The document provides installation instructions for an air conditioner. It includes:

- Safety precautions that must be followed to prevent injury and property damage during installation.

- An installation process outline listing the order of installation steps.

- Specifications for different outdoor unit models including dimensions, refrigerant amounts, and connection pipe sizes.

- Instructions on site selection, unit installation, refrigerant piping, electrical wiring, test runs, and other installation procedures.

![Installation Space

Installation Space

• The following values are the least space for installation.

If any service area is needed for service according to field circumstance, obtain enough service space.

• The unit of values is mm.

■ In case of obstacles on the suction side

1. Stand alone installation

10

mo 0 or

r re

0o 10 0o

r

10 ore mo 0 or 10 ore

m re m

les

s ss

r o r le

0o 00

50 5

1000 or

more

1000 or

more

15

r mo0 or

0o re

10 ore 15 0o

r

m mo0 or 15 ore

re m

[Unit:mm]

2. Collective installation

ss

r le

0o

1000 or

50

more

10 10

0 0

mo 0 or mo 0 or

re 10 re 10

mo 0 or mo 0 or

re re r

20

0o

r 20 0o

mo 0 or 30 ore mo 0 or

30 ore

m

re m re

[Unit:mm]

12 Outdoor Unit](https://image.slidesharecdn.com/installationmanualmini-130122114709-phpapp02/85/Installation-manual-mini-12-320.jpg)

![Installation Space

■ In case of obstacles on the discharge side

ENGLISH

1. Stand alone installation s

les

0 or

50

1000 or

more

re re

r mo r mo

0o 0o

50 50

s

les

0 or

2. Collective installation 50

1000 or more

10 10

mo 0 or mo 0 or

re re

re ore

r mo o rm

00o 10

00

10 [Unit:mm]

■ In case of obstacles on the suction and the discharge side

➲ Obstacle height of discharge side is higher than the unit

ss

1. Stand alone installation o r le

500

L>H L>H

1000 or

more

H

L

L

H

r

r 0o

0o 25 ore

10 ore or m

00

r

m 10 ore [Unit:mm]

0o e m

50 mor

Installation Manual 13](https://image.slidesharecdn.com/installationmanualmini-130122114709-phpapp02/85/Installation-manual-mini-13-320.jpg)

![Installation Space

2. Collective installation

s

les

0 or

50

1000 or

L>H L>H

more

H

L

10

L

0o 10

rm 0o

ore rm

r ore r

0o 0o

30 ore 30 ore

m m

ore

or orm

00 50

10 more 12

[Unit:mm]

➲ Obstacle height of discharge side is lower than the unit

1. Stand alone installation ss

r le

0o

50

1000 or

more

L≤H L≤H

H

H

L

L

r

0o

r 30 ore

0o or m

10 ore 00

r m 10 ore

0o m

50 ore

m

2. Collective installation

s

les

0 or

1000 or

more

50

L≤H L≤H

H

H

L

L

10 10

0o 0o

rm rm

ore ore

r or

0o 00

30

r more or 3 more

0o 00

150 ore 15 more [Unit:mm]

m

14 Outdoor Unit](https://image.slidesharecdn.com/installationmanualmini-130122114709-phpapp02/85/Installation-manual-mini-14-320.jpg)

![Installation Space

Collective / Continuous Installation for roof top use

ENGLISH

Space required for collective installation and continuous installation: When installing several units, leave space

between each block as shown below considering passage for air and people.

1. One row of stand alone installation

or

100 ore

r m

0o

200 ore

m

or

200 ore

r m

0o

100more [Unit:mm]

2. Rows of collective installation (2 or more)

• L should be smaller than H

L≤H

10

mo 0 or

L

re

or

300ore

r m

0o

300more

H

or

r 600ore

0o m

150 ore [Unit:mm]

m

Seasonal wind and cautions in winter

• Sufficient measures are required in a snow area or severe cold area in winter so that product can be operated well.

• Get ready for seasonal wind or snow in winter even in other areas.

• Install a suction and discharge duct not to let in snow or rain.

• Install the outdoor unit not to come in contact with snow directly. If snow piles up and freezes on the air suction hole,

the system may malfunction. If it is installed at snowy area, attach the hood to the system.

• Install the outdoor unit at the higher installation console by 50cm than the average snowfall (annual average snowfall) if

it is installed at the area with much snowfall.

