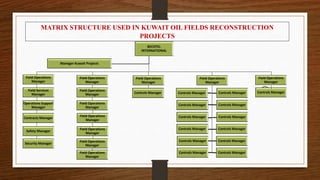

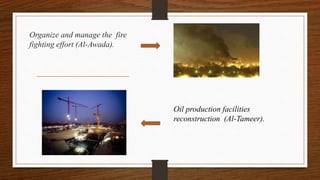

The document discusses the reconstruction of Kuwait's oil fields following the Gulf War. It describes the matrix structure used to manage the various projects, including appointing field operations managers to oversee individual sites. International relationships were important and handled through recruiting foreign laborers, political support, supply chains, knowledge sharing, importing materials, and technology transfer. The Al-Awada project to organize firefighting efforts and clear hazardous materials was identified as most important to enable subsequent reconstruction work to proceed safely.