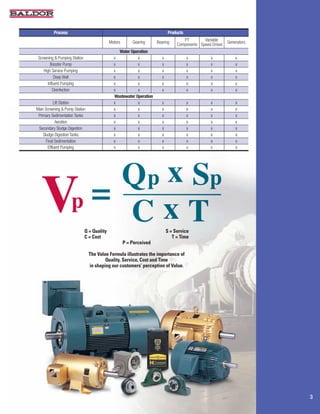

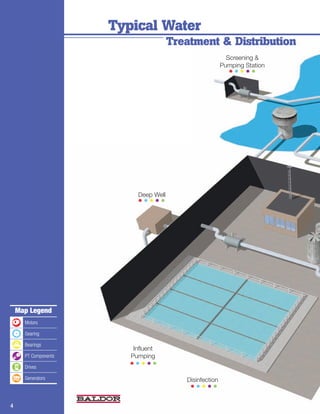

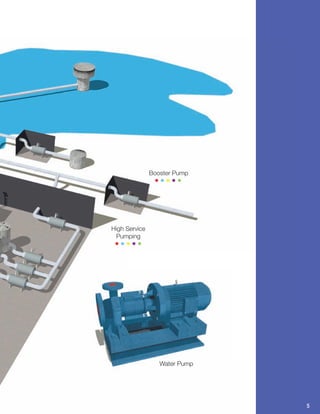

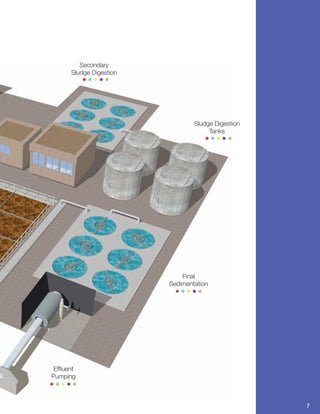

This document discusses products and solutions from Baldor for the water/wastewater industry. It outlines the challenges facing the industry, including increased demand, costs, and regulations. Baldor offers a range of electrical and mechanical products like motors, gearing products, bearings, and variable speed drives to help improve efficiency and performance in water and wastewater operations. Baldor provides engineering support and industry expertise to help customers optimize their systems and lower costs.