The document discusses how IoT can be applied in manufacturing. It describes how IoT enables digital/connected factories through remote monitoring and management of machinery. IoT sensors also allow for condition-based maintenance alerts and facility management. Production flow, inventory, plant safety and security, quality control, packaging, and logistics can all be optimized through IoT applications in manufacturing. The advantages include asset tracking, predictive maintenance, and process monitoring, while the disadvantages include security risks, high costs, and potential connectivity issues.

![1.ABSTRACTION

The Internet of Things (IoT) envisions the seamless interconnection of

the physical world and the cyber space. This provides a promising

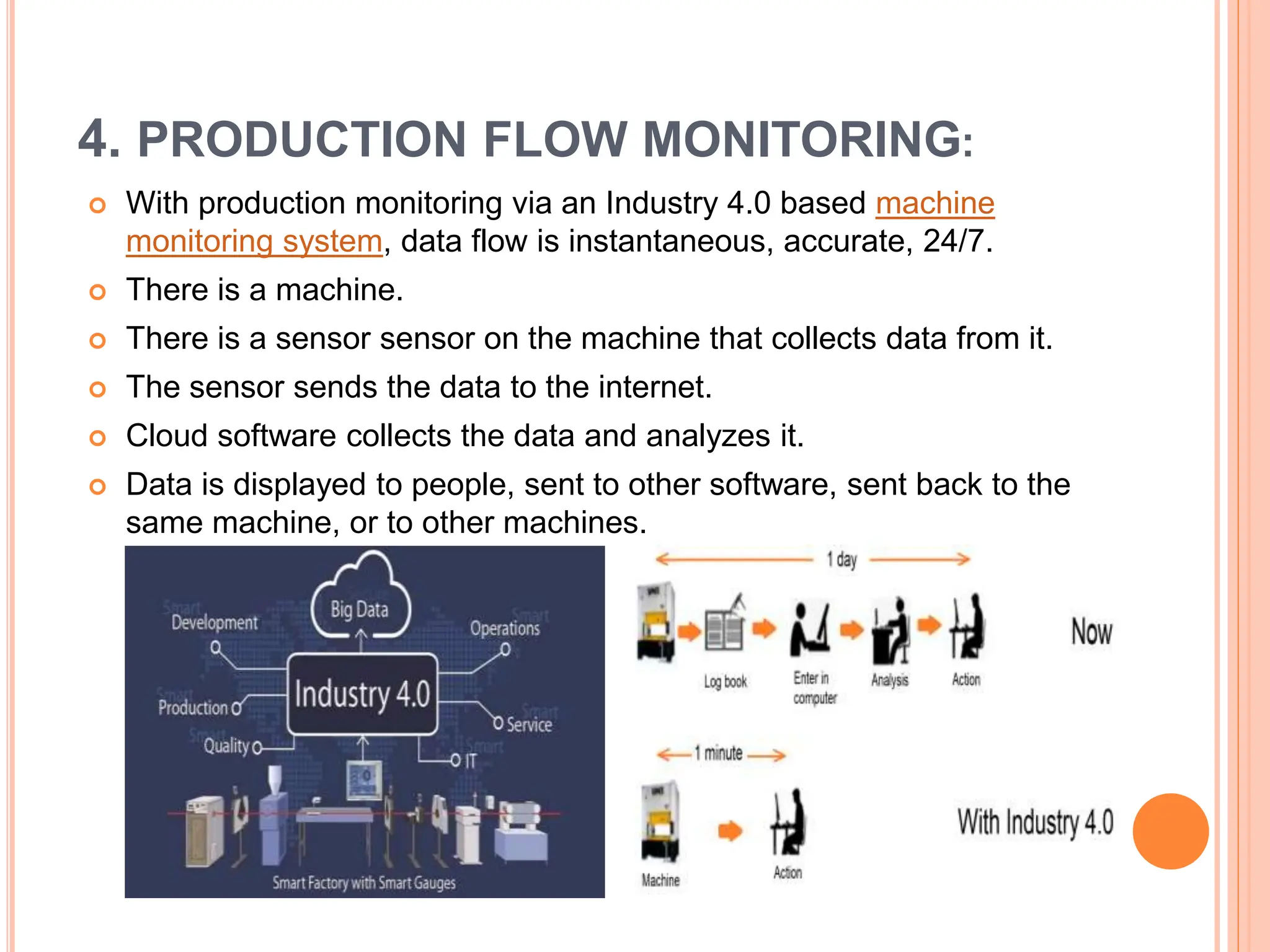

opportunity to build powerful services and applications for manufacturing.

2.INTRODUCTION:

With the globalization of the world’s economy, manufacturing

enterprises are facing severe competition from their worldwide

counterparts in terms of product price, function, quality, cost, lead-

time, etc. and growing pressure to meet higher environmental

standards due to the “enhanced producer responsibility” [1].

Meanwhile, consumers have more diversified and demanding needs,

e.g., customized products. These challenges push the manufacturing

industry to embrace new technologies to keep competitive and meet

user demands. The Internet of Things (IoT), which has great potential

in transforming the manufacturing sector [2], attracts tremendous

attention from both academia and industry.](https://image.slidesharecdn.com/iotapplicationinmanufacturing-231216083334-4e80530a/75/IoT-Application-in-Manufacturing-Advantage-Disadvantage-2-2048.jpg)