1. The height of H frame must be more than 2 times the snowfall and its width shall not exceed the width of the

product. (If width of the frame is wider than that of the product, snow may accumulate)

2. Don't install the suction hole and discharge hole of the Outdoor Unit facing the seasonal wind.

Installation Manual 15](https://image.slidesharecdn.com/installationmanualmini-130122114709-phpapp02/85/Installation-manual-mini-15-320.jpg)

![Installation

Installation

Foundation for Installation

• Check the strength and level of the installation ground so that the unit will not cause any operating vibration or

noise after installation.

• Fix the unit securely by means of the foundation bolts. (Prepare 4sets of M12 foundation bolts, nuts and

washers each which are available on the market.)

• It is best to screw in the foundation bolts until their length are 20mm from the foundation surface.

Anti-vibration

Spring washer materials

Frame Nut Concrete Four bolt are

base required

H-Beam 3 thread ridges

75

75

200

200

100

[Unit:mm]

Foundation bolt executing method

16 Outdoor Unit](https://image.slidesharecdn.com/installationmanualmini-130122114709-phpapp02/85/Installation-manual-mini-16-320.jpg)

![Installation

Preparation of Piping

ENGLISH

Main cause of gas leakage is defect in flaring work. Carry out correct flaring work in the following procedure.

1) Cut the pipes and the cable. Copper

■ Use the accessory piping kit or the pipes purchased tube 90° Slanted Uneven Rough

locally.

■ Measure the distance between the indoor and the

outdoor unit.

■ Cut the pipes a little longer than measured distance.

■ Cut the cable 1.5m longer than the pipe length.

Pipe

Reamer

2) Burrs removal

■ Completely remove all burrs from the cut cross section

of pipe/tube. Point down

■ Put the end of the copper tube/pipe to downward

direction as you remove burrs in order to avoid to let

burrs drop in the tubing.

3) Flaring work

■ Carry out flaring work using flaring tool as shown right. Handle

Bar Bar

Unit : mm(inch) "A" Yoke

Indoor unit Pipe " A " Cone

[kW(Btu/h] Gas Liquid Gas Liquid

1.6~1.8 1.1~1.3

<5.6(19,100) 12.7(1/2) 6.35(1/4) Copper pipe

(0.63~0.71) (0.43~0.51)

1.6~1.8 1.5~1.7 Clamp handle

<16.0(54,600) 15.88(5/8) 9.52(3/8) Red arrow mark

(0.63~0.71) (0.59~0.67)

1.9~2.1 1.5~1.7

<22.4(76,400) 19.05(3/4) 9.52(3/8)

(0.75~0.83) (0.59~0.67)

Firmly hold copper tube in a bar(or die) as indicated

dimension in the table above. Smooth all round

Inside is shining without scratches.

4) Check

■ Compare the flared work with figure right. = Improper flaring =

■ If flare is noted to be defective, cut off the flared section

and do flaring work again.

Inclined Surface Cracked Uneven

damaged thickness

Even length

all round

Installation Manual 17](https://image.slidesharecdn.com/installationmanualmini-130122114709-phpapp02/85/Installation-manual-mini-17-320.jpg)

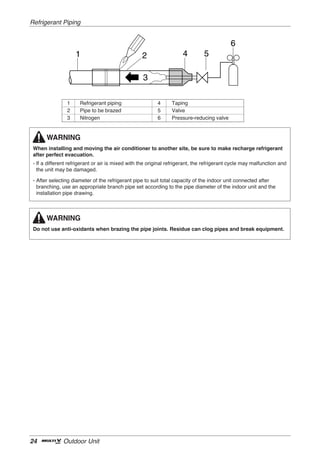

![Refrigerant Piping

Caution

ENGLISH

1. Use the following materials for refrigerant piping.

• Material: Seamless phosphorous deoxidized copper pipe

• Wall thickness : Comply with the relevant local and national regulations for the designed pressure

3.8MPa. We recommend the following table as the minimum wall thickness.

Outer diameter

6.35 9.52 12.7 15.88 19.05 22.2 25.4 28.58 31.8 34.9 38.1 41.3

[mm]

Minimum

0.8 0.8 0.8 0.99 0.99 0.99 0.99 0.99 1.1 1.21 1.35 1.43

thickness [mm]

2. Commercially available piping often contains dust and other materials. Always blow it clean with a dry inert

gas.

