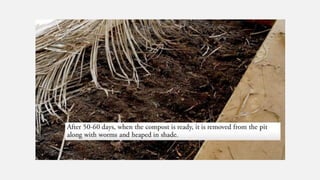

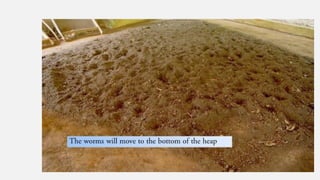

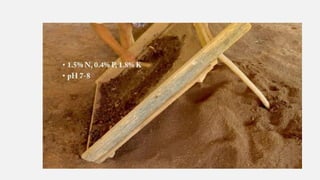

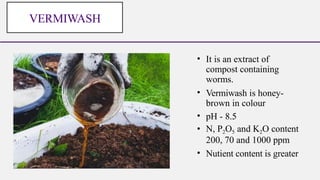

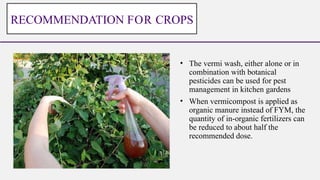

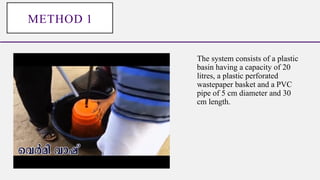

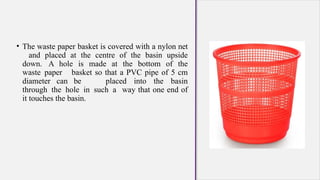

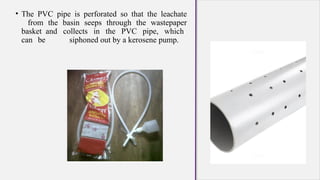

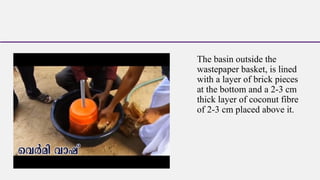

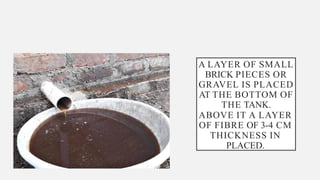

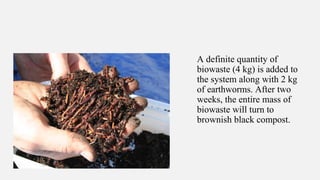

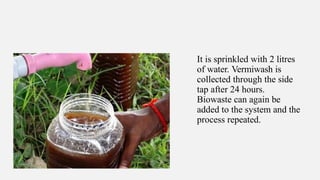

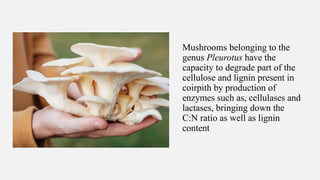

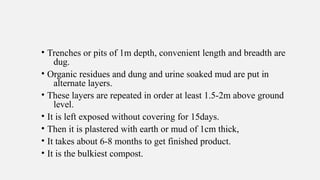

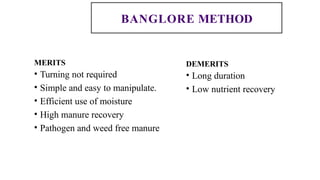

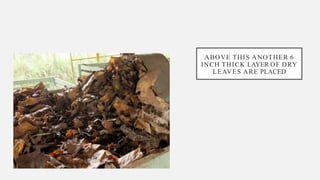

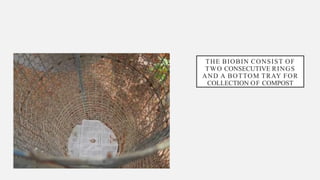

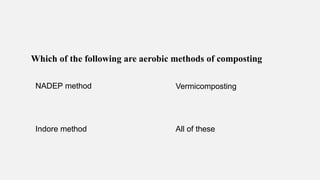

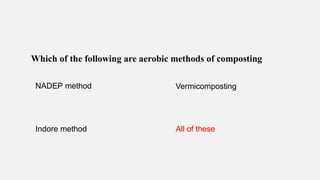

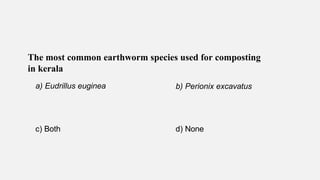

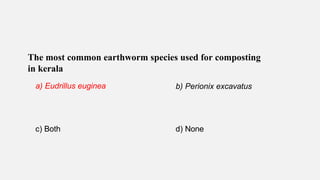

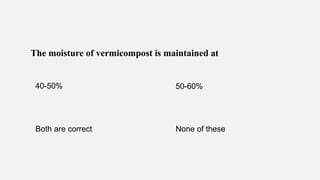

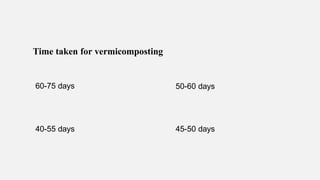

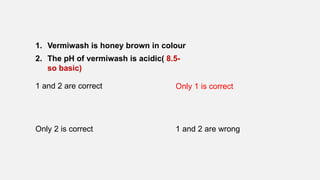

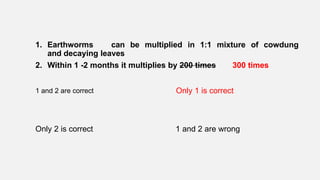

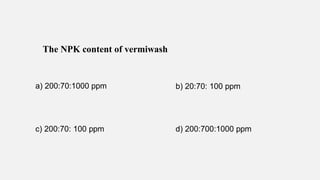

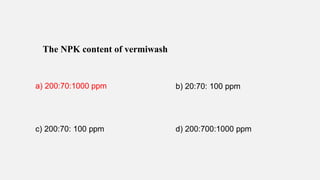

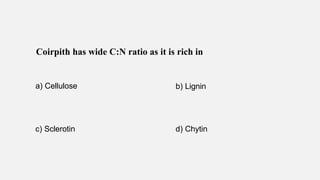

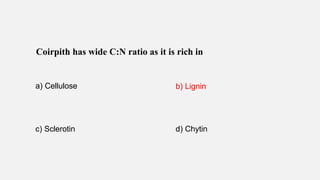

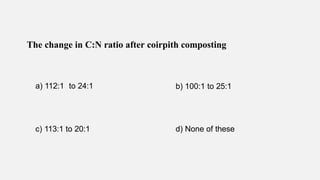

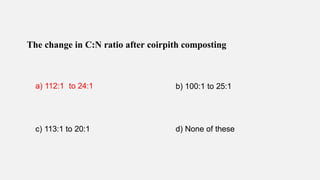

The document discusses organic waste, its types, and the benefits of organic recycling, including reducing landfill waste and greenhouse gas emissions by converting waste into compost and other products. Various composting methods, such as the Indore method and vermicomposting, are outlined, emphasizing their environmental advantages and economic potential. Additionally, the document highlights the importance of composting in improving soil health, conserving resources, and supporting local economies.