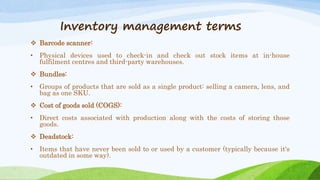

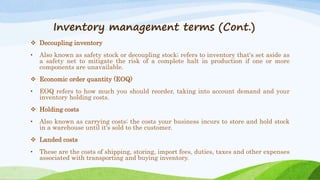

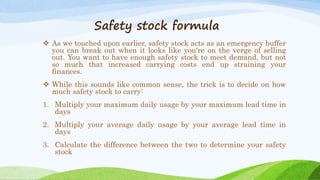

Inventory management helps companies track inventory from purchase to sale in order to ensure there are sufficient stock levels to meet customer demand. It aims to balance having enough inventory without overstocking, which ties up cash. Effective inventory management requires identifying trends to time orders correctly and prevent stockouts. Formulas can help calculate optimal reorder points, safety stock levels, and order quantities. Demand planning is also important for inventory management to project future requirements.