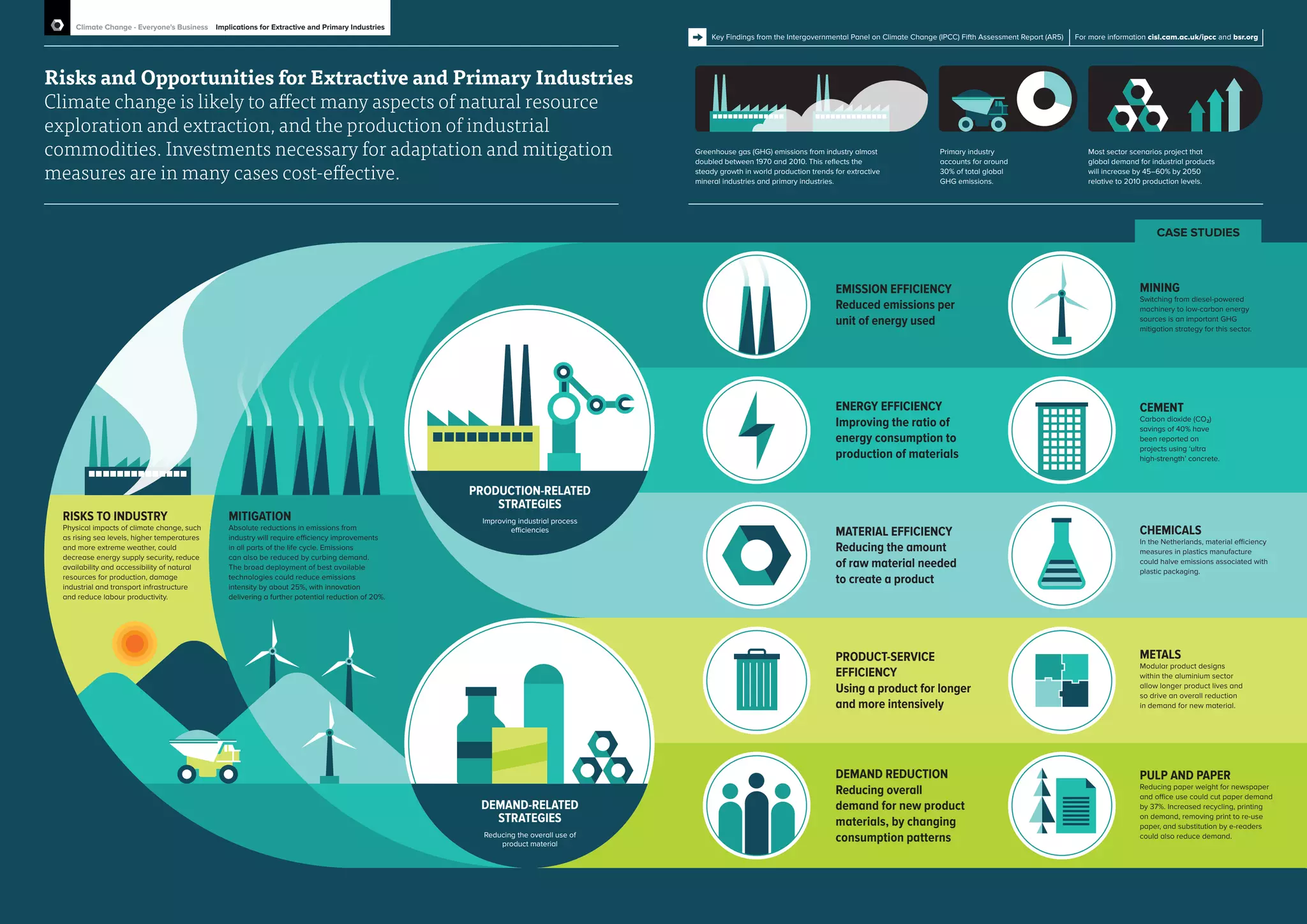

The document discusses the implications of climate change for extractive and primary industries based on the IPCC's fifth assessment report. It highlights the significant contribution of these industries to global greenhouse gas emissions and outlines various strategies for mitigation, including efficiency improvements and changes in consumption patterns. Additionally, it points to the risks posed by climate change to energy security and resource access in industrial production.