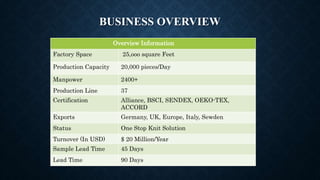

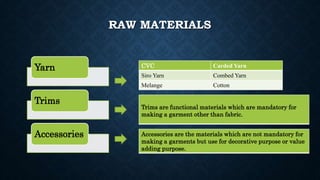

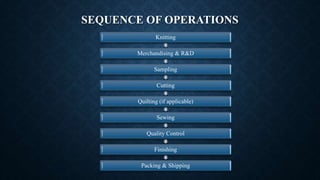

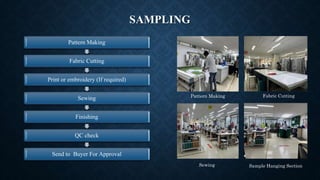

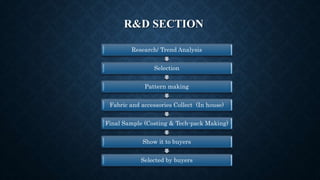

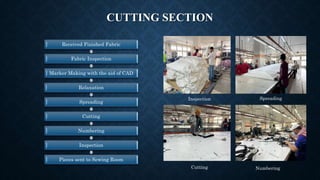

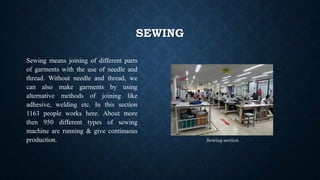

Green Life Knit Composite Ltd. is a knit manufacturer in Bangladesh established in 2010 with over 2400 employees across a 25,000 square foot factory. It produces around 20,000 pieces per day of items like t-shirts, hoodies, and sportswear for customers in Germany, UK, Europe, Italy, and Sweden. The factory utilizes over 950 sewing machines and 40 knitting machines across processes like knitting, sampling, cutting, sewing, finishing, and packaging to transform raw materials like yarn and trims into finished goods for over $20 million in annual sales. An industrial training at the factory provided hands-on experience in textile production, management, and gaining practical knowledge to complement theoretical education.