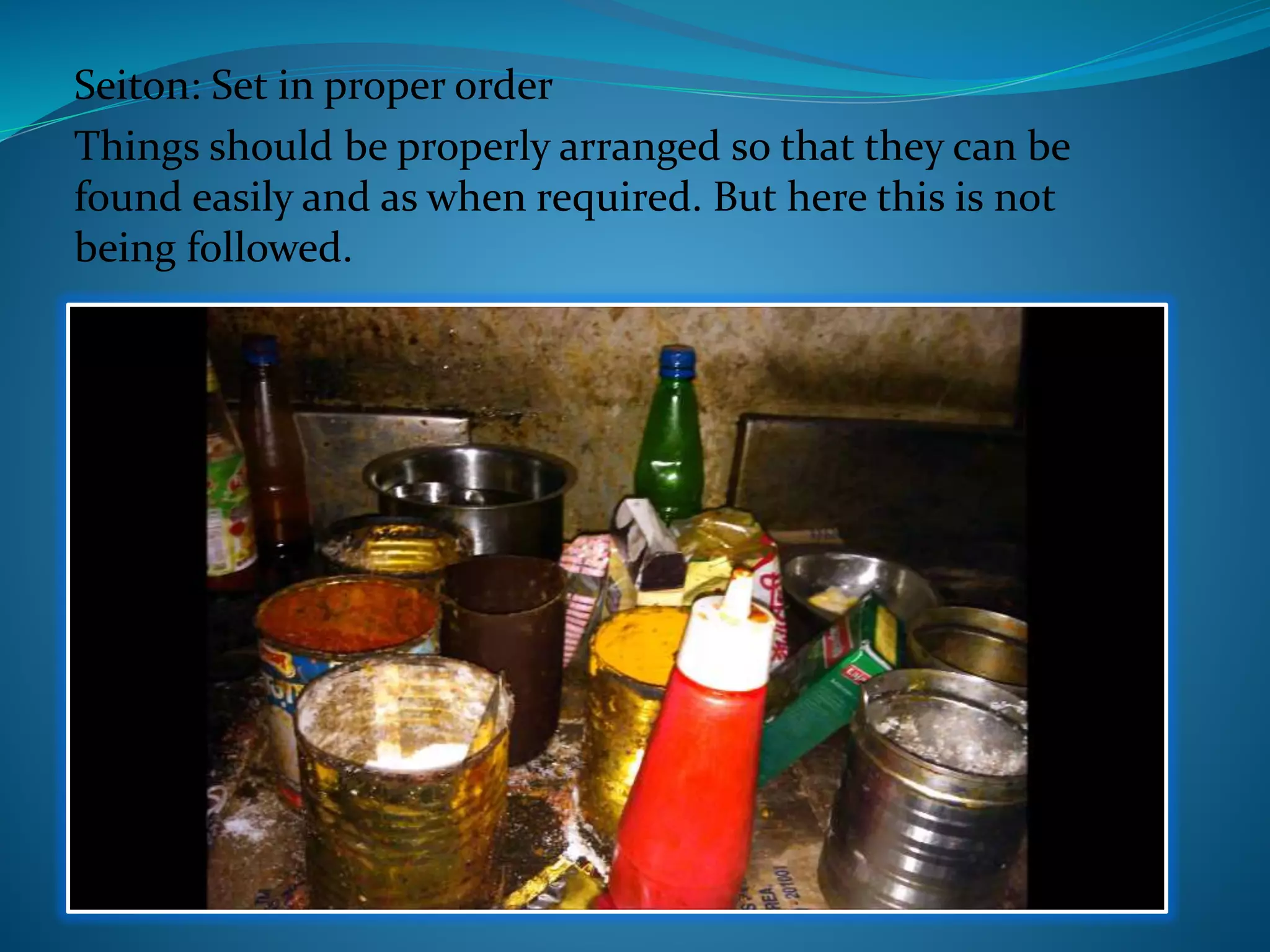

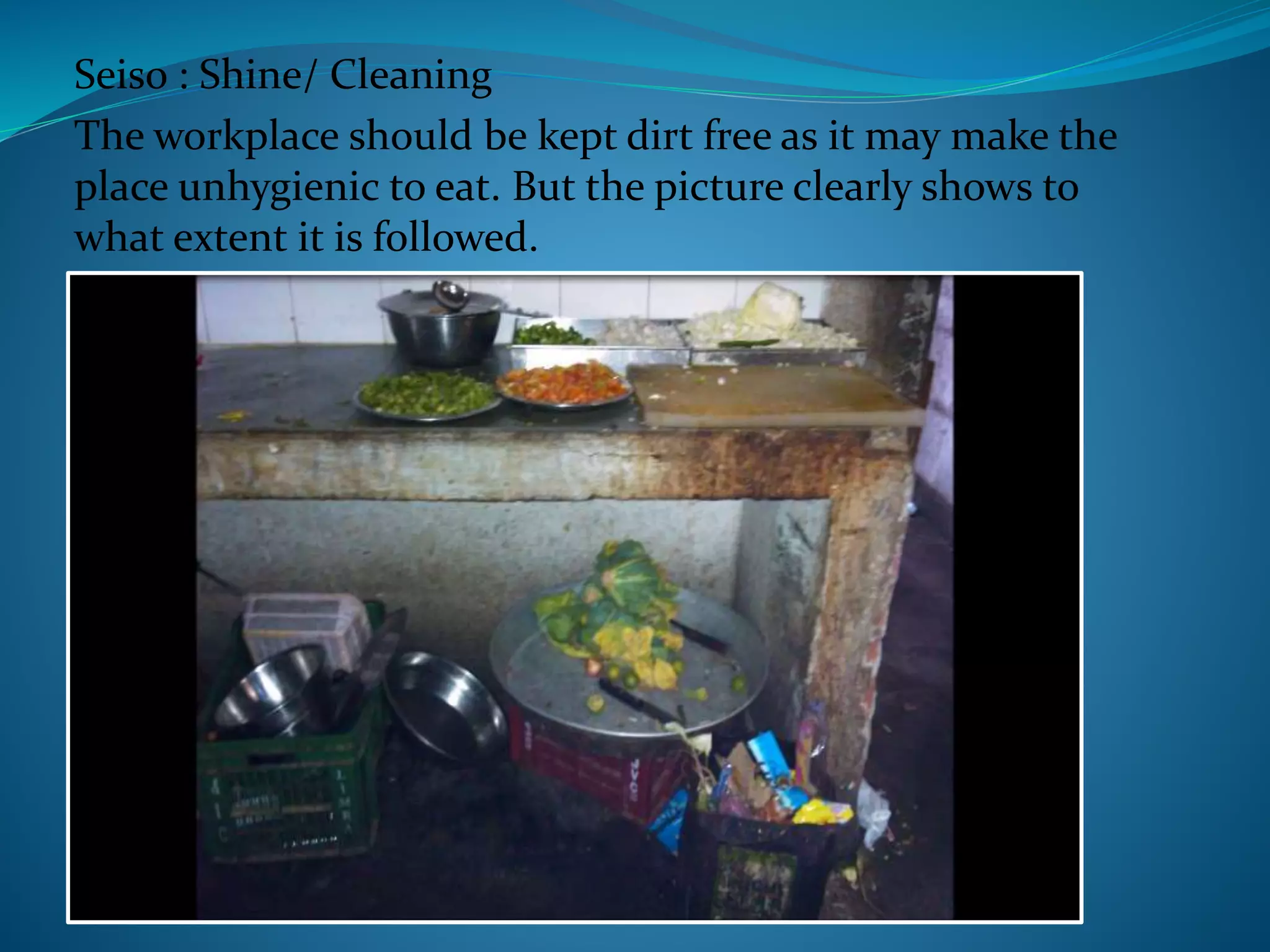

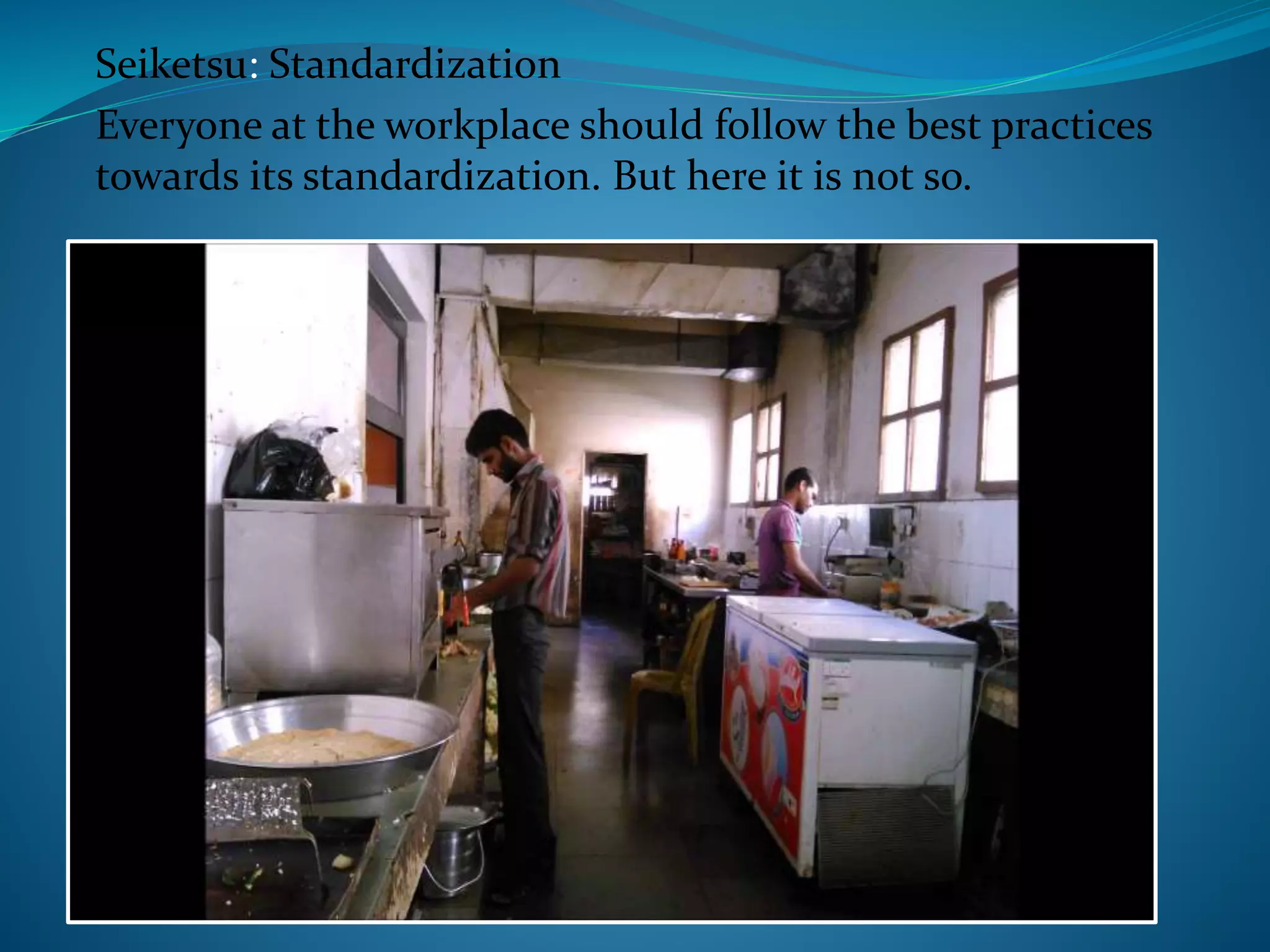

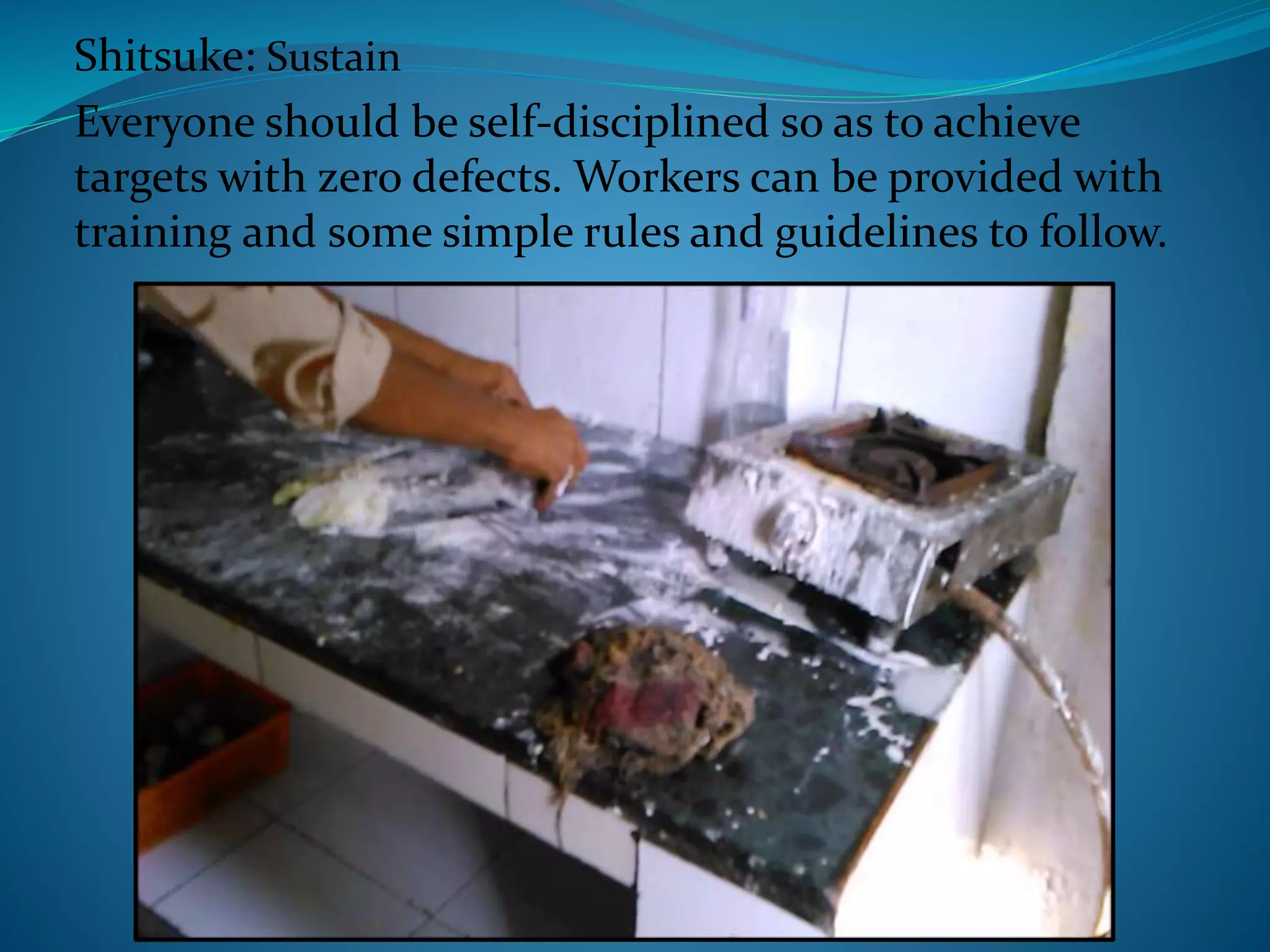

The document discusses the 5S methodology for creating a clean and organized workplace, outlining its five components: Seiri (sort), Seiton (proper arrangement), Seiso (shine/cleaning), Seiketsu (standardization), and Shitsuke (sustain). It highlights poor practices currently in the workplace, such as disorganized items, lack of cleanliness, absence of standardization, and failure in sustaining hygiene. Recommendations for improvement include sorting items, proper arrangement, regular cleaning, and training for workers on hygiene and organizational standards.