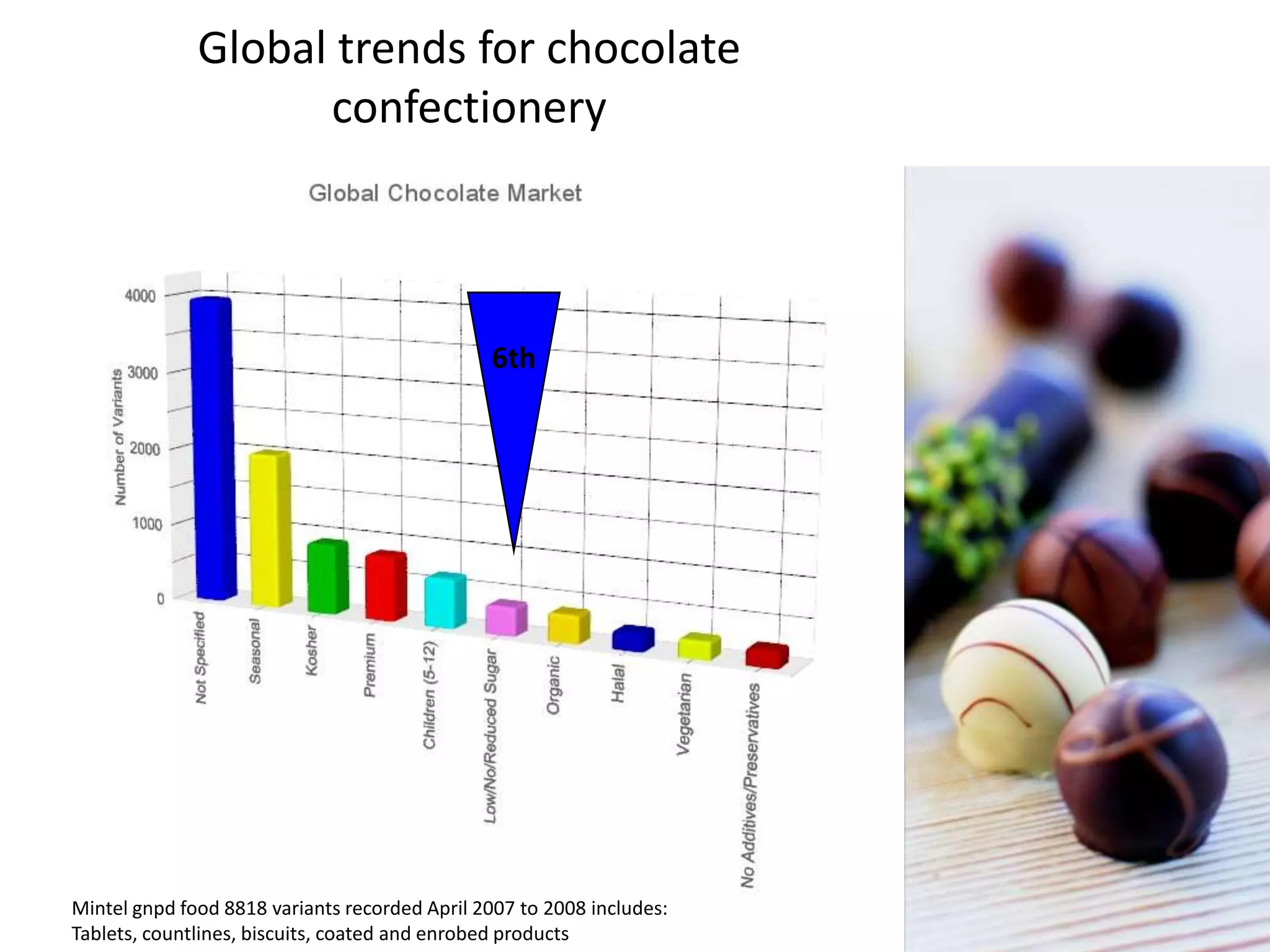

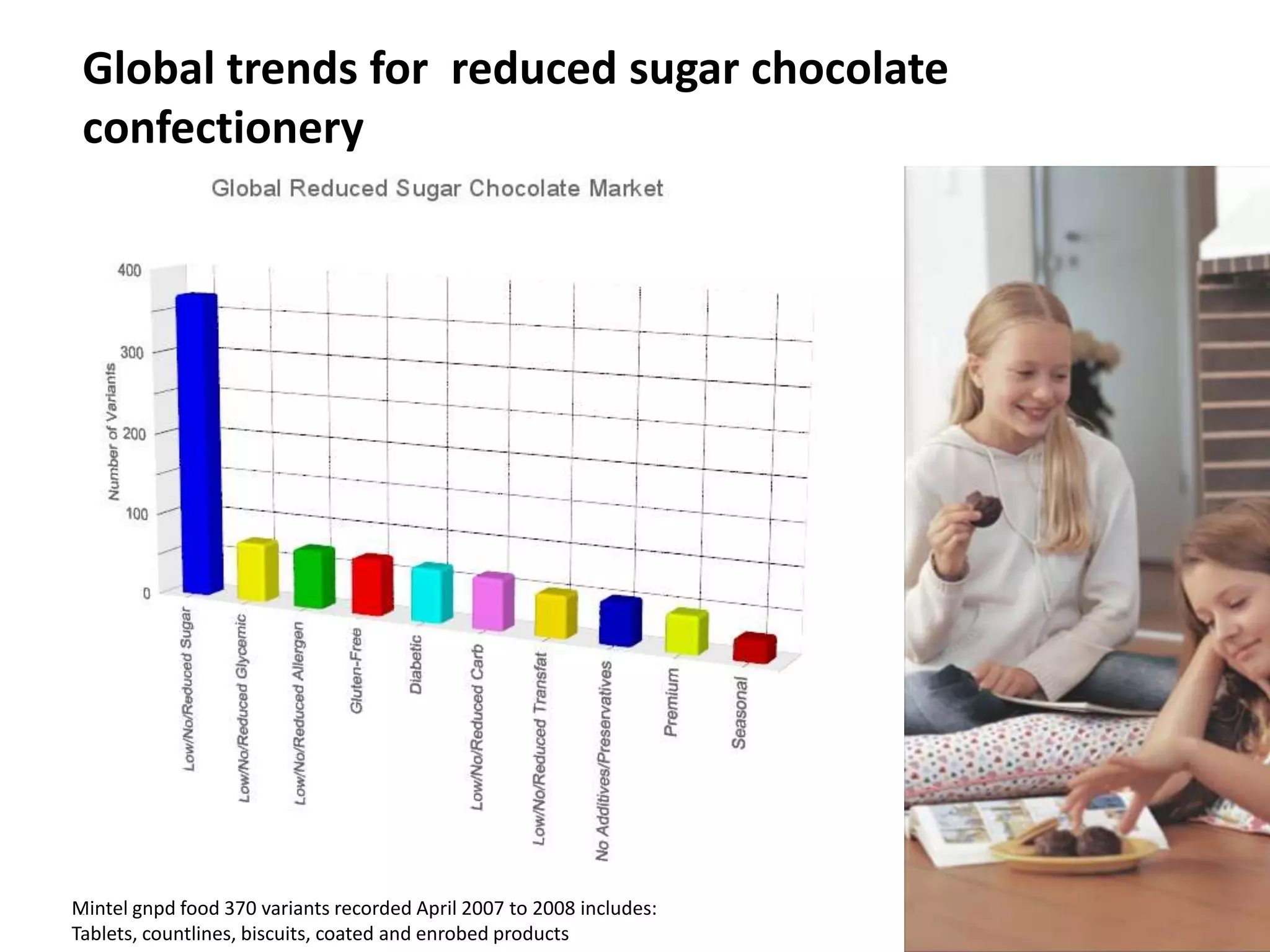

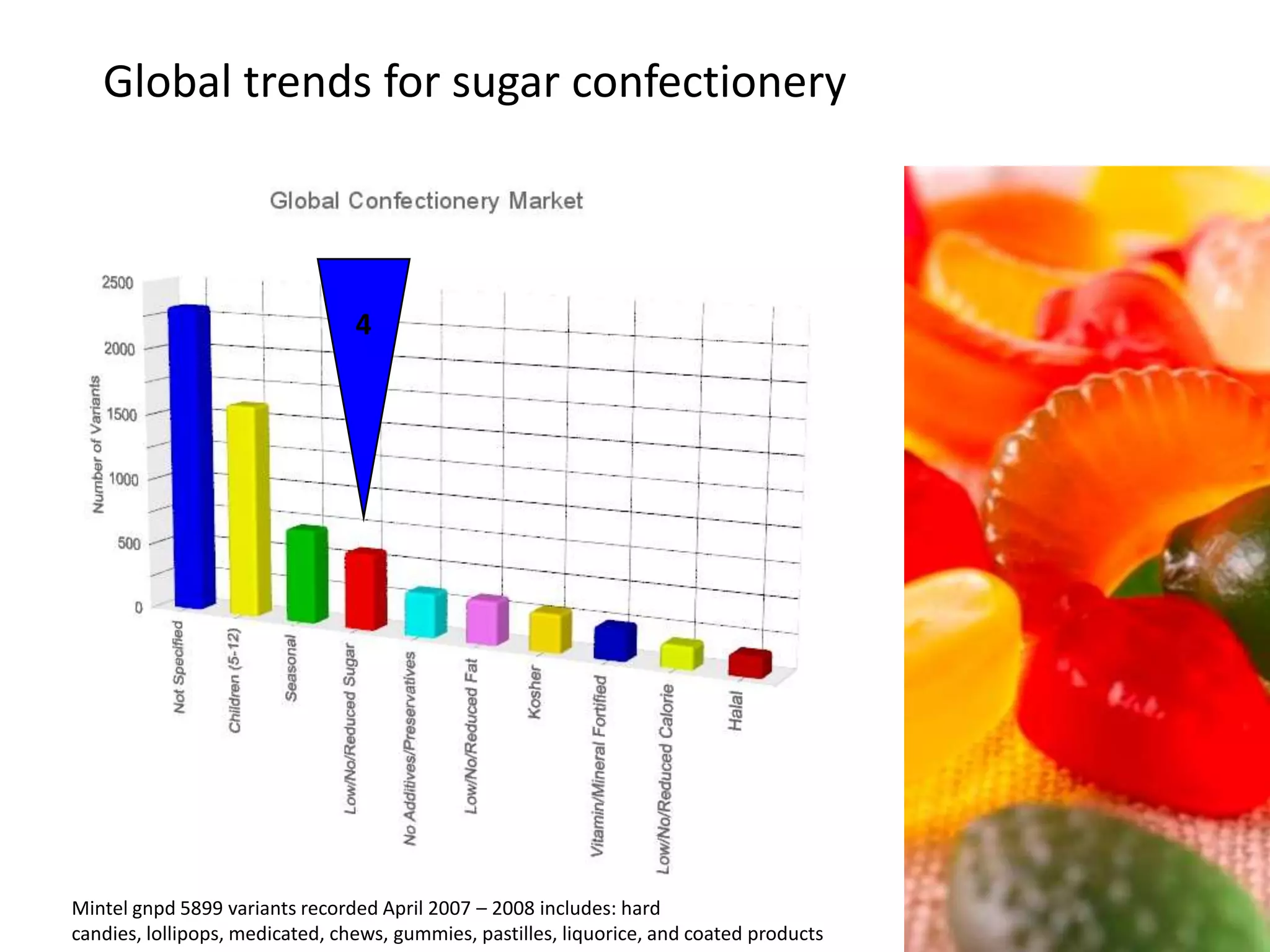

