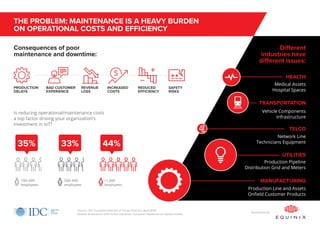

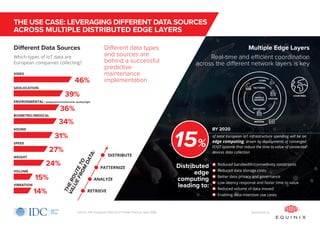

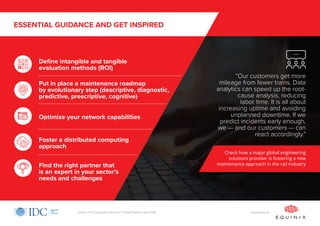

The document discusses the role of IoT in maintenance, emphasizing the transition from preventive to cognitive-enabled maintenance to reduce operational costs and enhance efficiency across various industries. It highlights the importance of leveraging diverse data sources and adopting a phased approach to utilize IoT effectively for predictive maintenance. The text also underscores the necessity of distributed edge computing in improving real-time data coordination and reducing downtime.