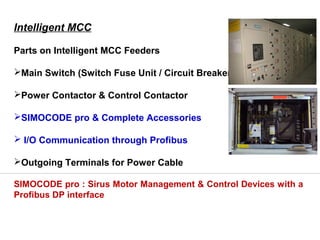

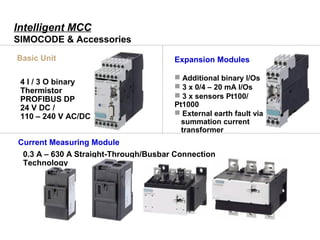

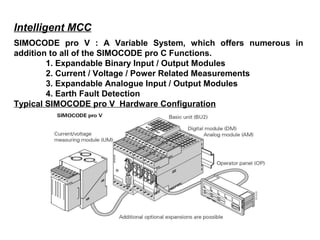

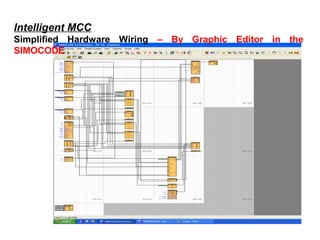

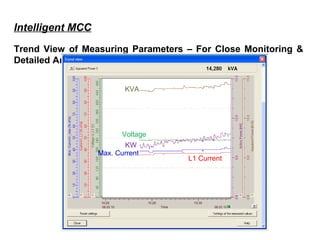

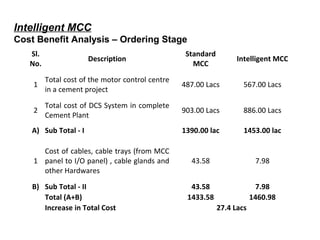

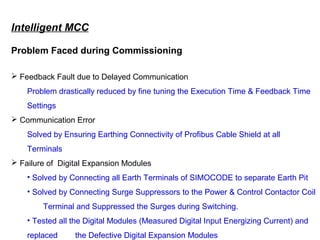

The document describes an intelligent motor control center (MCC) system using SIMOCODE motor management and control devices. Key advantages of the intelligent MCC include sensitive motor protection, direct communication to DCS for monitoring and control, reduced commissioning time, and online monitoring of motor parameters. While the upfront cost is higher, the intelligent MCC provides benefits like reduced installation, commissioning and maintenance costs over traditional MCCs. Some initial problems during commissioning centered around communication delays and errors but were addressed through configuration and hardware changes.