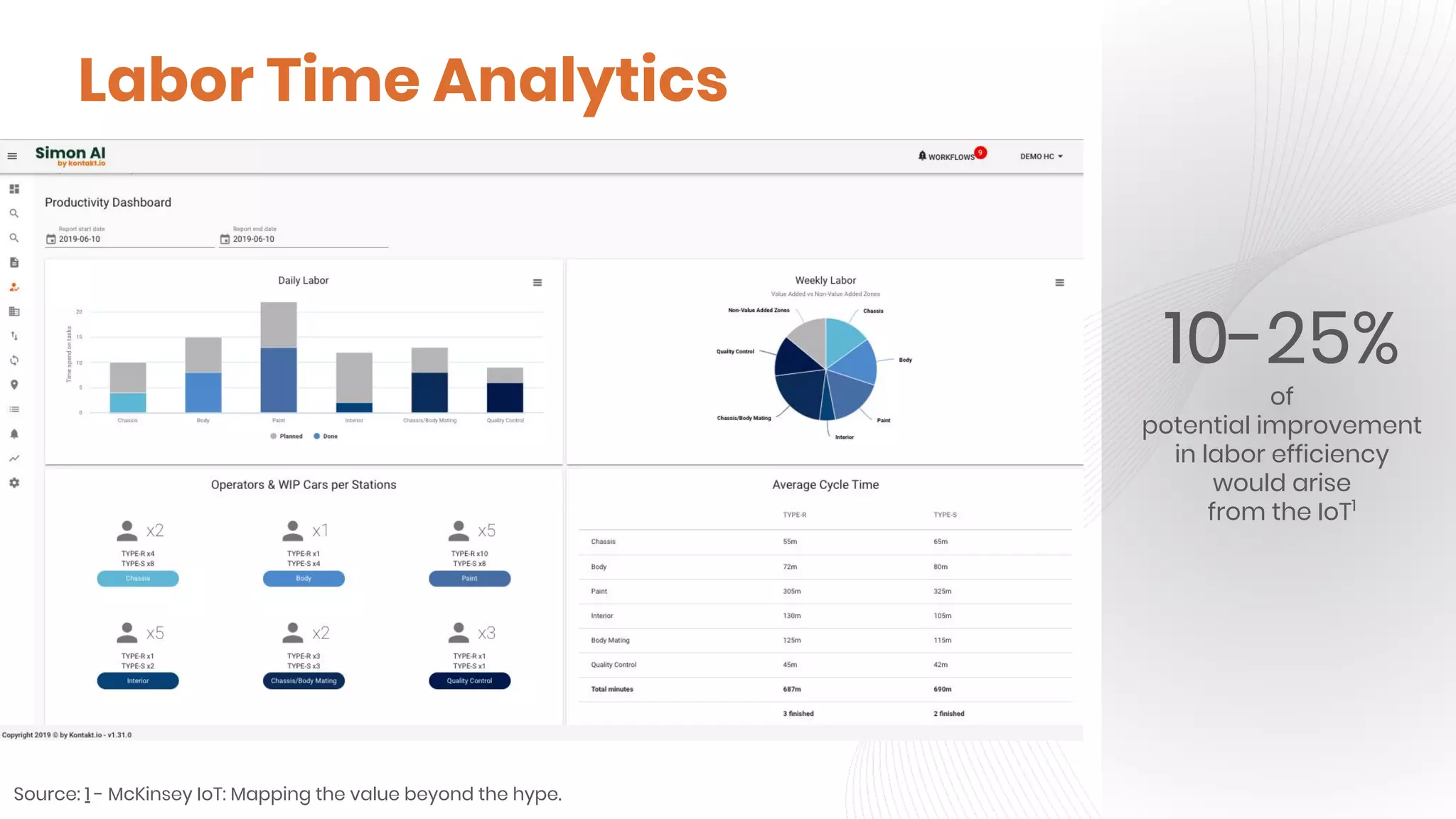

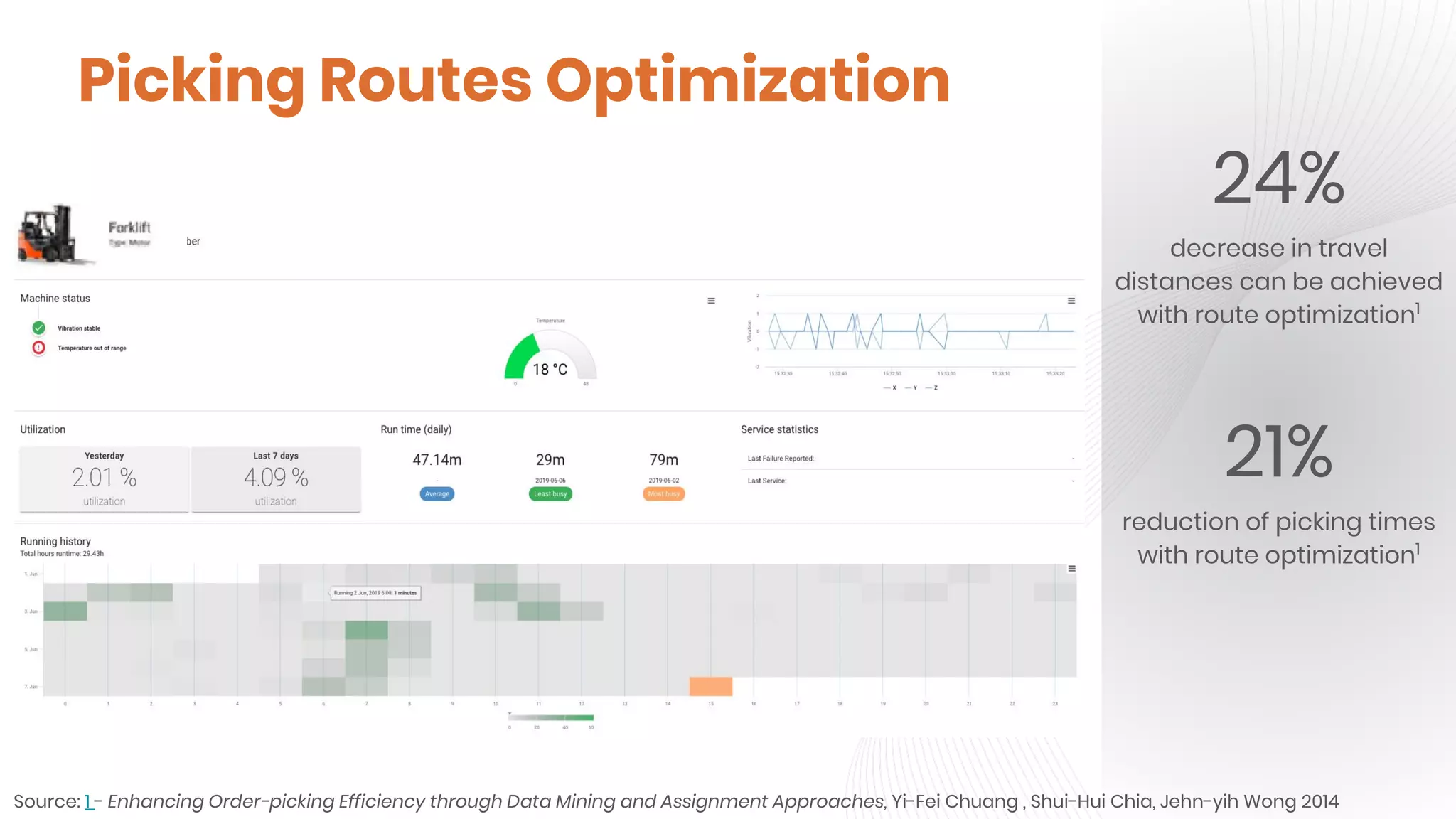

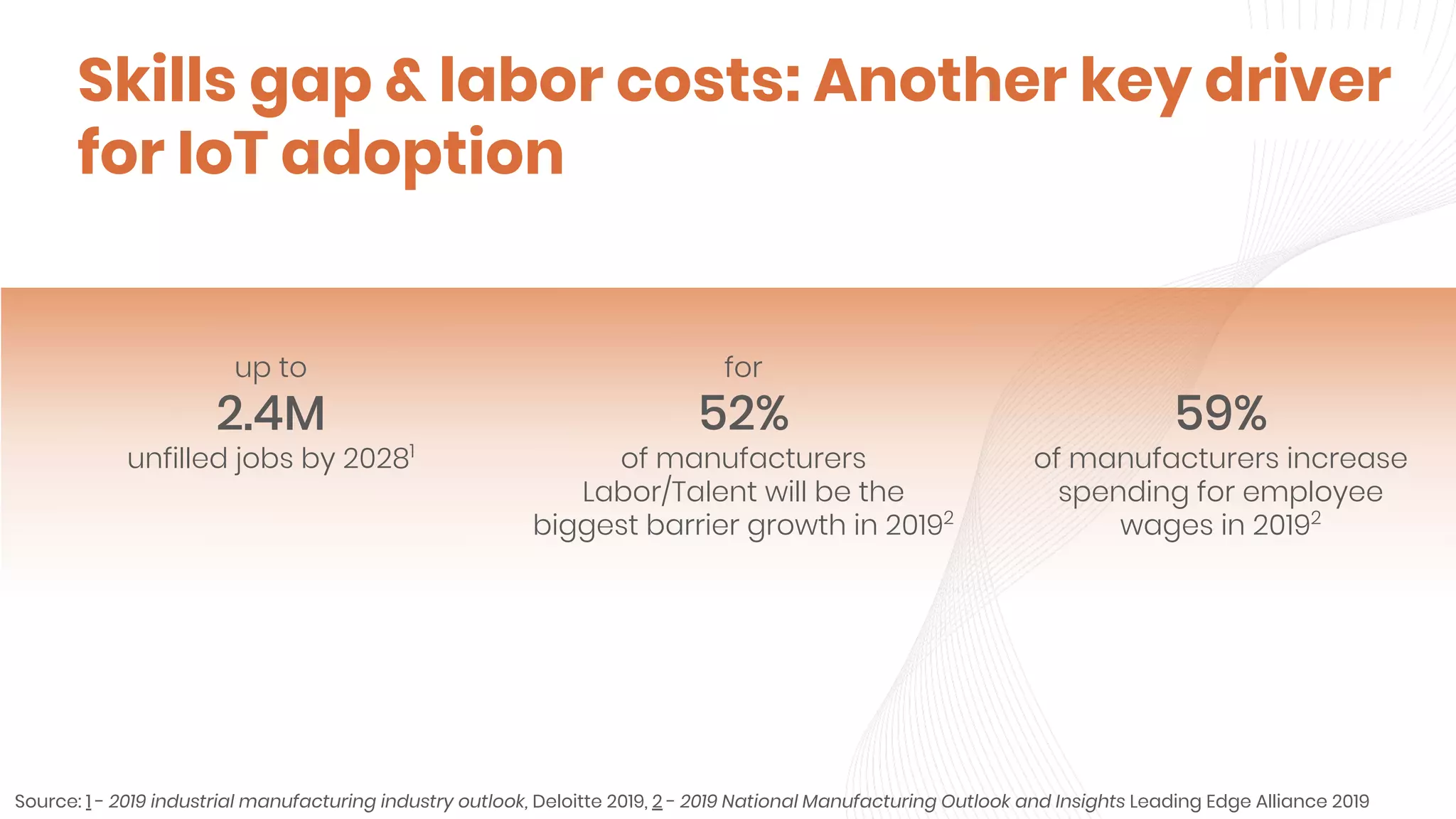

The document discusses the growing importance of IoT in manufacturing, highlighting key trends and statistics such as 82% of manufacturers planning digital transformation to enhance efficiency and profitability. It addresses the challenges within the manufacturing space, emphasizing the need for digitization and outlining various IoT use cases that can lead to significant cost reductions and operational improvements. Additionally, it introduces 'Simon,' an operational experience platform designed to enhance productivity by integrating sensor and location data.

![IoT helps eliminate waste and hence

inefficiencies

Source: Manufacturing - a sector study The performance of manufacturing companies within Benchmark Index, Business Link [2] 2015, K2, 3 - ITIC 2016,

>50%

of manufacturers

say that too much

time is spent

on managing

processes2

30%

of stock

is made up

of finished

product1

83%

of global manufacturers

place operational

complexity among their

top concerns2

~$100,000

costs a single hour of

downtime3](https://image.slidesharecdn.com/iotinmanufacturingwebinar-190614111633/75/Webinar-IoT-in-Manufacturing-6-2048.jpg)