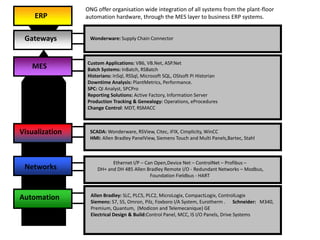

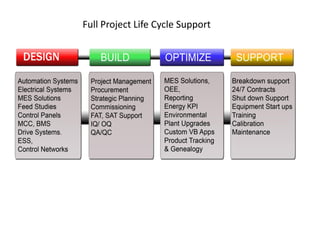

ONG was established in 1993 and is headquartered in Cork, Ireland with offices in Doha, Qatar and Florida, USA. They are a worldwide solution provider of industrial automation and MES systems, accredited to ISO 9000 and GAMP 5. ONG has over 20 years of experience integrating systems from manufacturers including Wonderware, Rockwell, and Siemens across industries like food and beverage, pharmaceuticals, manufacturing, and semiconductors. They provide full project life cycle support including custom applications, historians, production tracking, ERP integration, training, and maintenance services.