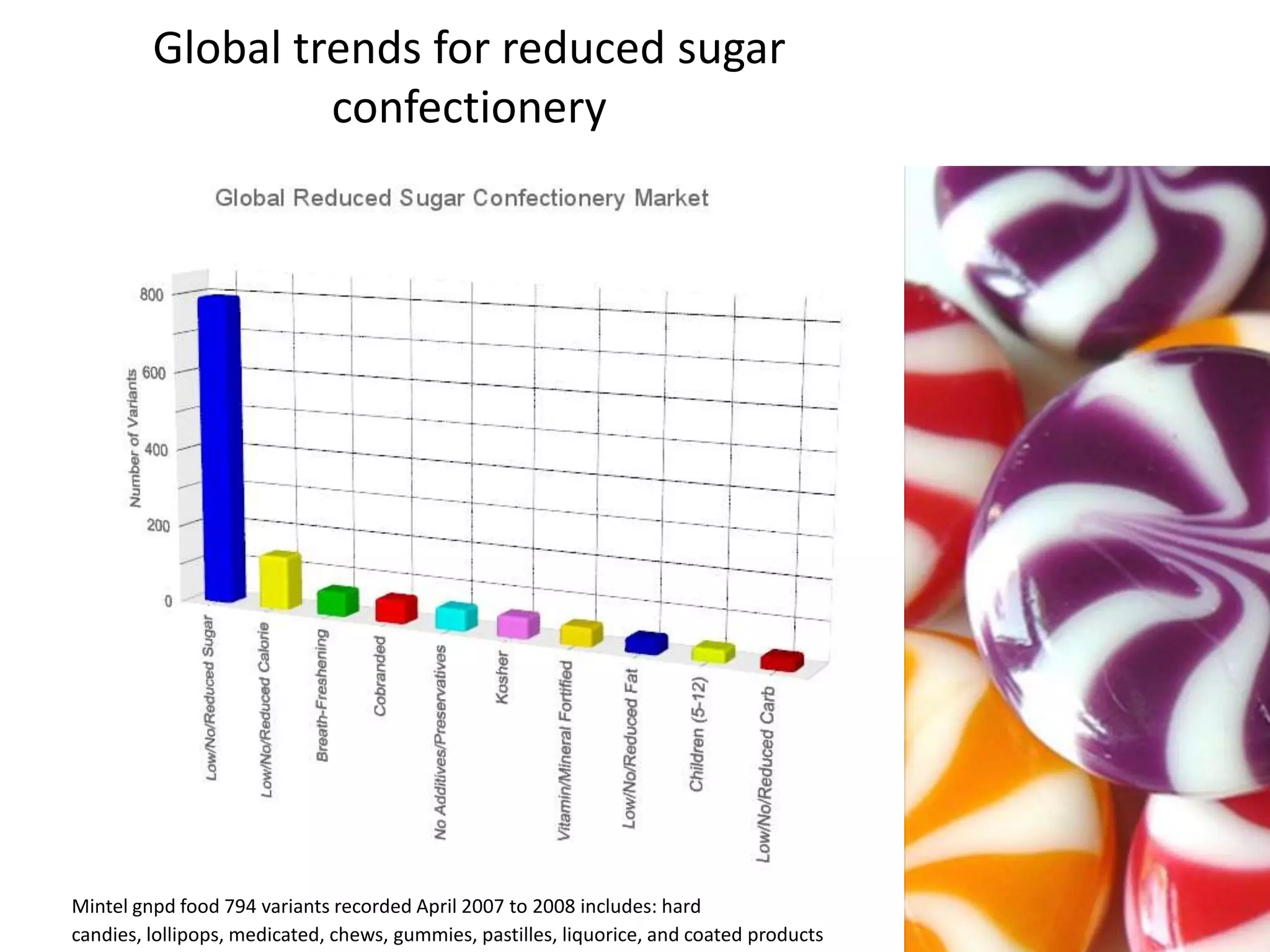

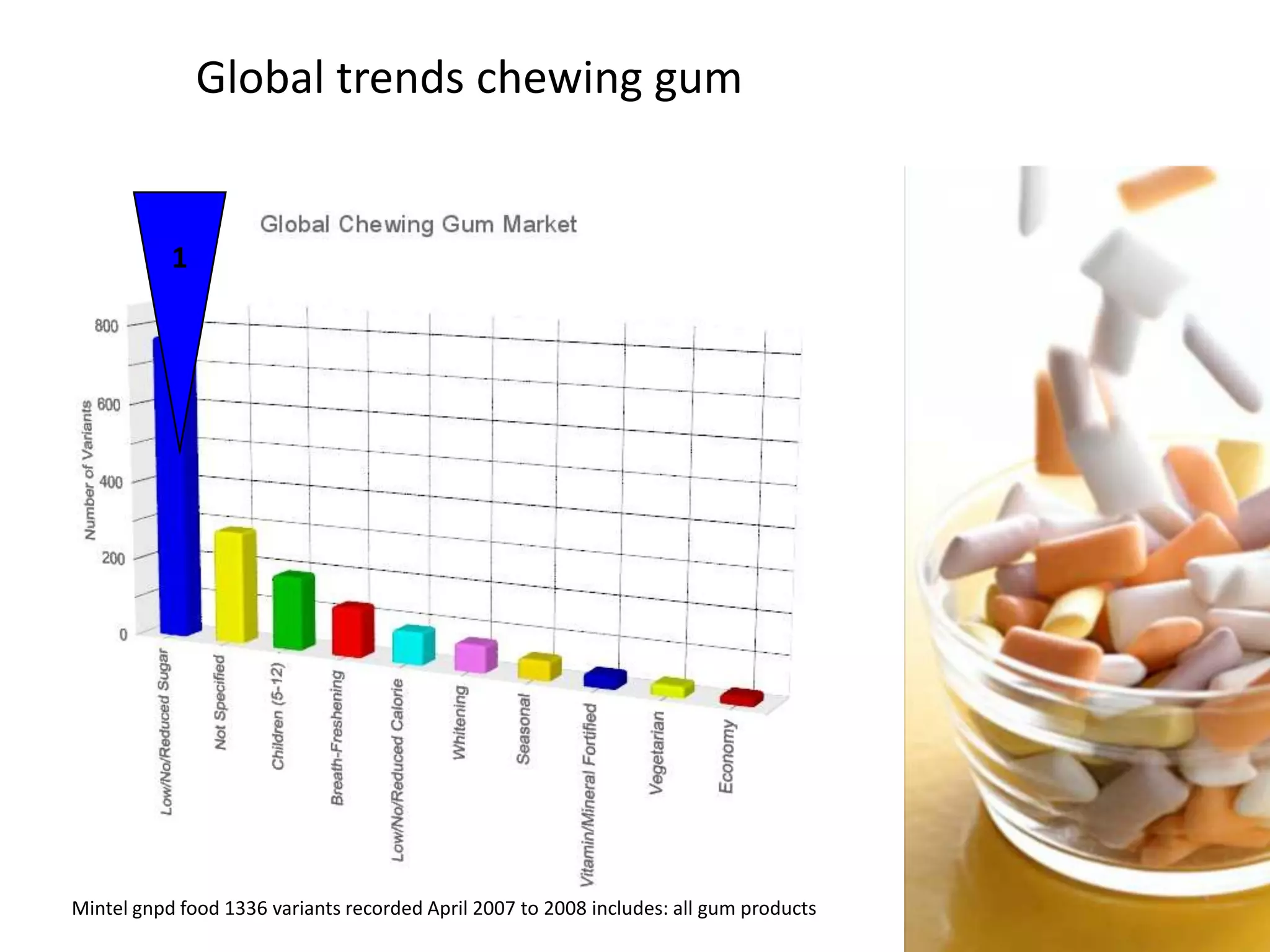

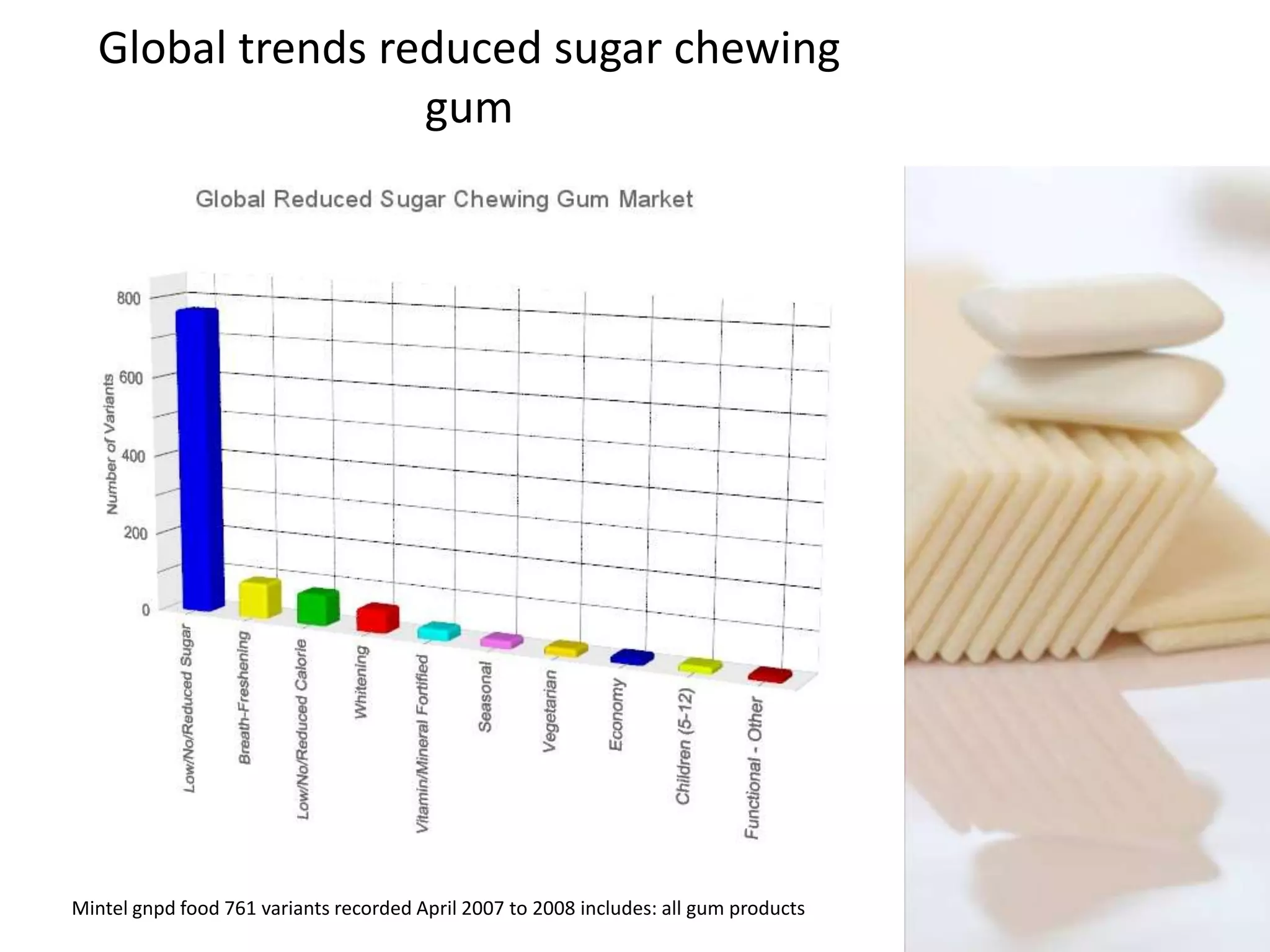

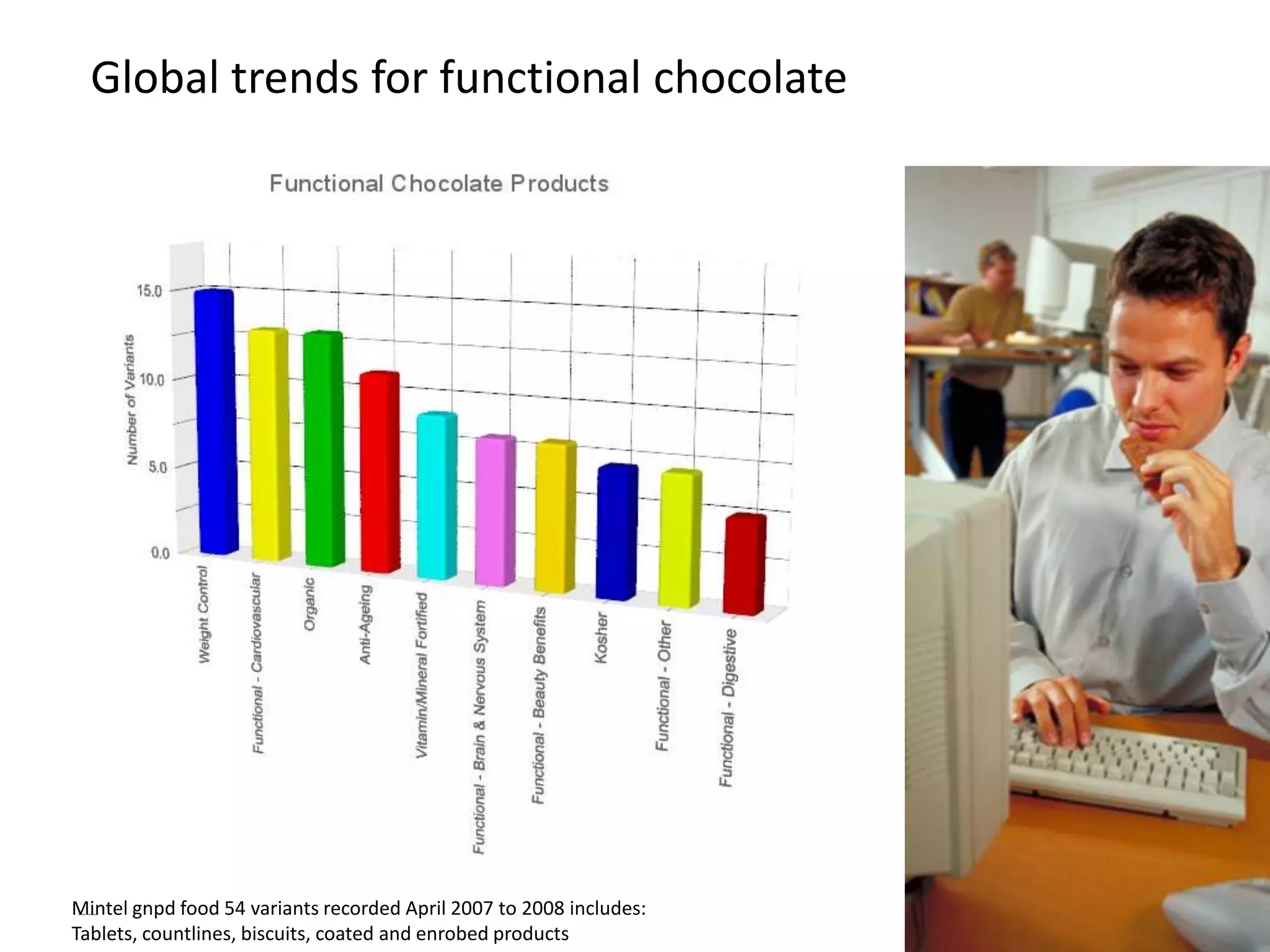

