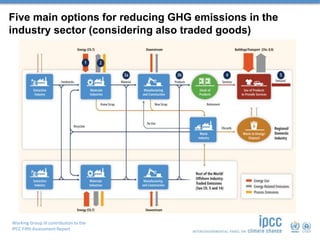

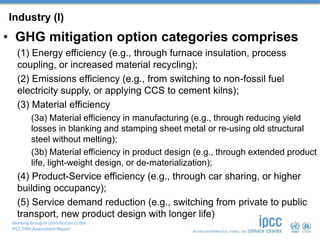

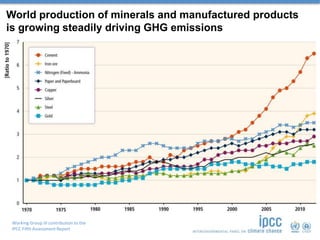

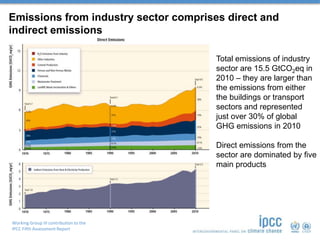

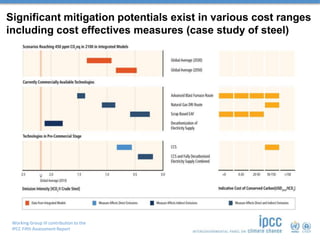

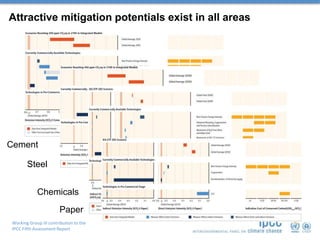

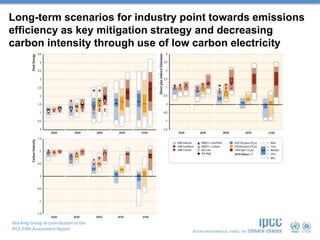

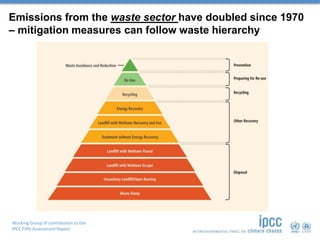

The document discusses greenhouse gas (GHG) emission mitigation options for the industry sector. It identifies five main categories of options: energy efficiency, emissions efficiency, material efficiency in manufacturing and product design, product-service efficiency, and service demand reduction. Direct emissions from industry are dominated by five main products. Significant mitigation potential exists through cost-effective efficiency measures and innovation. Long-term, emissions efficiency through low-carbon electricity and technologies like carbon capture and storage could significantly reduce industry's absolute GHG emissions. Waste reduction, reuse, recycling and energy recovery also offer mitigation strategies.