3. Use care to prevent dust, water or other contaminants from entering the piping during installation.

4. Reduce the number of bending portions as much as possible, and make bending radius as big as possible.

5. Always use the branch piping set shown below, which are sold separately.

Header

Y branch

4 branch 7 branch 10 branch

ARBLN01621 ARBLN03321 ARBL054 ARBL057 ARBL1010

ARBLN07121 ARBLN14521 ARBL104 ARBL107 ARBL2010

6. If the diameters of the branch piping of the designated refrigerant piping differs, use a pipe cutter to cut

the connecting section and then use an adapter for connecting different diameters to connect the piping.

7. Always observe the restrictions on the refrigerant piping (such as rated length, difference in height, and

piping diameter).

Failure to do so can result in equipment failure or a decline in heating/cooling performance.

8. A second branch cannot be made after a header. (These are shown by .)

A A

B

A To Outdoor Unit

B Sealed Piping

9. The Multi V will stop due to an abnormality like excessive or insufficient refrigerant. At such a time, always

properly charge the unit. When servicing, always check the notes concerning both the piping length and

the amount of additional refrigerant.

10. Never use refrigerant to perform an air purge. Always evacuate using a vacuum pump.

11. Always insulate the piping properly. Insufficient insulation will result in a decline in heating/cooling

performance, drip of condensate and other such problems.

12. When connecting the refrigerant piping, make sure the service valves of the Outdoor Unit is completely

closed (the factory setting) and do not operate it until the refrigerant piping for the Outdoor and Indoor

Units has been connected, a refrigerant leakage test has been performed and the evacuation process

has been completed.

13. Always blow nitrogen into pipe which is brazed. Always use a non-oxidizing brazing material for brazing

the parts and do not use flux. If not, oxidized film can cause clogging or damage to the compressor unit

and flux can harm the copper piping or refrigerant oil.

Installation Manual 23](https://image.slidesharecdn.com/installationmanualmini-130122114709-phpapp02/85/Installation-manual-mini-23-320.jpg)

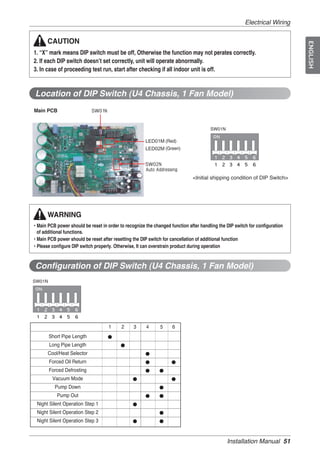

![Refrigerant Piping

Selection of Refrigerant Piping

ENGLISH

Outdoor unit

Gas pipe Liquid pipe

Branching

pipe

Main pipe

Branching Indoor unit

pipe

No. Piping parts Name Selection of pipe size

Size of main pipe

Liquid pipe Gas pipe

Outdoor unit capacity[kW(Btu/h)]

Outdoor unit [mm(inch)] [mm(inch)]

① Main pipe 11.0(37,500) Ø9.52(3/8) Ø15.88(5/8)

↓

1st branching section 14.5(49,500) Ø9.52(3/8) Ø15.88(5/8)

16.0(54,600) Ø9.52(3/8) Ø19.05(3/4)

Pipe size of between branching sections

Liquid pipe Gas pipe

Branching section Indoor unit capacity[kW(Btu/h)]

[mm(inch)] [mm(inch)]

② ↓ Branching pipe

≤ 5.6(19,100) Ø6.35(1/4) Ø12.7(1/2)

Branching section < 16.0(54,600) Ø9.52(3/8) Ø15.88(5/8)

< 22.4(76,400) Ø9.52(3/8) Ø19.05(3/4)

Connecting pipe size of indoor unit

Branching section Liquid pipe Gas pipe

Indoor unit Indoor unit capacity[kW(Btu/h)]

③ ↓

[mm(inch)] [mm(inch)]

connecting pipe

≤ 5.6(19,100) Ø6.35(1/4) Ø12.7(1/2)

Indoor unit

< 16.0(54,600) Ø9.52(3/8) Ø15.88(5/8)

Installation Manual 25](https://image.slidesharecdn.com/installationmanualmini-130122114709-phpapp02/85/Installation-manual-mini-25-320.jpg)

![Refrigerant Piping

■ Combination of Y branch/header method

Example : 5 Indoor Units connected

Ⓐ : Outdoor Unit

Ⓑ : 1st branch (Y branch)

