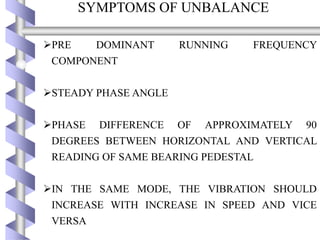

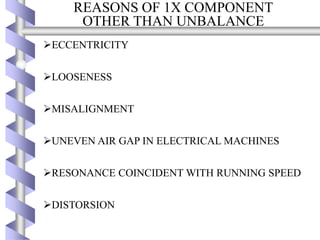

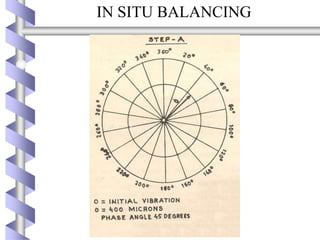

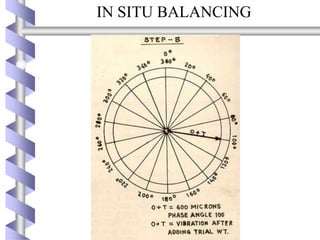

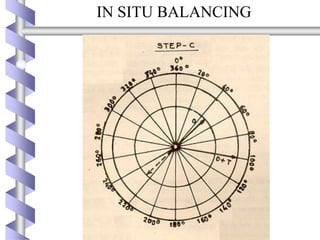

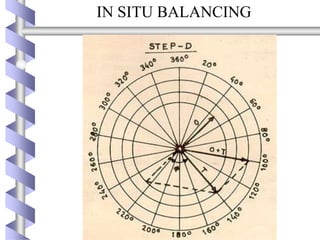

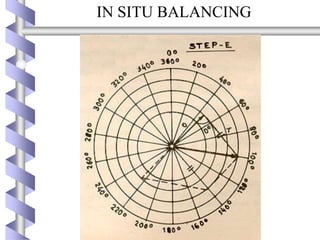

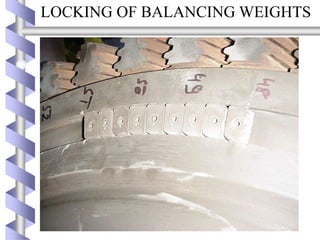

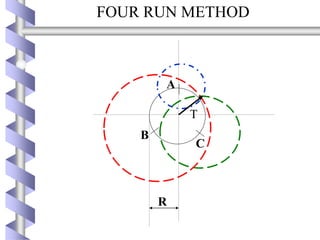

This document discusses the methodology of in situ balancing of rotating machinery. It describes different types of unbalance, causes of unbalance, symptoms of unbalance, and reasons a machine may exhibit a 1x vibration component other than unbalance. The methodology of in situ balancing is explained in multiple steps, including measuring initial vibration, adding a trial weight, measuring vibration with trial weight, removing weight and constructing a vector diagram to determine the correction weight and position. Methods for locking balancing weights are also summarized, as well as an alternative four run balancing method. Reasons why balancing may not resolve vibrations are provided.