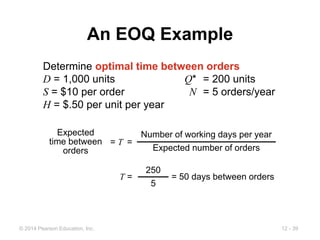

This document outlines key concepts related to inventory management. It begins with an overview of inventory management at Amazon, noting how Amazon has transitioned from a virtual retailer to a leader in warehousing and inventory management. It then discusses the economic order quantity (EOQ) model, which aims to minimize total inventory costs by balancing ordering and holding costs. The optimal order quantity is derived using the formula that sets ordering and holding costs equal. An example demonstrates how to apply the EOQ model to determine the optimal order quantity, expected number of orders per year, and time between orders.