Ⓒ : Y branch

Ⓓ : Indoor Unit

Ⓔ : Header

Ⓕ : Sealed piping

H 50m

L 150m

40m

Branch pipe can not be used after header

➲ Refrigerant pipe diameter from branch to branch (B,C)

Downward Indoor Unit total capacity Liquid pipe Gas pipe

[kW(Btu/h)] [mm(inch)] [mm(inch)]

≤ 5.6(19,100) Ø6.35(1/4) Ø12.7(1/2)

< 16.0(54,600) Ø9.52(3/8) Ø15.88(5/8)

< 22.4(76,400) Ø9.52(3/8) Ø19.05(3/4)

➲ Total pipe length = A+B+C+a+b+c+d+e ≤ 300m

Longest pipe length Equivalent pipe length(*)

L

A+B+b ≤ 150m A+B+b ≤ 175m

Longest pipe length after 1st branch

l

B+b ≤ 40m

Difference in height(Outdoor Unit ↔ Indoor Unit)

H

H ≤ 50m (40m : Outdoor Unit is lower than Indoor Units)

Difference in height (Indoor Unit ↔ Indoor Unit)

h h ≤ 15m

* : Assume equivalent pipe length of Y branch to be 0.5m, that of header to be 1m, calculation purpose

CAUTION

Indoor Unit should be installed at lower position than the header

WARNING

It is recommended that difference of piping length for pipes connected to the Indoor Unit is

minimized. Performance difference between Indoor Units may occur.

28 Outdoor Unit](https://image.slidesharecdn.com/installationmanualmini-130122114709-phpapp02/85/Installation-manual-mini-28-320.jpg)

![Refrigerant Piping

Selection of Y Branch and Header

1. Y Branch

[unit:mm]

Models Gas pipe Liquid pipe

I.D12.7 I.D12.7

I.D15.88 I.D15.88 I.D.6.35 I.D9.52 I.D6.35

I.D9.52

1

I.D15.88 74

ARBLN01621 I.D12.7

I.D.6.35 74

I.D.9.52

281 281

292 292

I.D19.05 1 O.D9.52

O.D15.88

70 I.D12.7 70

I.D22.2 I.D19.05 I.D15.88 I.D19.05 I.D12.7

2 I.D12.7

1

I.D9.52 I.D9.52 I.D6.35

I.D19.05

I.D25.4 83

I.D15.88 I.D12.7

ARBLN03321 390 I.D12.7

I.D12.7

74

3 I.D9.52 I.D6.35

413

O.D19.05 I.D22.2 I.D28.58 O.D25.4

O.D19.05

I.D22.2 321

I.D25.4 332

3 1 2

70 80 110

I.D19.05 I.D19.05

I.D28.58 I.D22.2 I.D15.88 I.D12.7 I.D15.88 I.D15.88 I.D12.7

2 2

1

I.D12.7

I.D15.88 I.D19.05 I.D15.88 I.D19.05 83

I.D31.8 96

I.D19.05 I.D12.7

ARBLN07121

376 371 3

3

404 394

I.D28.58 I.D31.8 I.D34.9 O.D31.8 O.D19.05 I.D22.2 O.D12.7 I.D9.52 I.D6.35 O.D12.7 I.D9.52

I.D28.58

2 1 3 3 2

O.D22.2

120 90 120 110 70

I.D34.9

I.D41.3 I.D38.1 I.D28.58 I.D19.05

2 I.D15.88 I.D19.05 I.D22.2 I.D15.88

I.D34.9 2

1

I.D38.1 I.D28.58 I.D15.88

125 I.D22.2 I.D19.05 I.D12.7

I.D34.9 I.D22.2 96

471

ARBLN14521 3

416 3

517

444

I.D19.05 I.D15.88 O.D38.1 I.D41.3 O.D34.9 I.D38.1

3

2 3 I.D41.3

O.D22.2 I.D12.7 O.D19.05 I.D9.52

120 130 O.D15.88 I.D9.52 I.D22.2 O.D12.7 I.D6.35

90

I.D12.7 O.D28.58 I.D22.2 2 3 3

3

2 I.D19.05

O.D15.88 110 80 110

For example. Indicated Ø9.52 is the outer diameter(O.D..) of field jointed piping

34 Outdoor Unit](https://image.slidesharecdn.com/installationmanualmini-130122114709-phpapp02/85/Installation-manual-mini-34-320.jpg)

![Refrigerant Piping

ENGLISH

2. Header

[unit:mm]