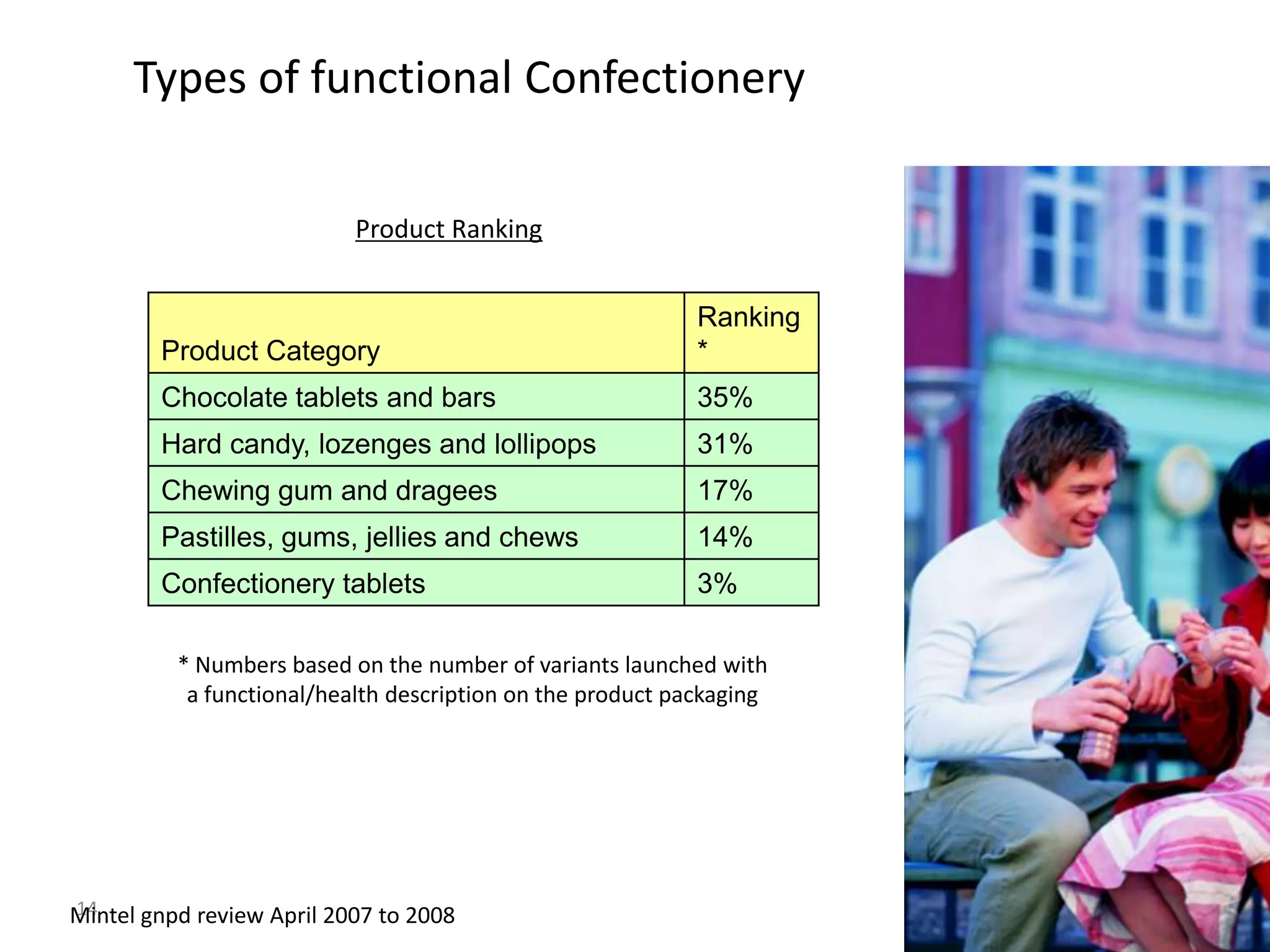

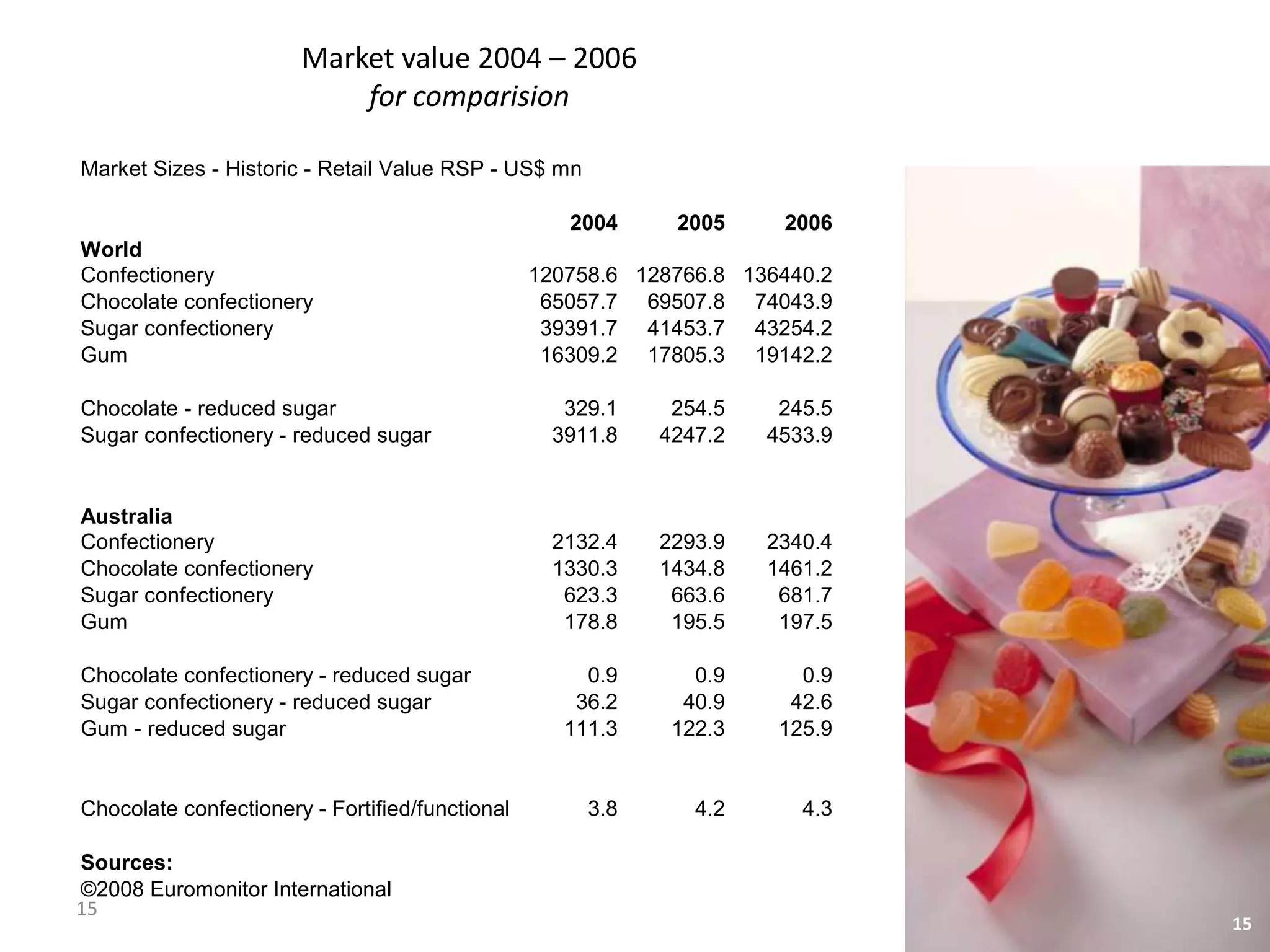

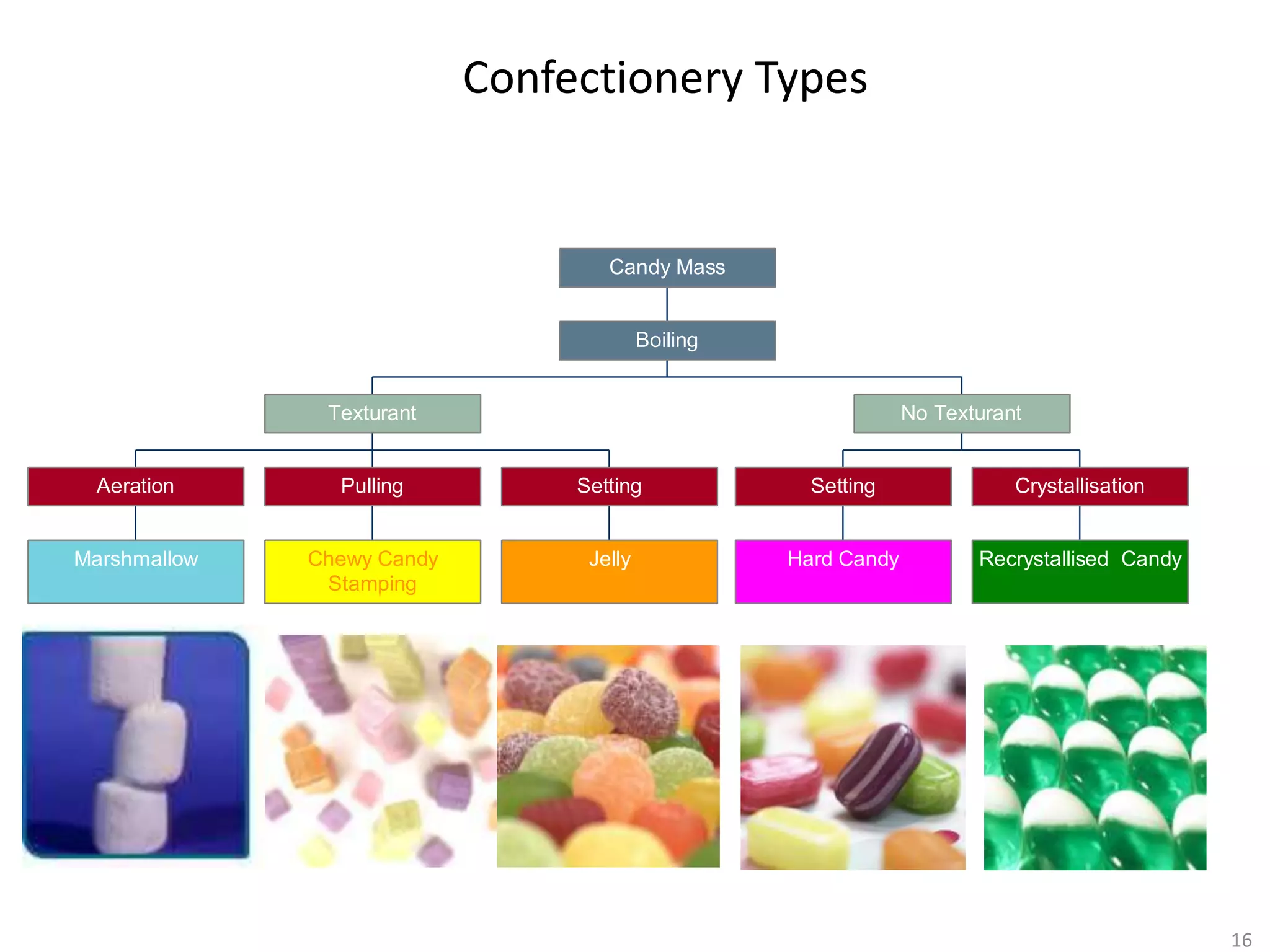

