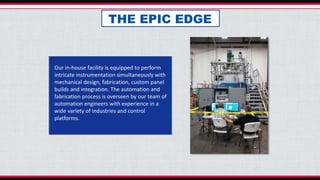

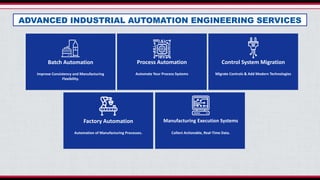

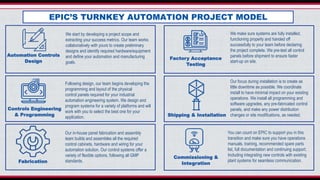

Epic Systems, founded in 1995, specializes in industrial automation engineering, offering comprehensive services from design to commissioning for manufacturing systems. The company emphasizes a turnkey approach to automation, ensuring reduced risk and increased efficiency through in-house fabrication and integration capabilities. Epic's focus on ethics and collaboration allows for tailored solutions that enhance consistency and flexibility in manufacturing processes.