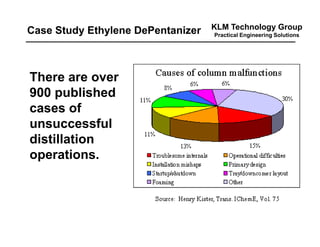

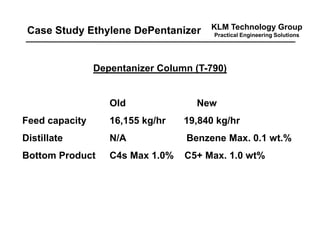

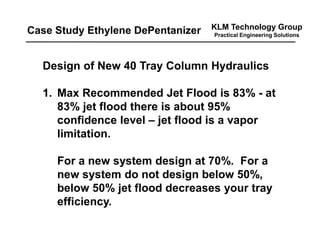

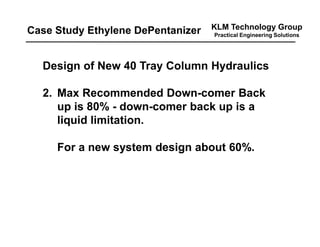

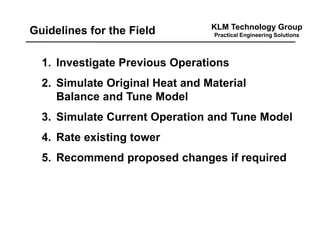

KLM Technology Group provides engineering consulting services and training. It has been operating since 1995 based in the USA. It offers various training courses related to process simulation and chapters from its Kolmetz Handbook of Process Equipment Design on topics like distillation design. The presentation discusses an introduction to process simulation including guidelines for using simulation effectively and a case study on simulating an ethylene depentanizer column.