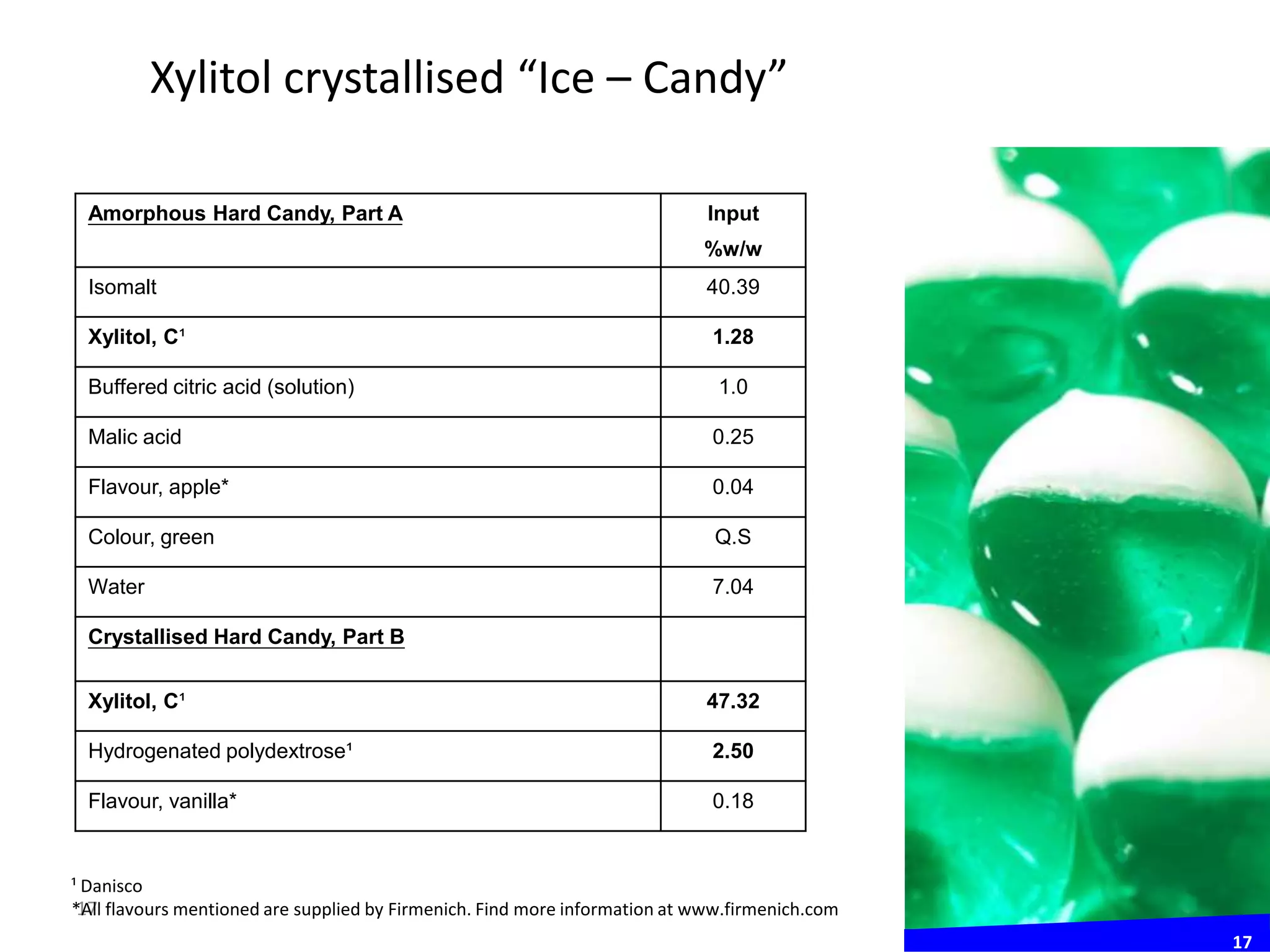

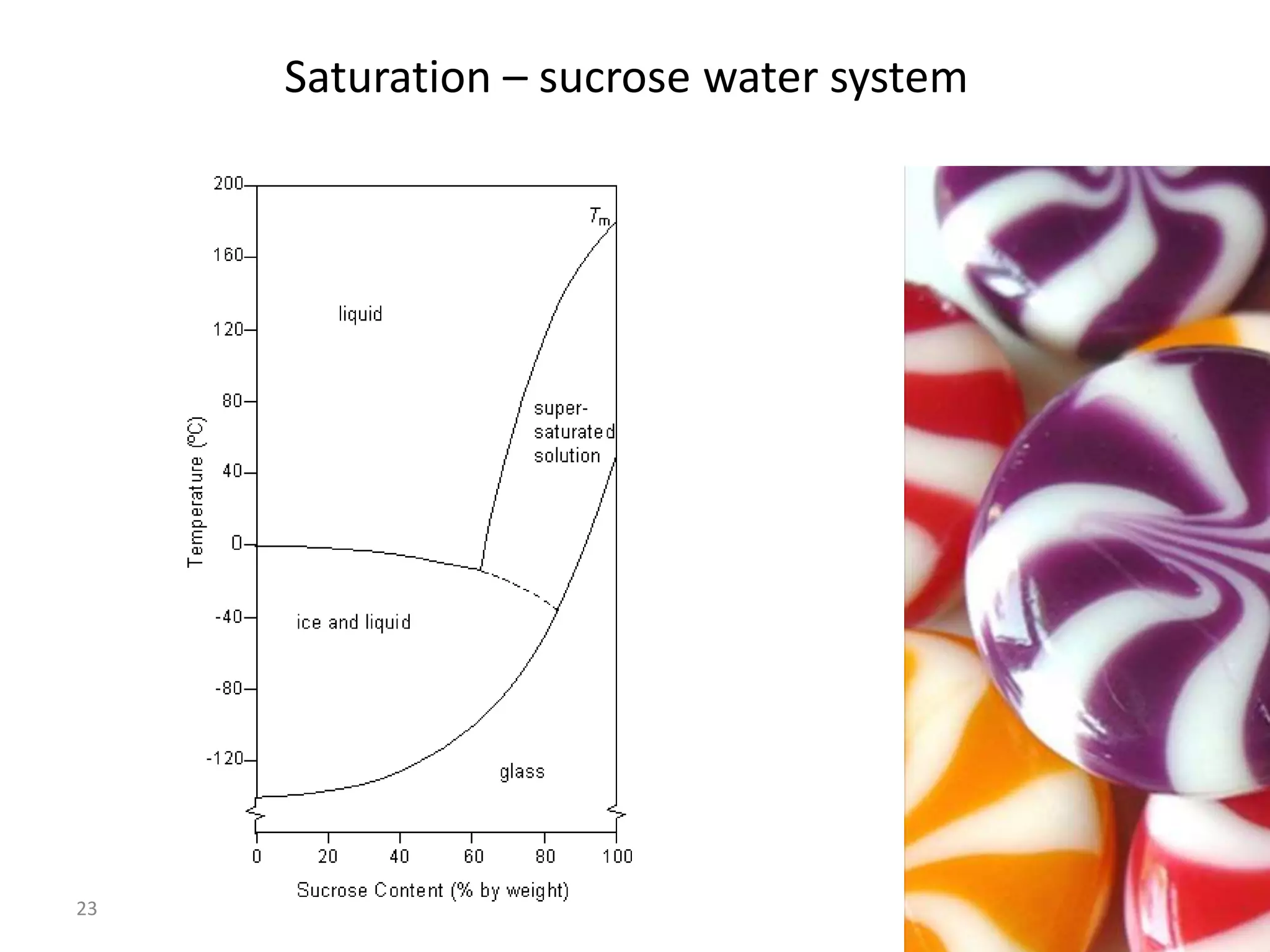

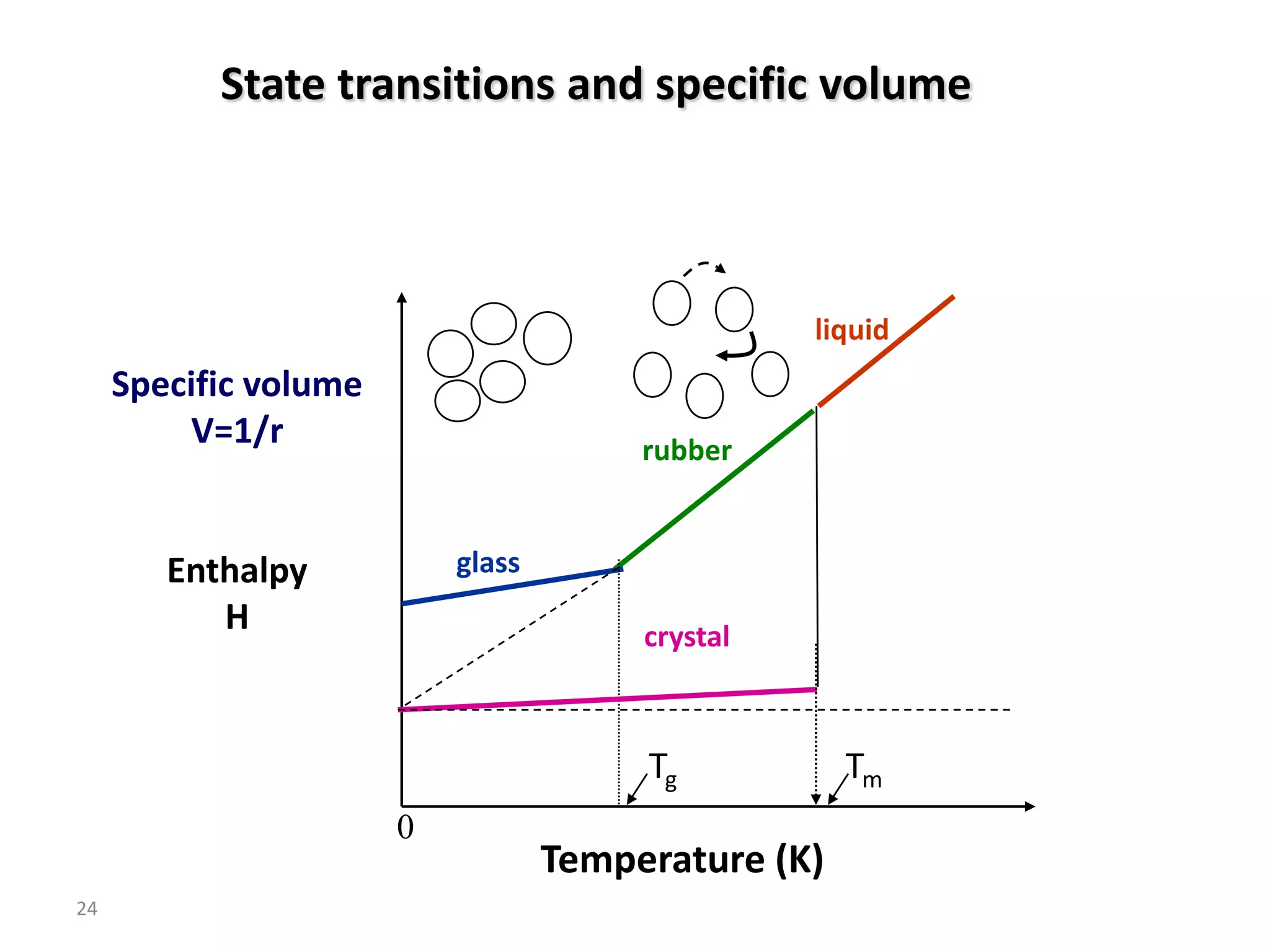

