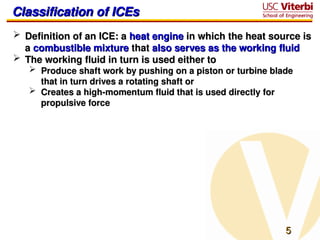

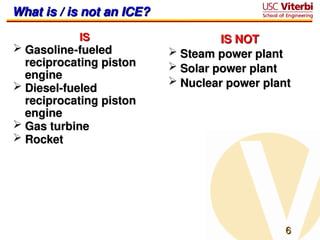

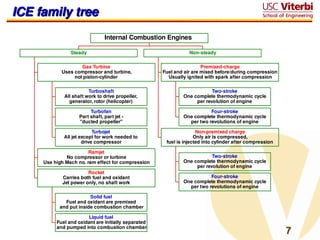

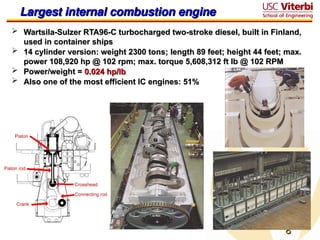

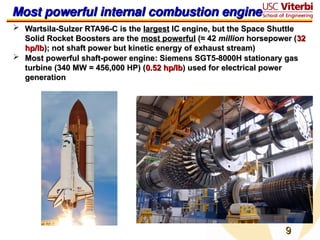

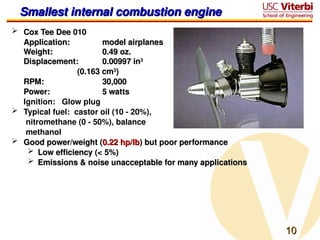

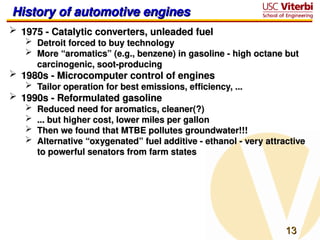

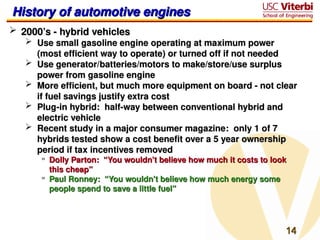

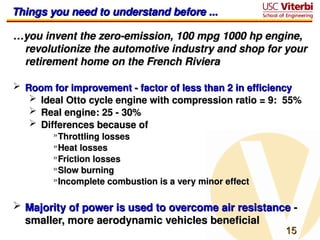

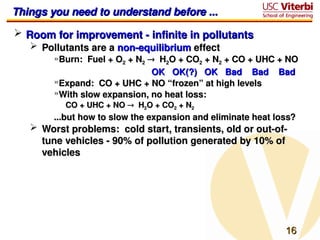

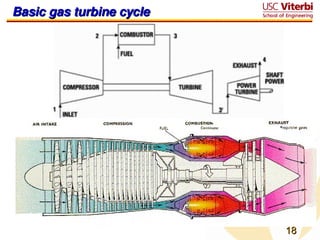

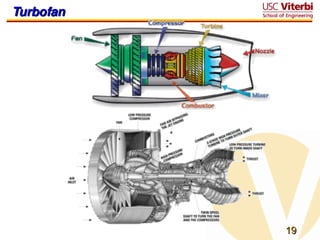

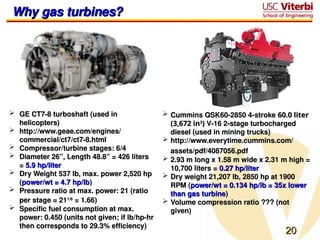

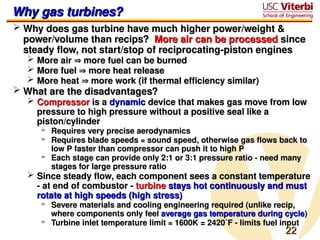

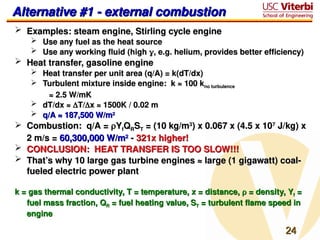

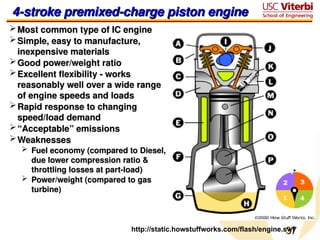

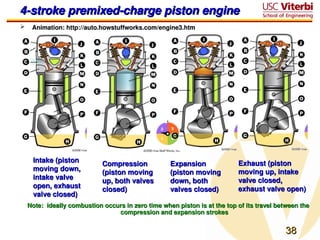

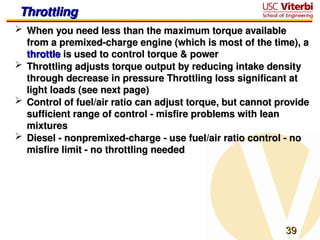

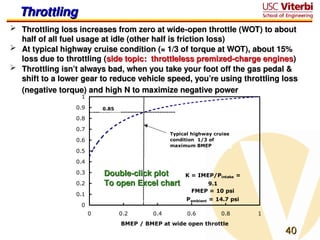

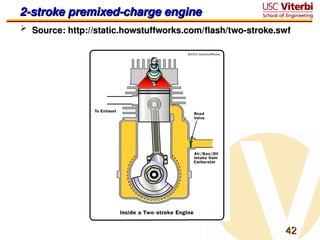

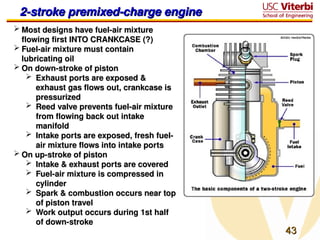

