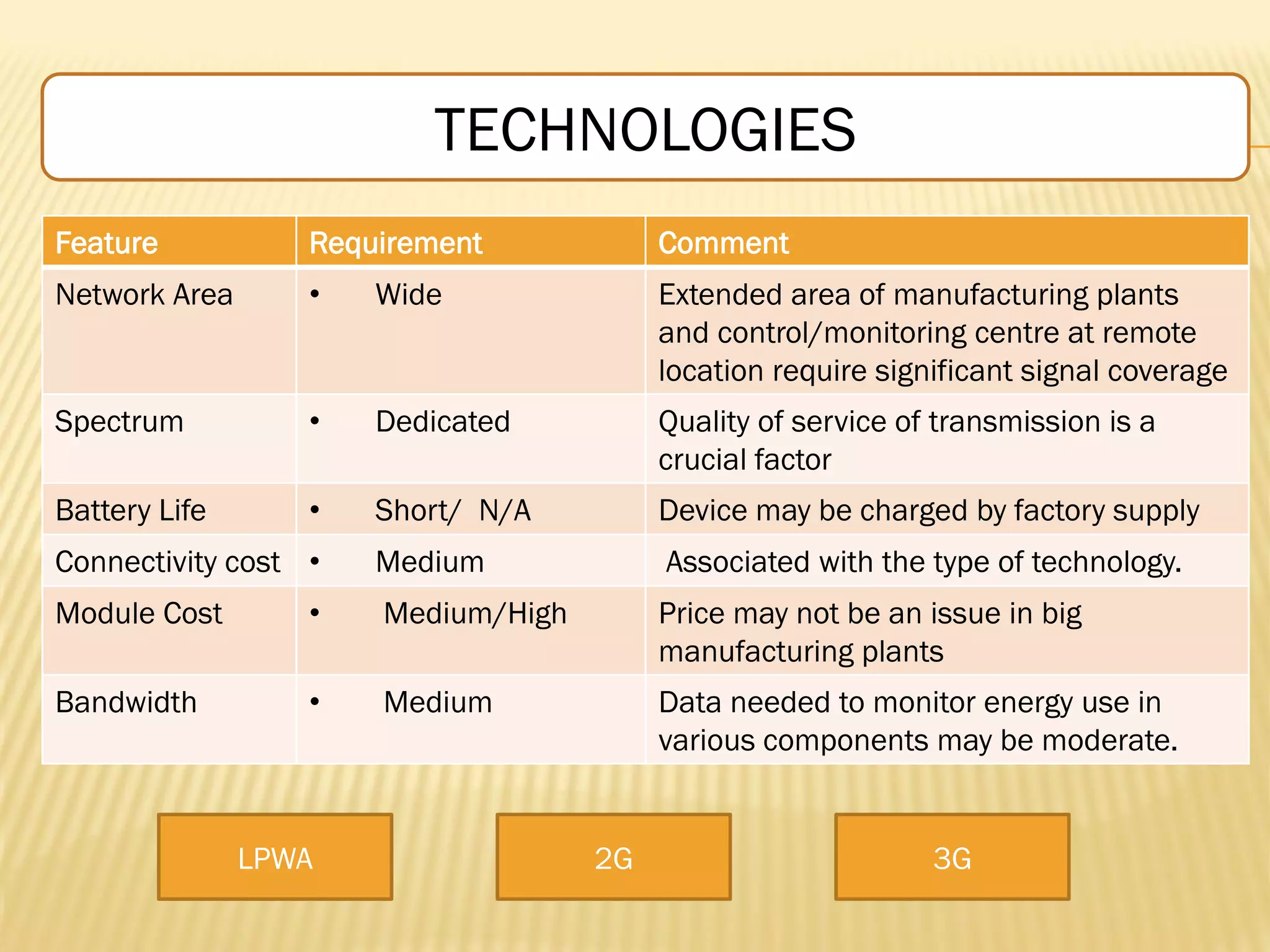

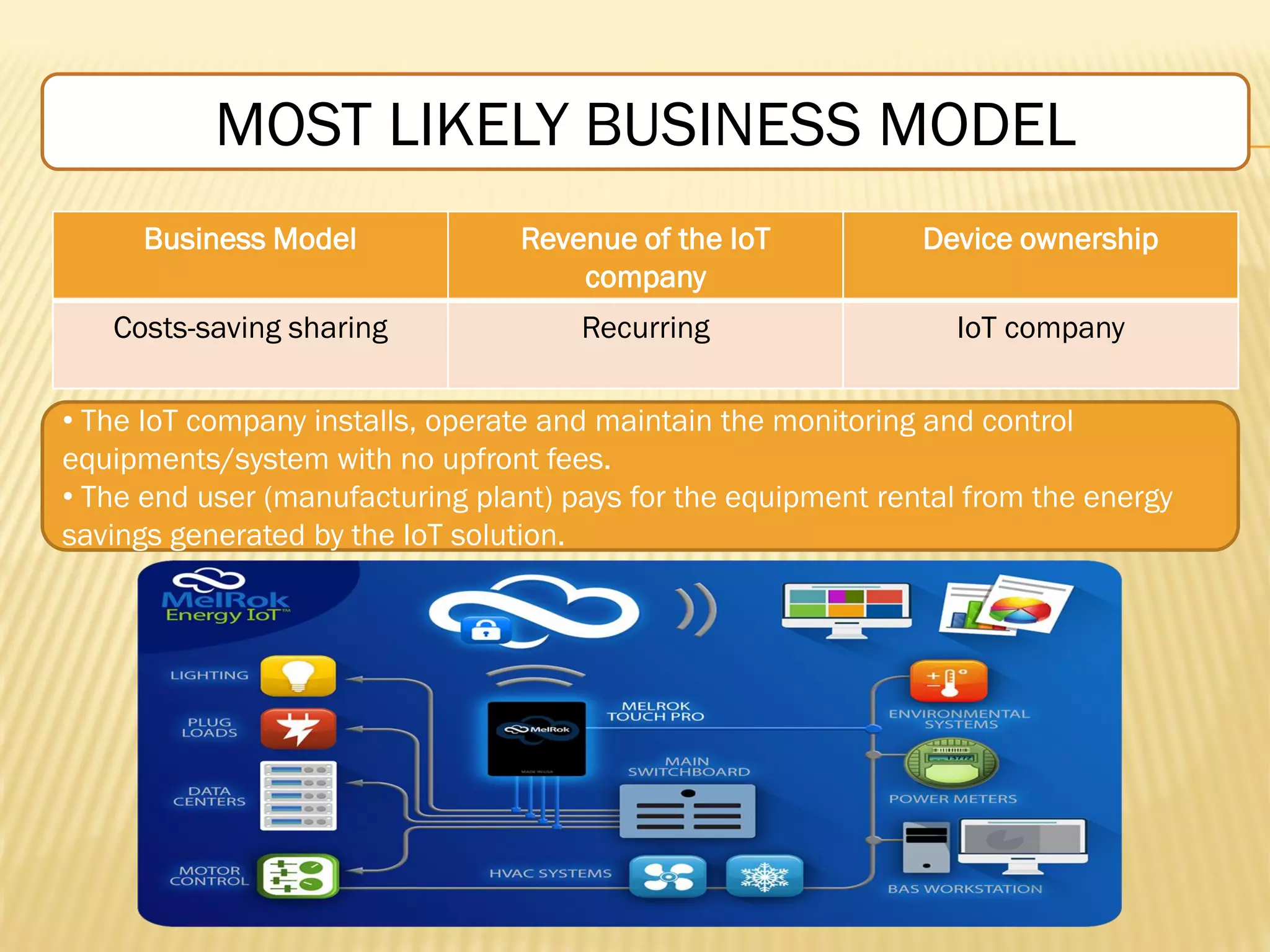

The document discusses the application of IoT to enhance operational efficiency in manufacturing plants, focusing on energy management. It highlights how IoT enables granular monitoring of energy consumption at the device level, allowing for predictive maintenance, optimized production schedules, and reduced energy waste. These advancements lead to increased operational efficiency and profitability by minimizing downtime and energy expenses.