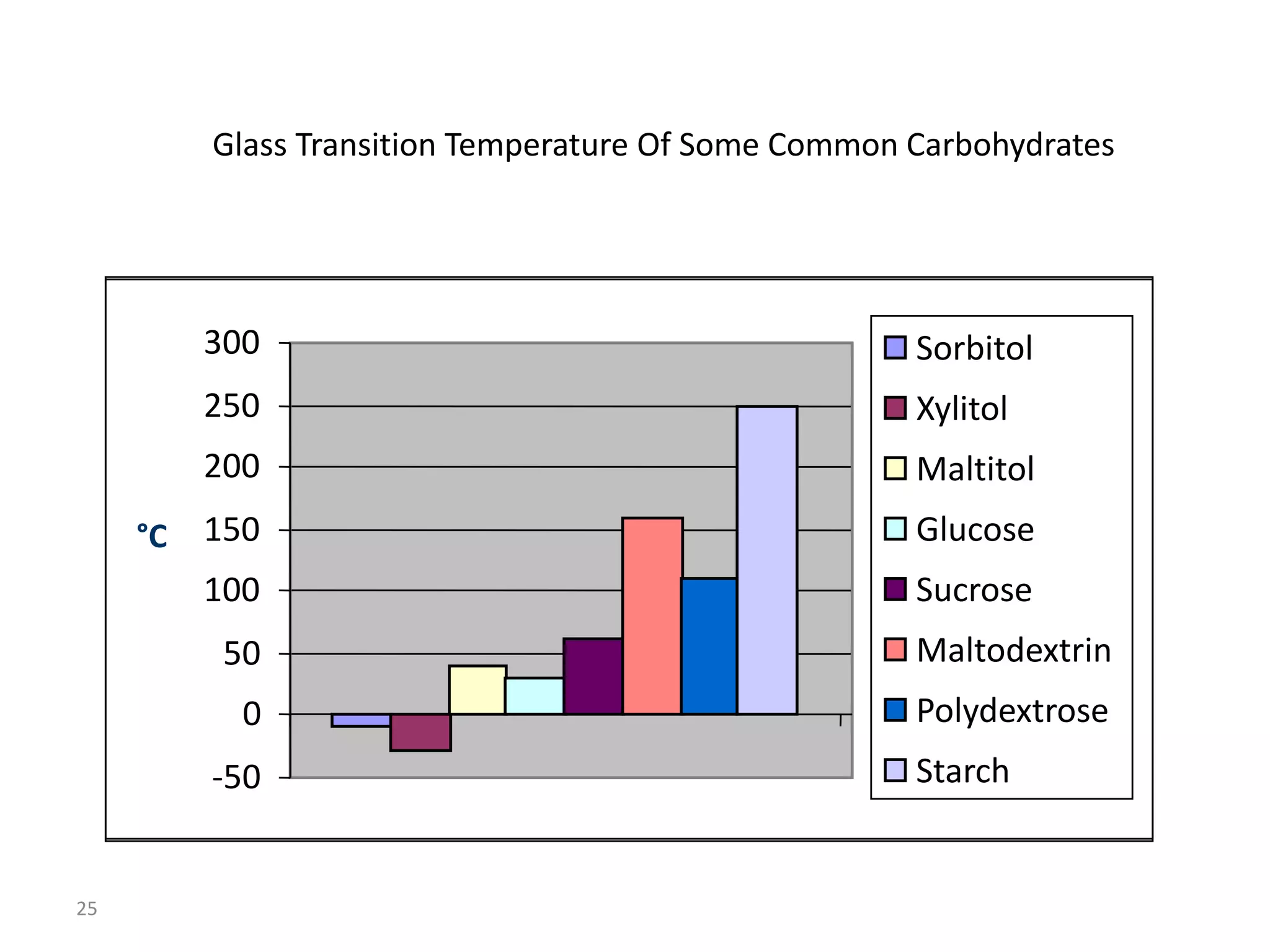

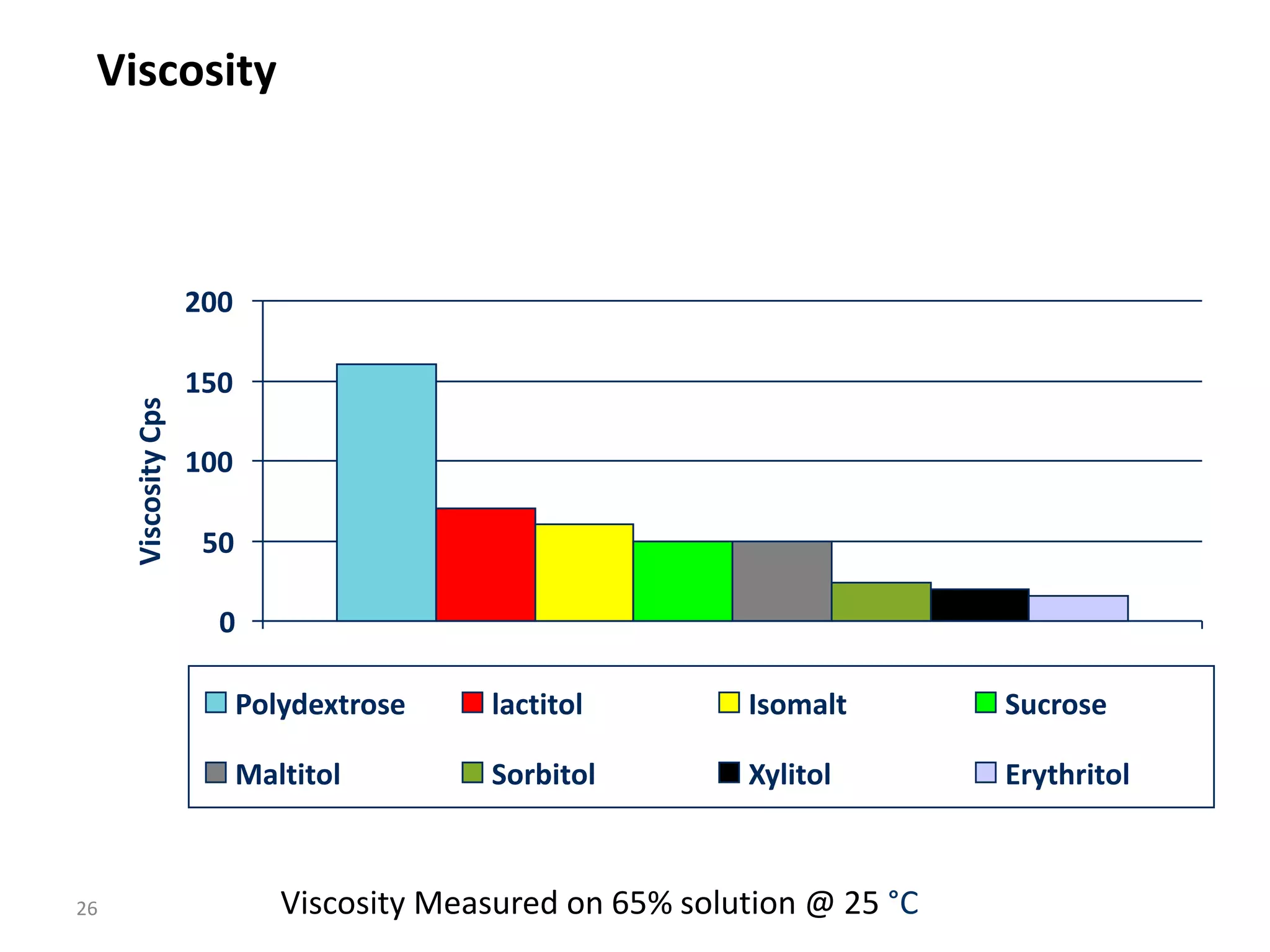

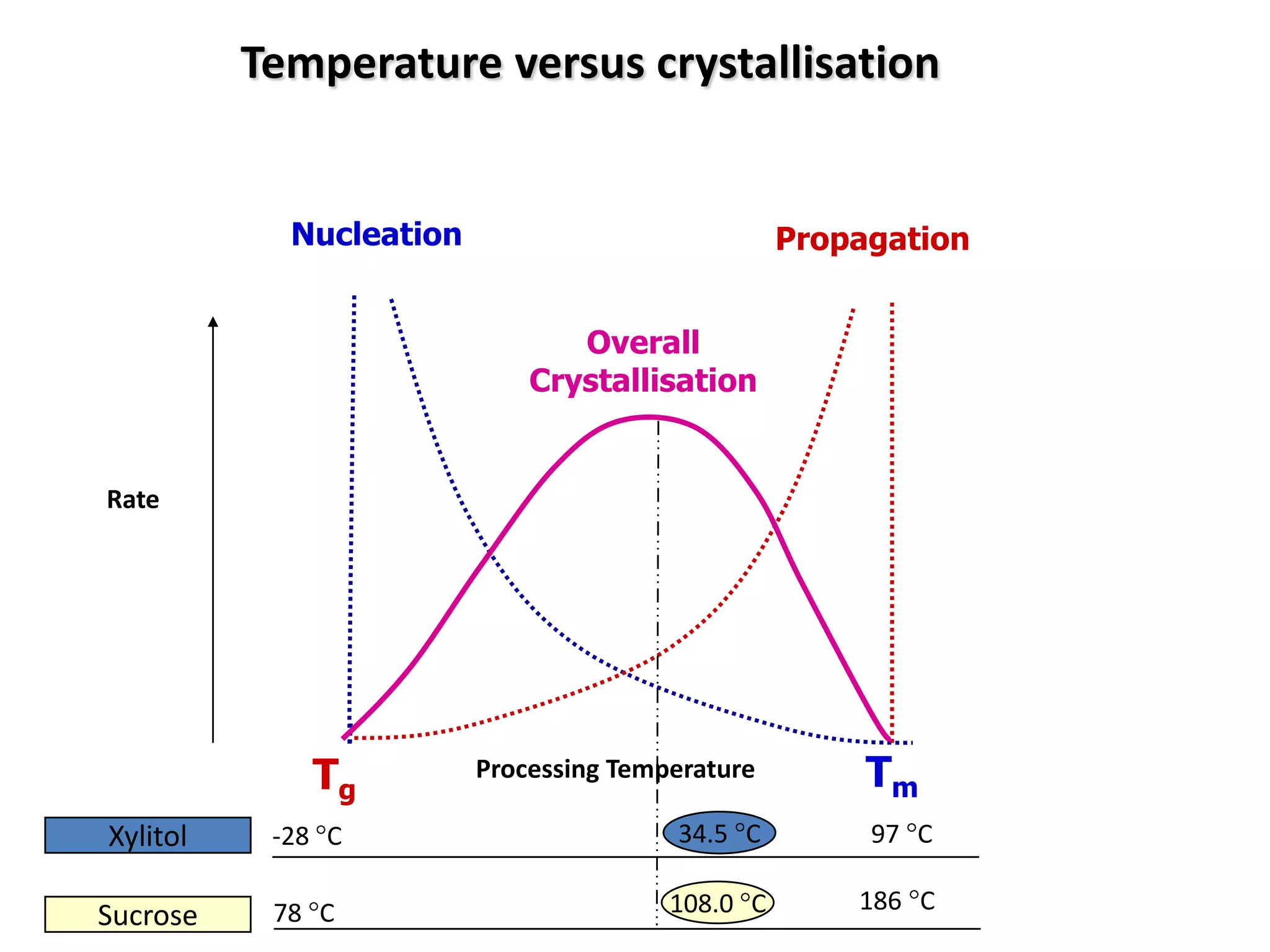