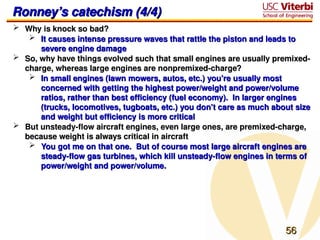

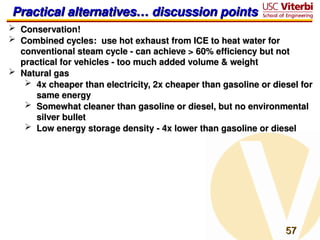

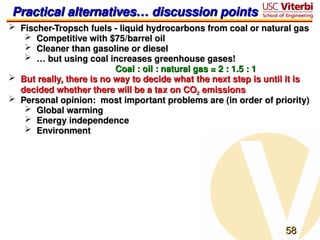

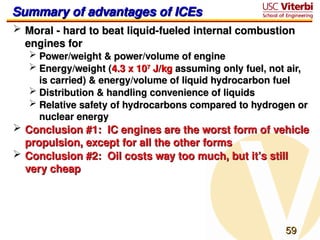

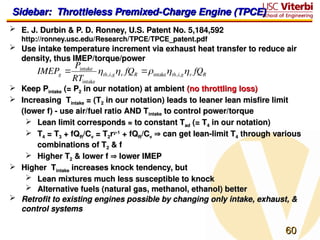

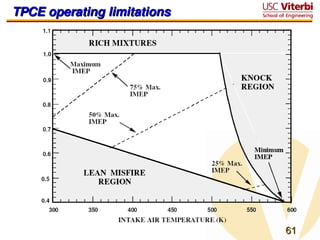

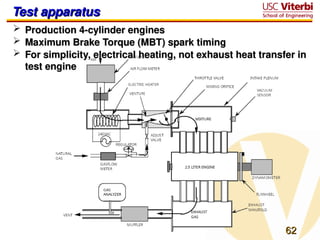

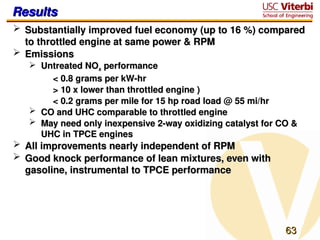

This document is a presentation that discusses internal combustion engines (ICEs), their definitions, types, and historical evolution, as well as their prevalence and challenges associated with replacing them. It outlines the mechanics of ICEs, provides insights into alternatives like gas turbines, and emphasizes the complexities of improving engine efficiency and reducing emissions. Additionally, it highlights the latest developments in hybrid vehicles and the impact of regulations on engine technology.