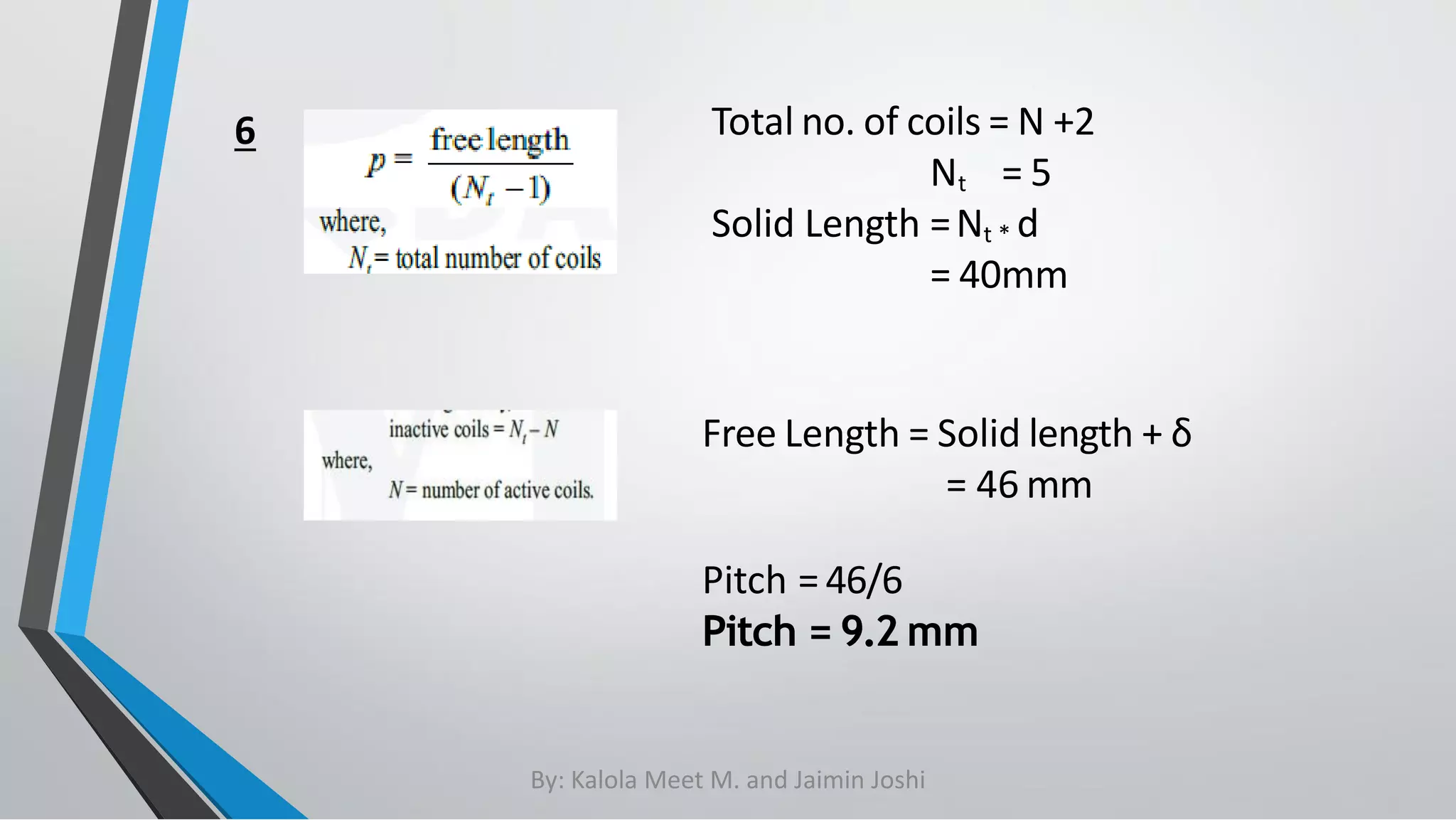

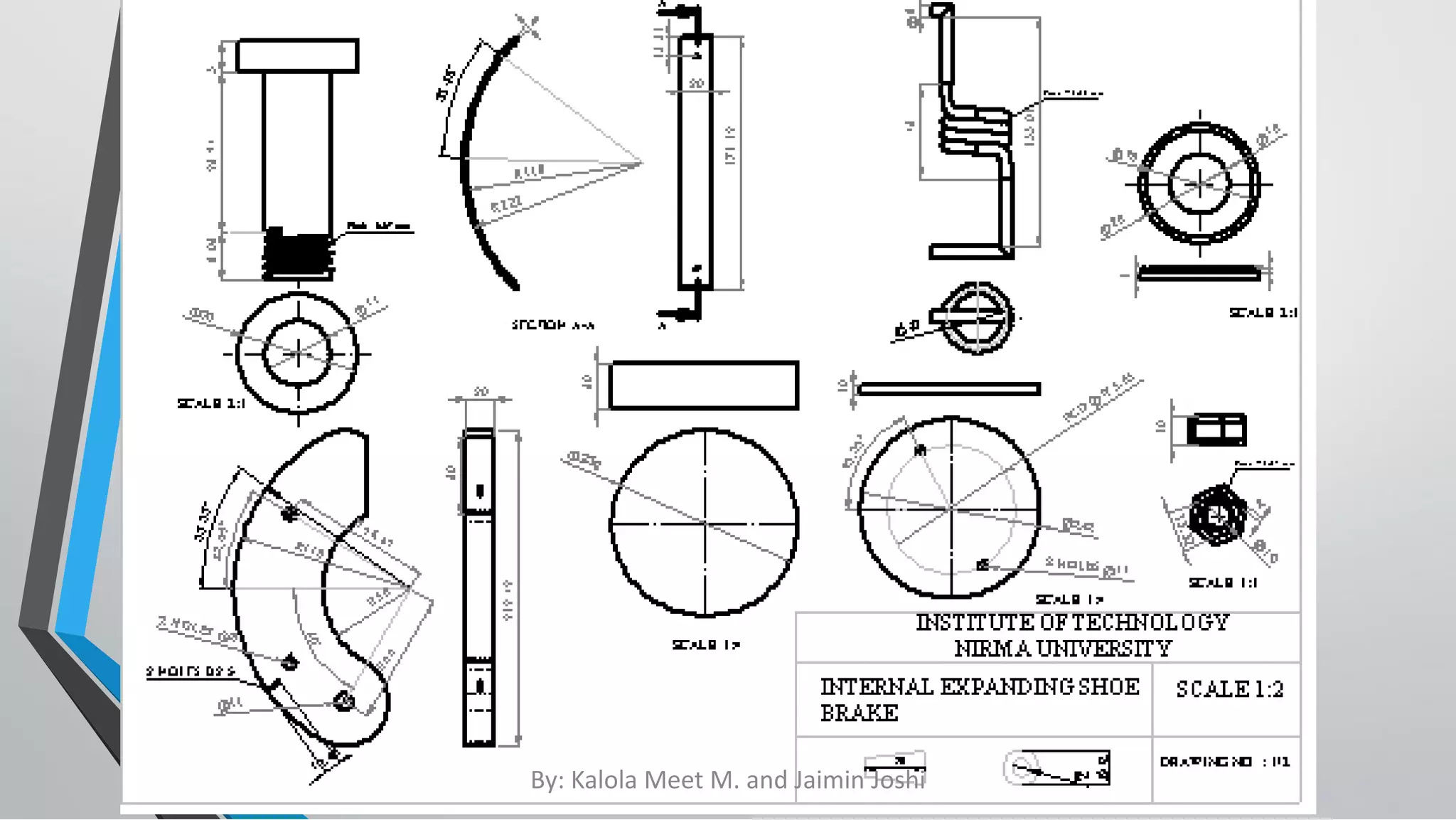

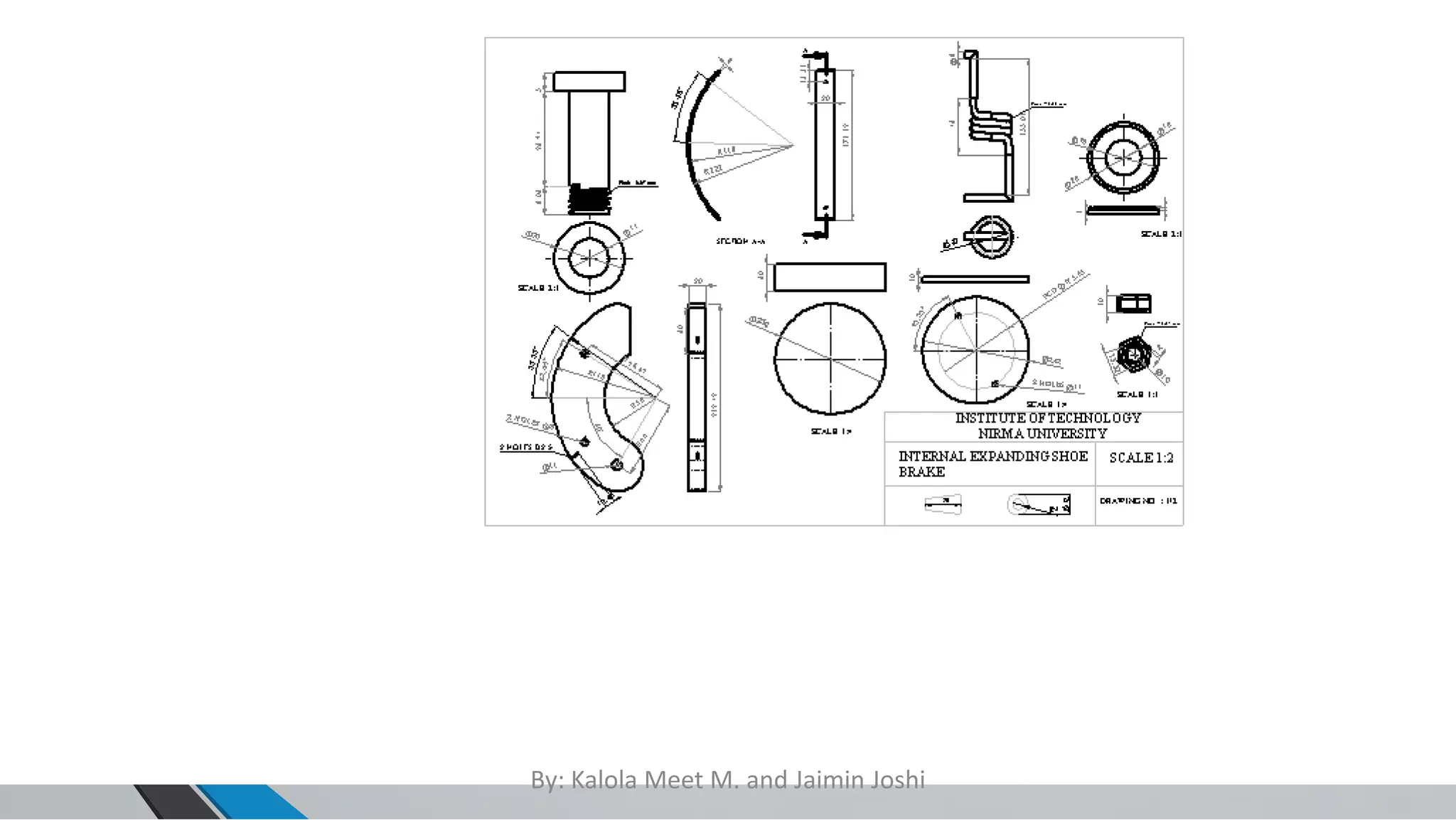

The document discusses the twin leading shoe drum brake system, commonly used for effective forward braking in vehicles, particularly motorcycles. It outlines the design, assumptions, calculations for stress and torque, and the construction of the brake system, including components such as drum, shoes, and springs. The document concludes with references for further information on materials and design principles.