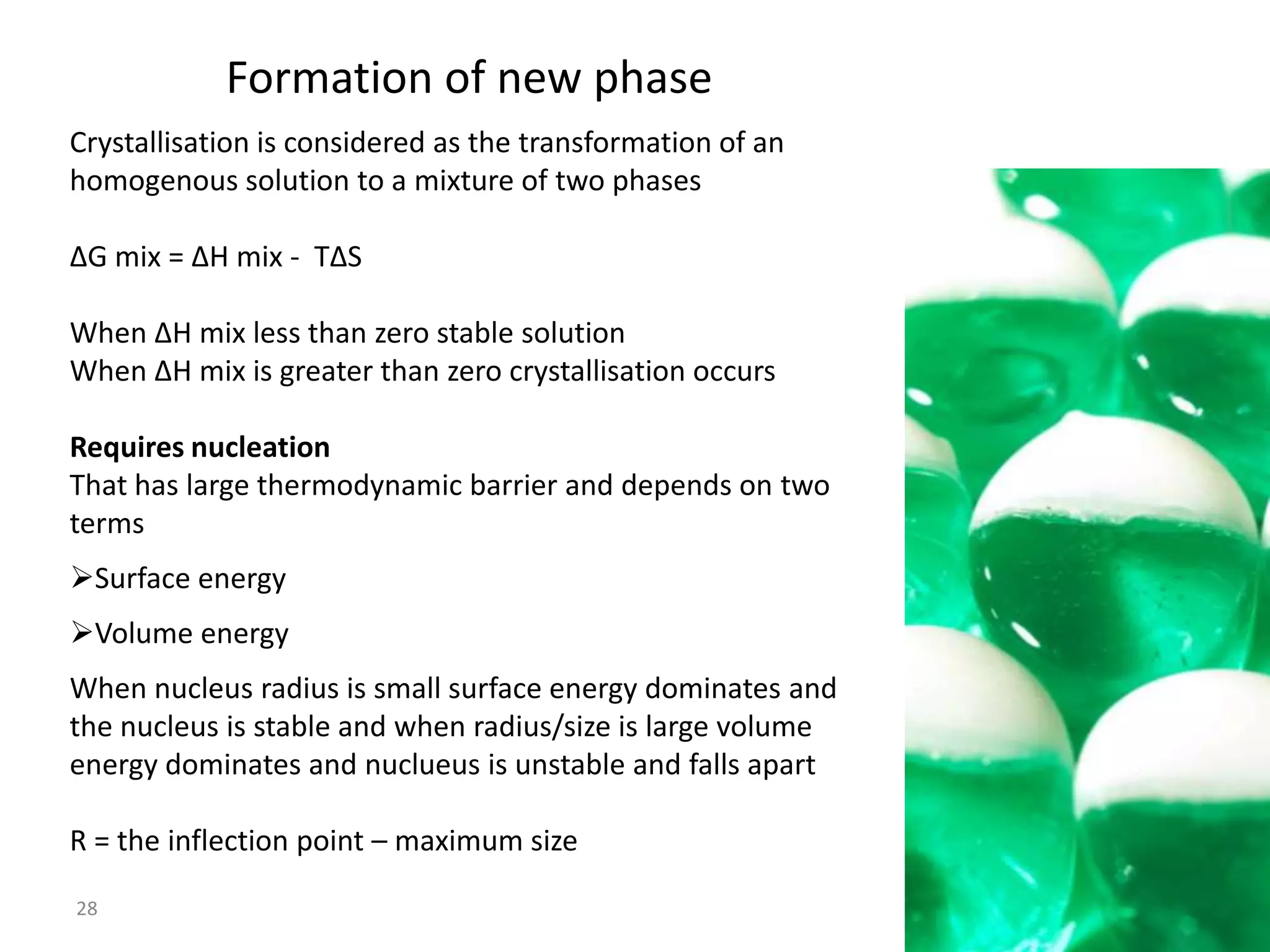

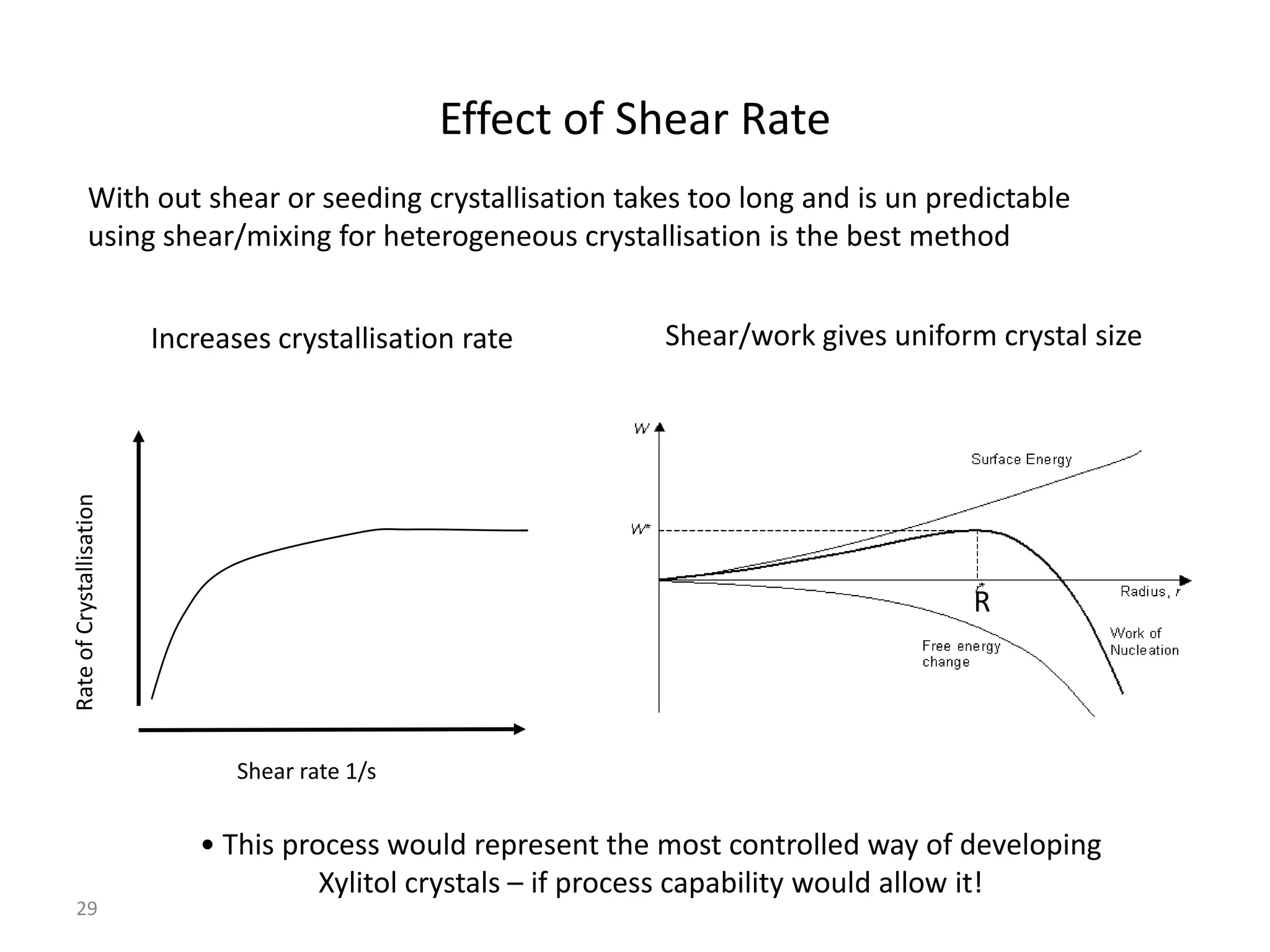

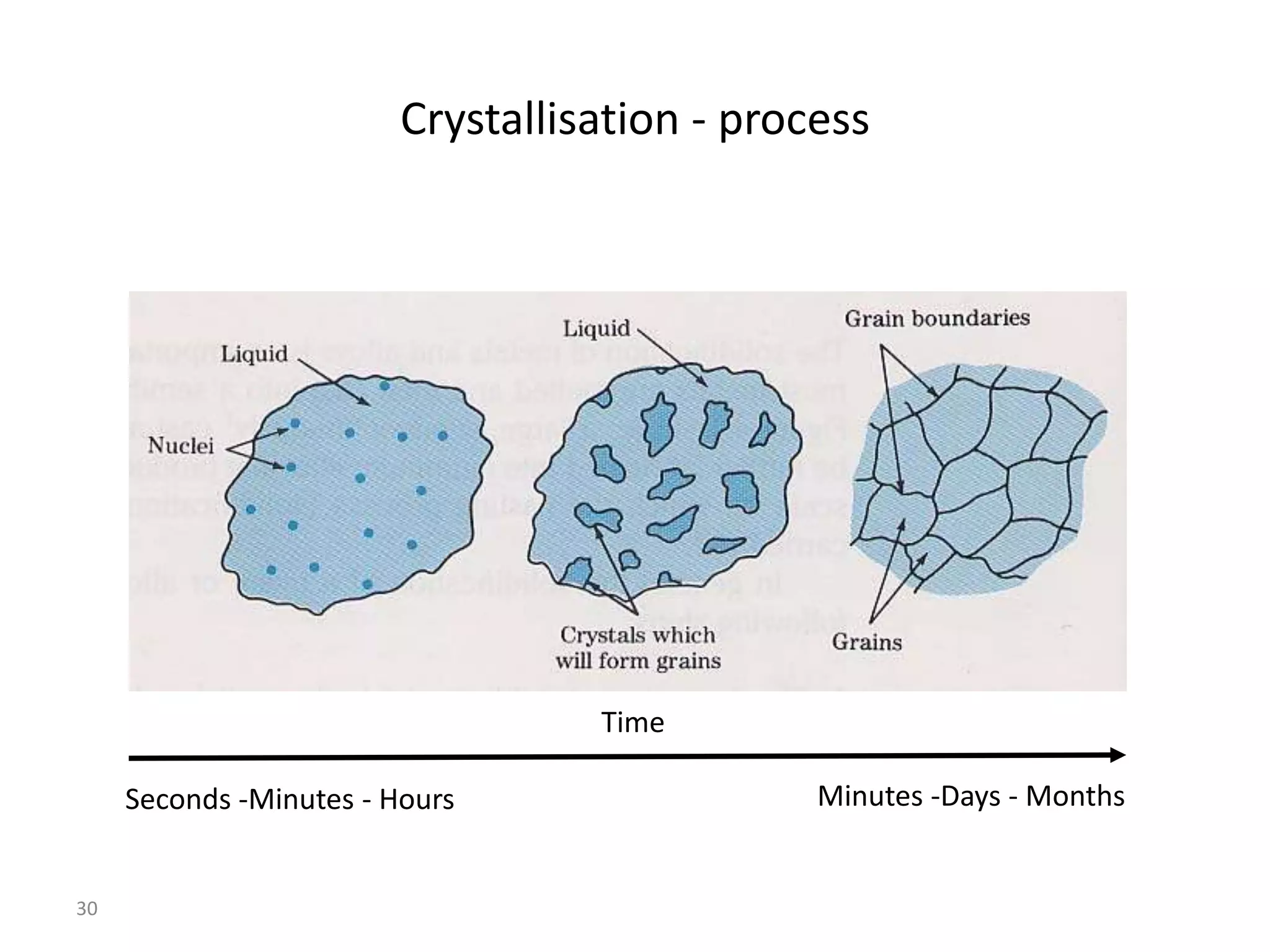

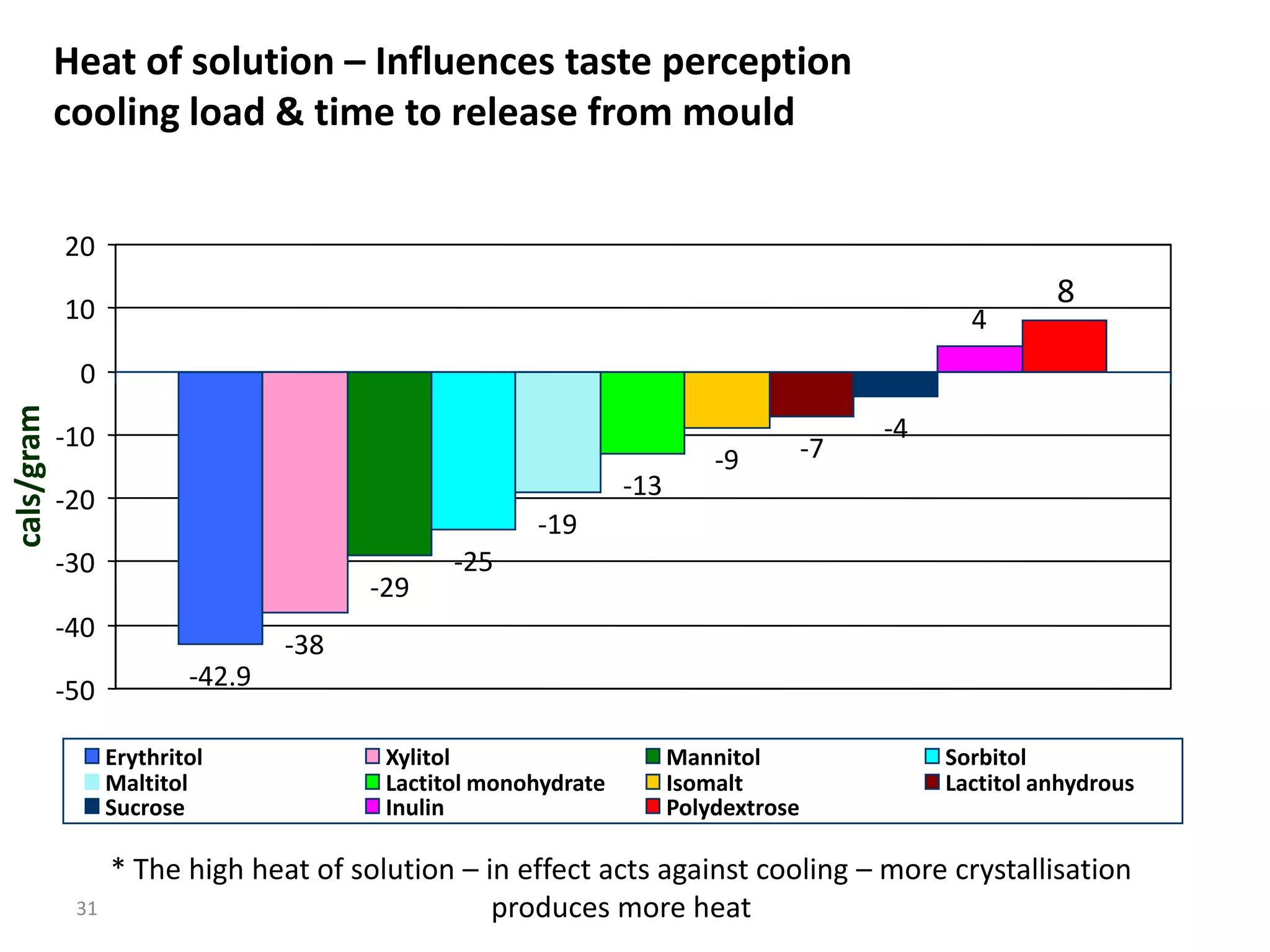

