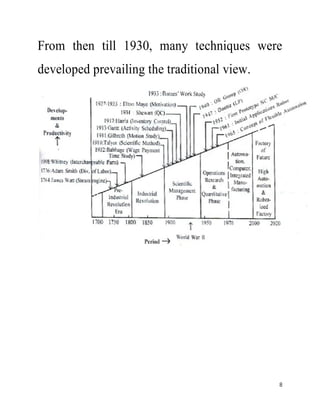

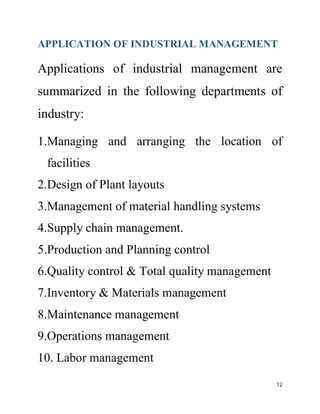

The document discusses the evolution and scope of industrial management, highlighting its importance in enhancing organizational efficiency and productivity since the industrial revolution. It outlines the principles and functions of industrial management, including planning, organizing, and controlling resources to add value to products and services. The benefits of effective industrial management impact consumers, investors, employees, suppliers, and communities by driving economic growth and stability.