Models Gas pipe Liquid pipe

360 360

120 120

ID12.7 ID6.35

ID12.7 ID6.35

4 branch

ID15.88 150 ID9.52 150

ARBL054 ID15.88 120 ID9.52 120

ID19.05 ID15.88 ID12.7 ID9.52

540 540

120 120

ID12.7 ID6.35

7 branch ID12.7

ID15.88 150 ID9.52

ARBL057 ID15.88 120 120 150

ID19.05 ID15.88

ID12.7 ID9.52

400 360

160 120

ID15.88 ID6.35

ID12.7 ID6.35

4 branch ID9.52

ID19.05 150 150

ID15.88 120 ID9.52 120

ARBL104

ID28.58 ID25.4 ID22.2 ID12.7 ID9.52

700

580

160 120

ID15.88 ID6.35

7 branch ID12.7 ID6.35

ID19.05 150 ID9.52 150

ARBL107 ID15.88 120 ID9.52 120

ID28.58 ID25.4 ID22.2

ID12.7 ID9.52

760 720

160

ID15.88

120

ID12.7 ID6.35

ID6.35

10 branch ID19.05 150

ID15.88 120 150

ARBL1010 ID9.52 120

ID28.58 ID25.4 ID22.2

ID9.52

ID12.7 ID9.52

700

775

182 60*9=540 107

ID15.88 ID6.35

10 branch ID12.7 ID6.35

ID19.05 150 150

ARBL2010 ID15.88 120 ID9.52 120

ID9.52 ID15.88 ID19.05

ID31.8 ID34.9 ID28.58

Installation Manual 35](https://image.slidesharecdn.com/installationmanualmini-130122114709-phpapp02/85/Installation-manual-mini-35-320.jpg)

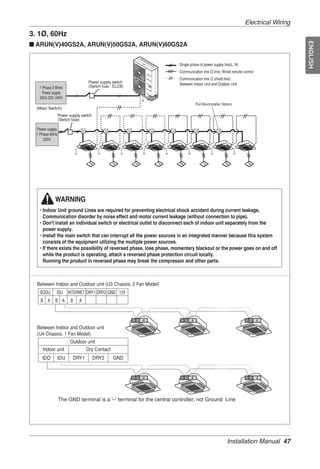

![Electrical Wiring

■ Example Connection of Communication Cable

ENGLISH

[BUS type]

• Connection of communication cable must be installed like below figure between indoor unit to outdoor

unit.

[STAR type]

• Abnormal operation can be caused by communication defect, when connection of communication

cable is installed like below figure(STAR type).

Installation Manual 49](https://image.slidesharecdn.com/installationmanualmini-130122114709-phpapp02/85/Installation-manual-mini-49-320.jpg)

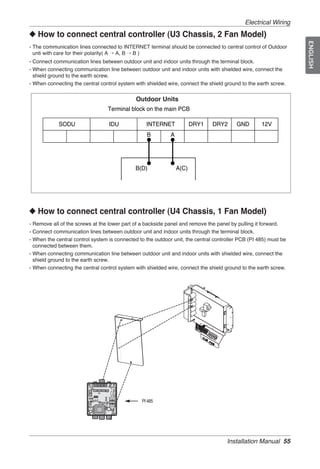

![Test Run

CAUTION

1. Guaranteed Temperature range(Error occurs out of guaranteed temperature range)

IDU : 20~32°C

ODU : 10~38°C

2. Set IDU wired remote controller temperature sensor setting as 'IDU'.

3. Make certain that IDU doesn't run with thermo off mode during operation.

[ Error contents about auto refrigerant charging function ]

1. : Temperature Range Error (In case that IDU or ODU is out of range)

2. : System Unstable Error (In case, After 45 min operating the system, it does not be stable)

How to cope with Result of Refrigerant Checking

1. If the temperature is not in guaranteed Temperature range, the system will not execute Refrigerant

checking and the system will be OFF.

2. Excess of Refrigerant(619)

After remove the 20% of calculated total refrigerant, recharge the refrigerant by using Refrigerant Auto

Charging Function.

3. Scarcity of Refrigerant(629)

Charge the refrigerant by using Refrigerant Auto Charging Function.

4. Impossible to Judge(639)

IF the system is not in order, check the other problem except refrigerant.

64 Outdoor Unit](https://image.slidesharecdn.com/installationmanualmini-130122114709-phpapp02/85/Installation-manual-mini-64-320.jpg)