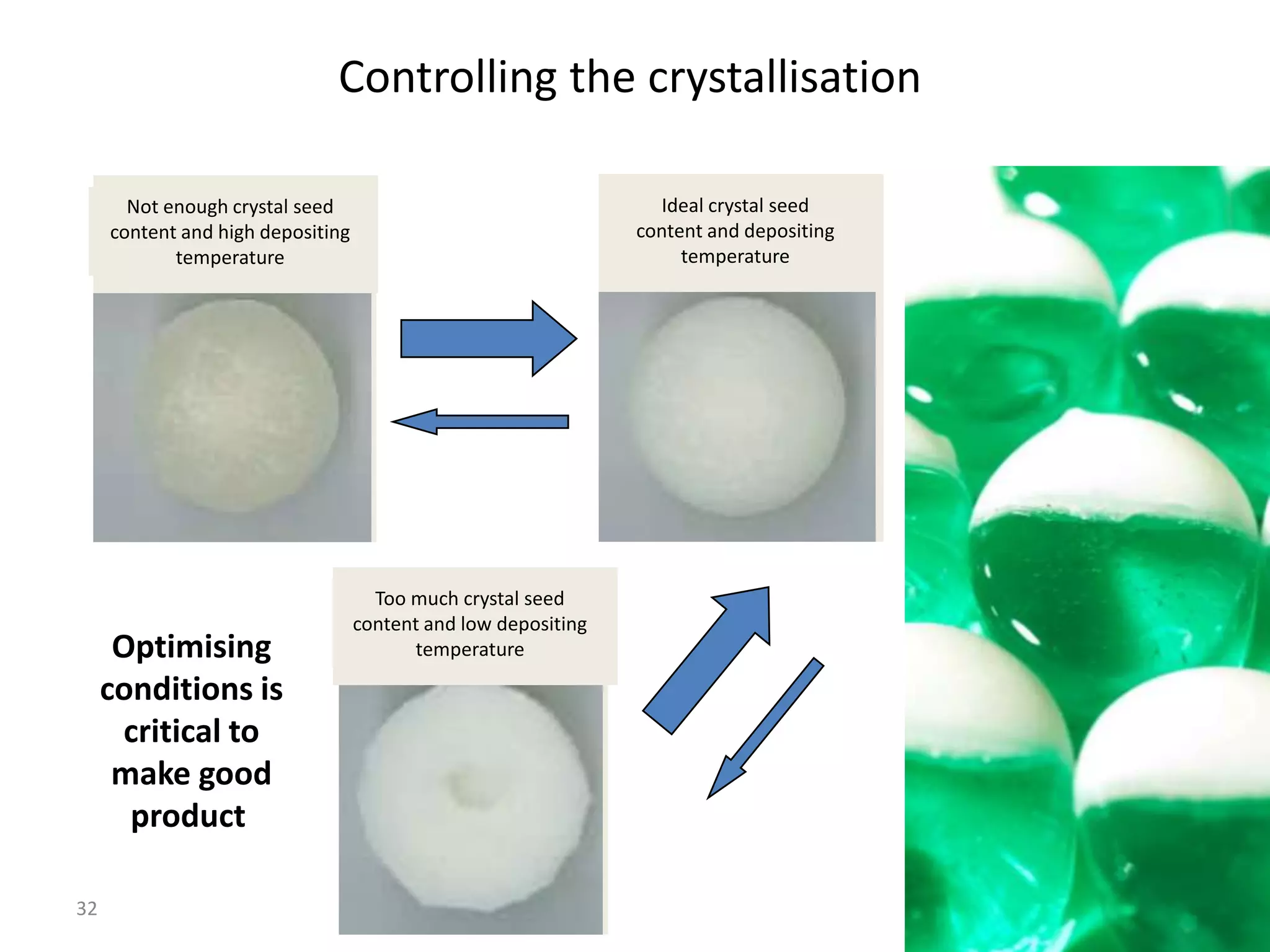

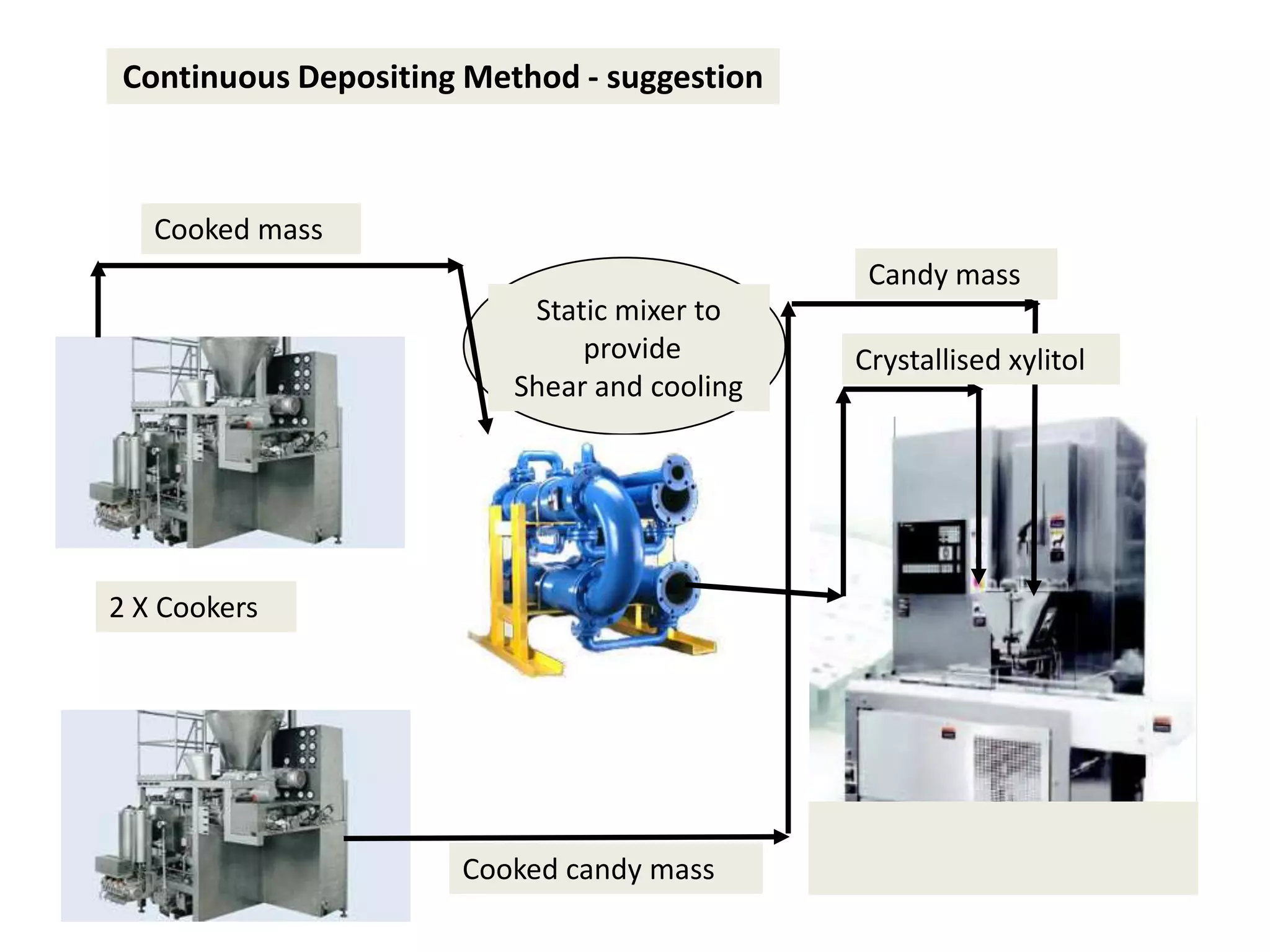

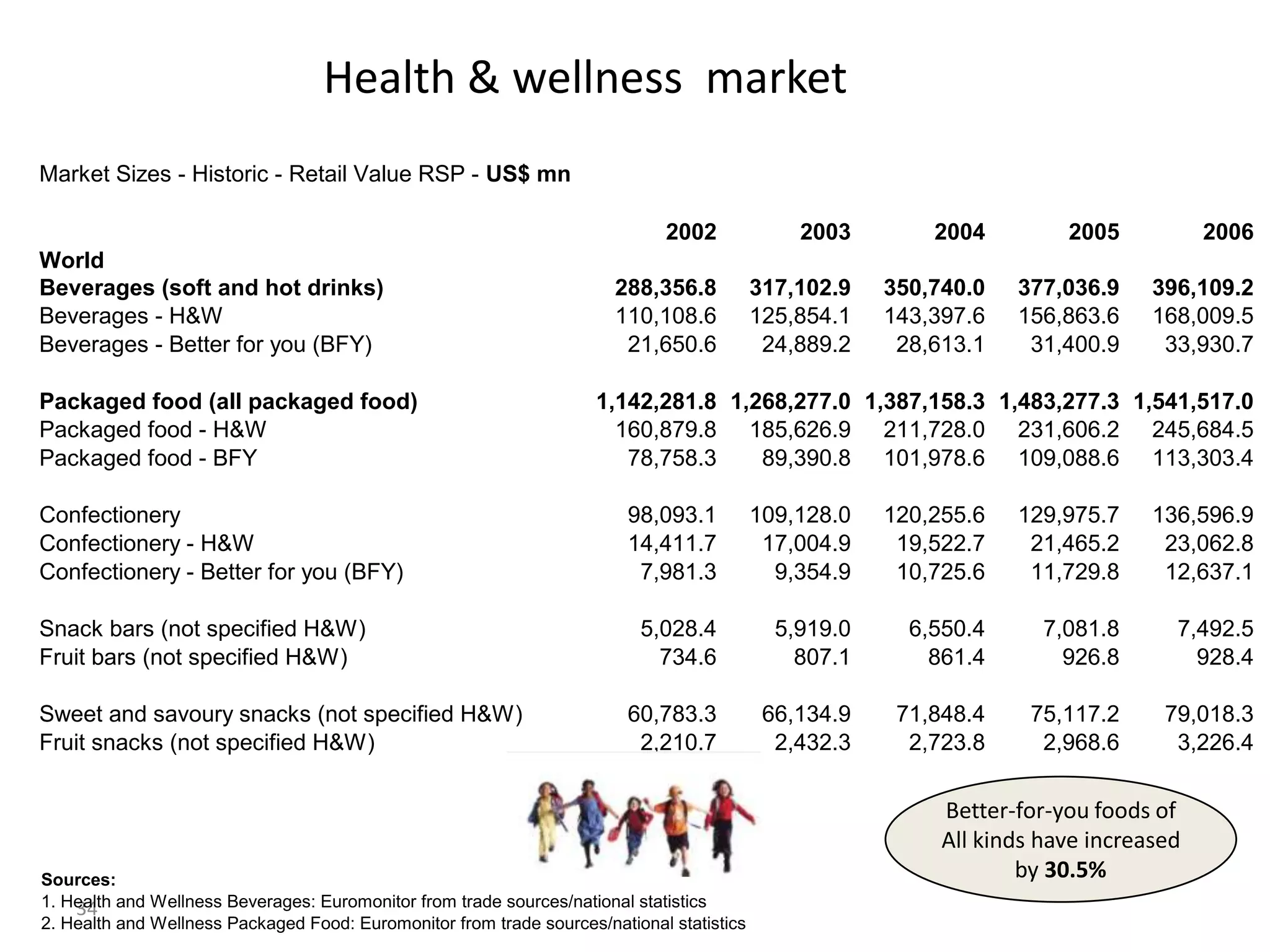

