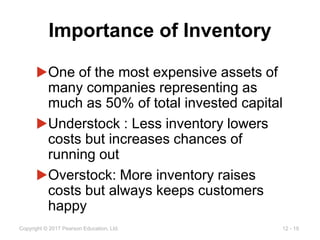

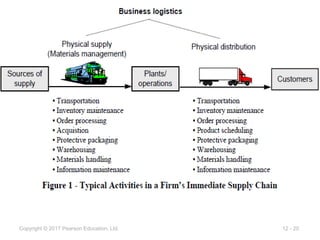

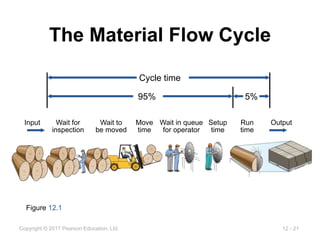

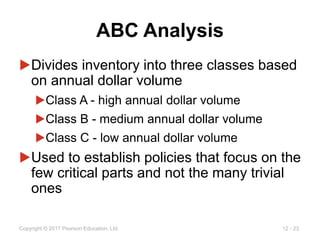

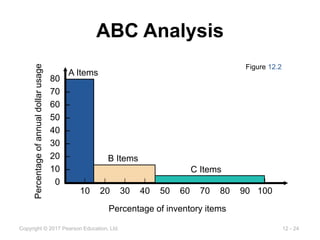

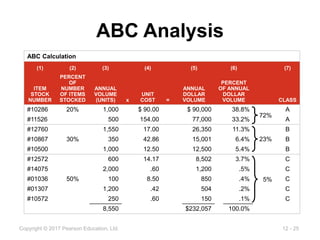

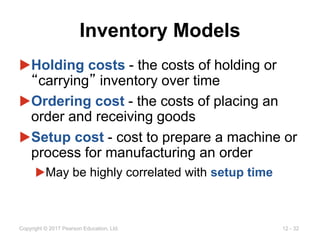

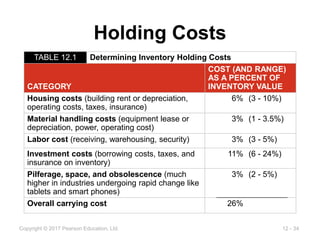

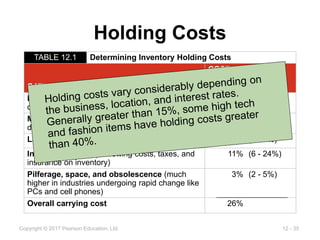

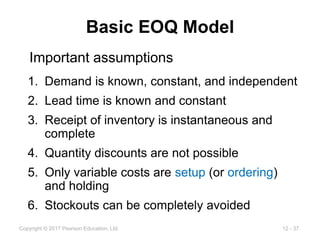

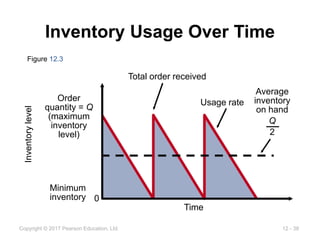

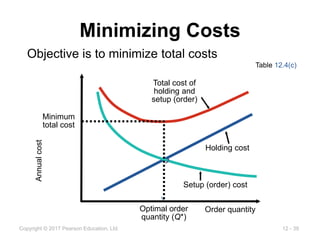

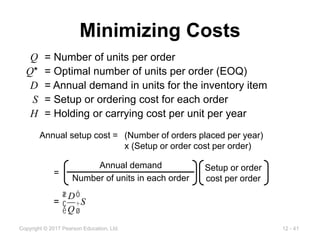

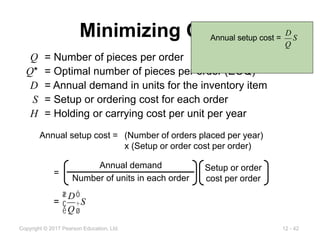

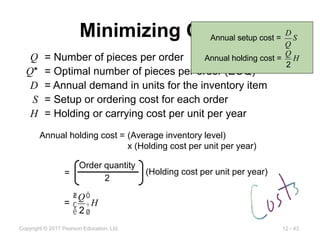

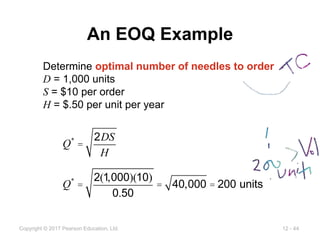

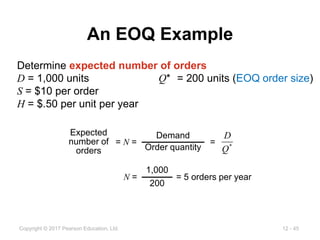

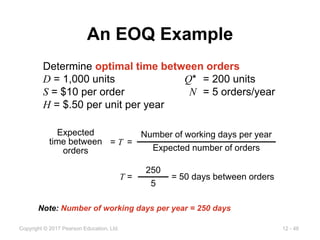

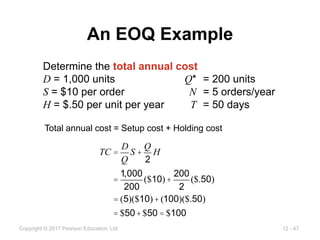

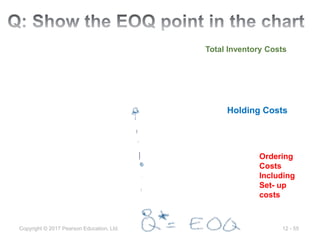

The document provides an overview of inventory management concepts including the economic order quantity (EOQ) model. It begins by explaining the objectives and importance of inventory management. It then discusses inventory classification methods like ABC analysis which divides inventory into categories based on annual dollar volume. The document also covers record accuracy and inventory models. A key focus is on the basic EOQ model which aims to minimize total inventory costs by balancing setup and ordering costs with holding costs. The optimal order quantity is determined by setting these costs as equal. Worked examples are provided to illustrate how to calculate optimal order quantity using the EOQ formula.