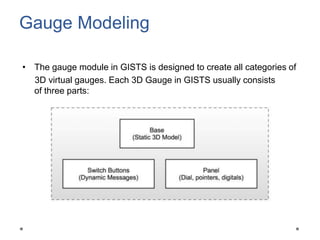

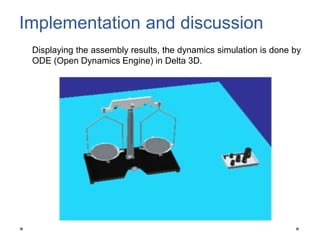

The document discusses the integration of virtual laboratories into science e-learning, focusing on the design and implementation of a virtual lab system called GISTS. It outlines the methodologies used to create interactive tools for students to engage in experimental learning through 3D environments and simulations. The study aims to enhance educational experiences by providing low-cost alternatives to physical laboratories and proposes future improvements for better integration with learning management systems.