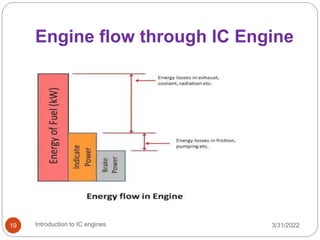

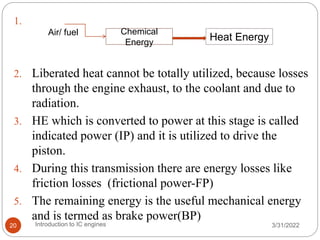

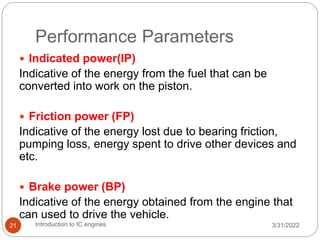

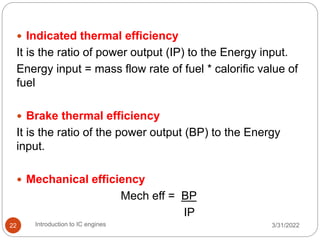

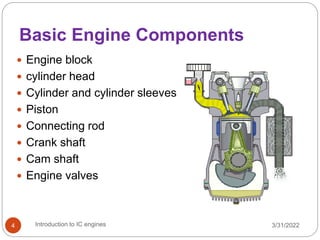

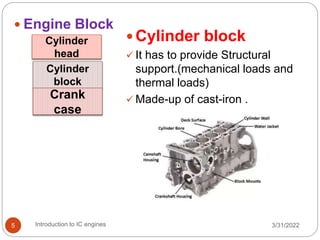

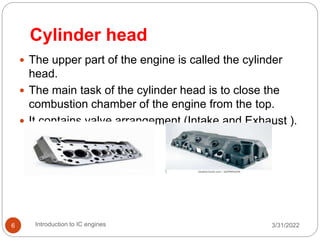

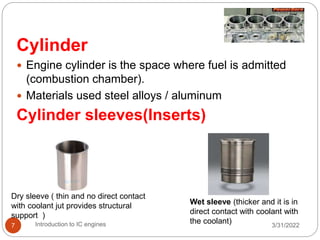

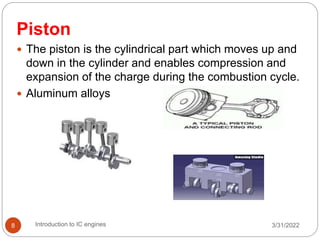

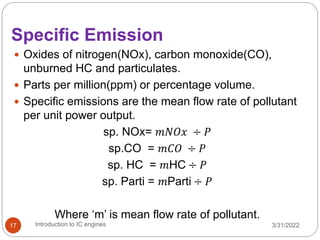

The document is a presentation on internal combustion (IC) engines, detailing their basic components, auxiliary systems, and various performance parameters. Key components include the engine block, cylinder head, piston, and crankshaft, all of which play vital roles in energy transformation and mechanical motion. The presentation also discusses emissions, applications in various fields, and crucial performance metrics such as indicated power, brake power, and thermal efficiency.

![Emission Index

Emission rates can be normalized by fuel flow

rate i.e emission index.

EI (NOx) =[ m(NOx)÷ 𝑚(𝑓𝑢𝑒𝑙)]

EI (CO) =[ m(CO)÷ 𝑚(𝑓𝑢𝑒𝑙)]

Why it is ,

The total amount of a pollutant emitted from an

emission unit during a given time period.

3/31/2022

Introduction to IC engines

18](https://image.slidesharecdn.com/introductiontoicenginespart1-220331075002/85/introduction-to-IC-Engines-pptx-18-320.jpg)