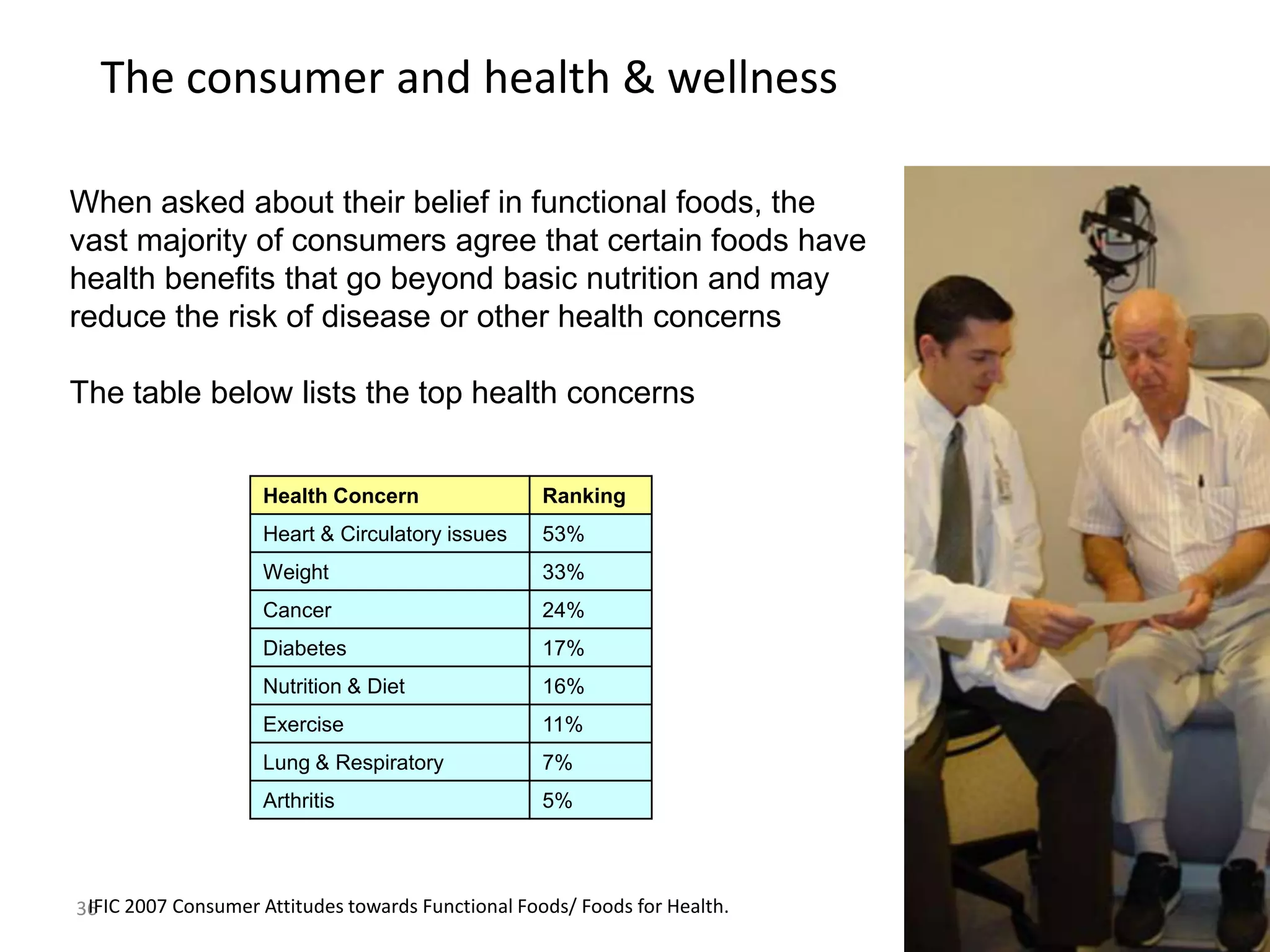

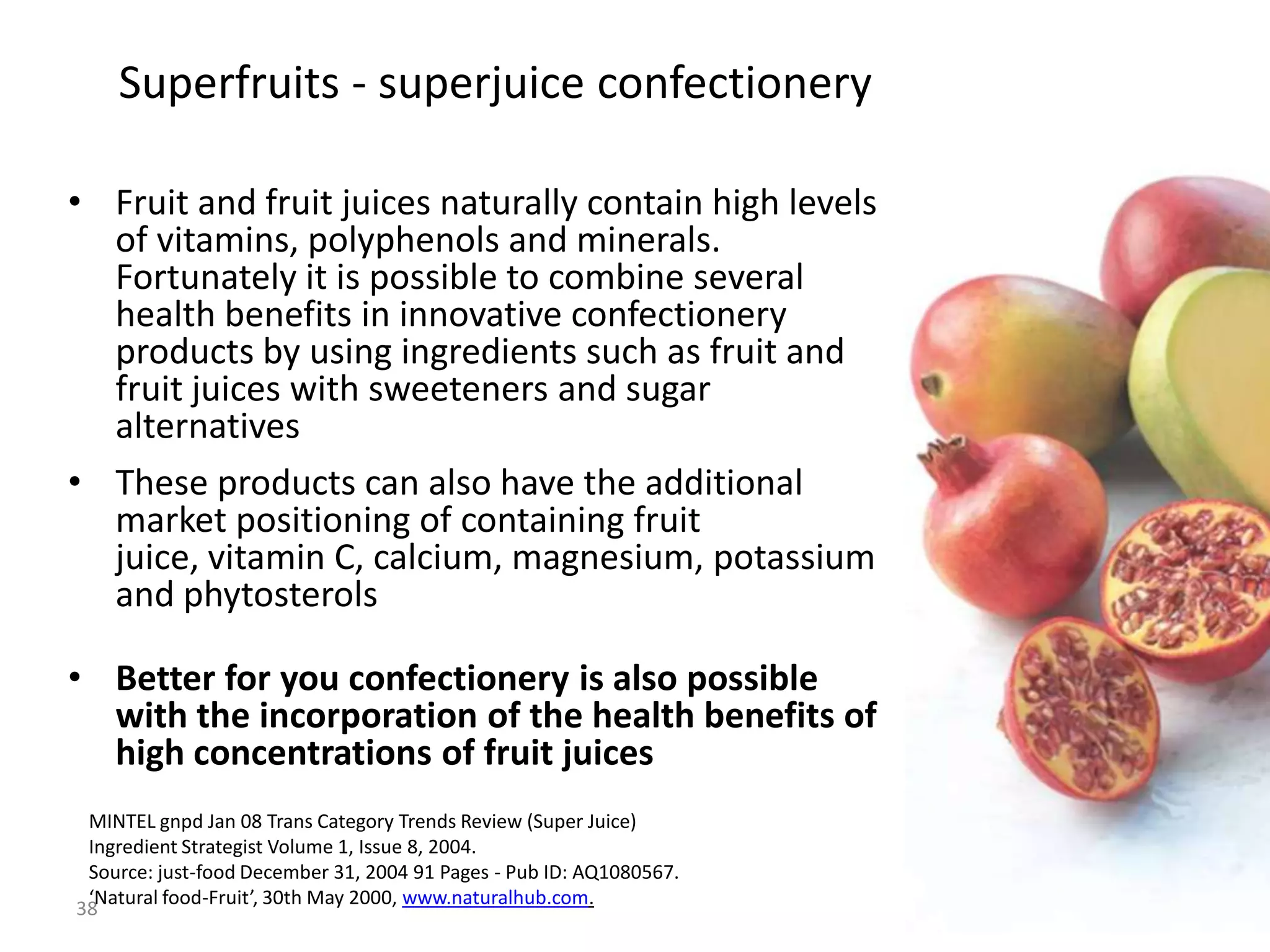

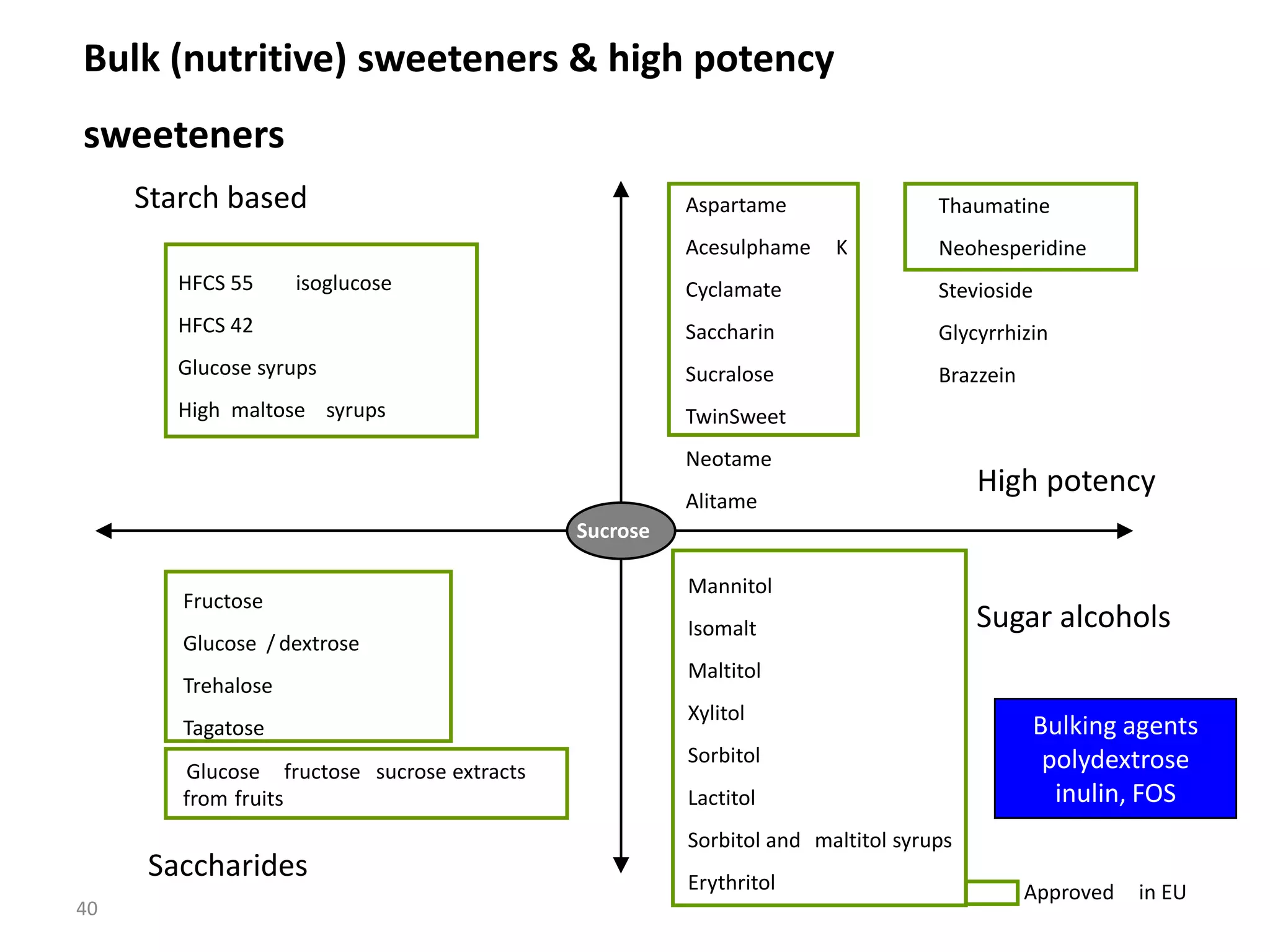

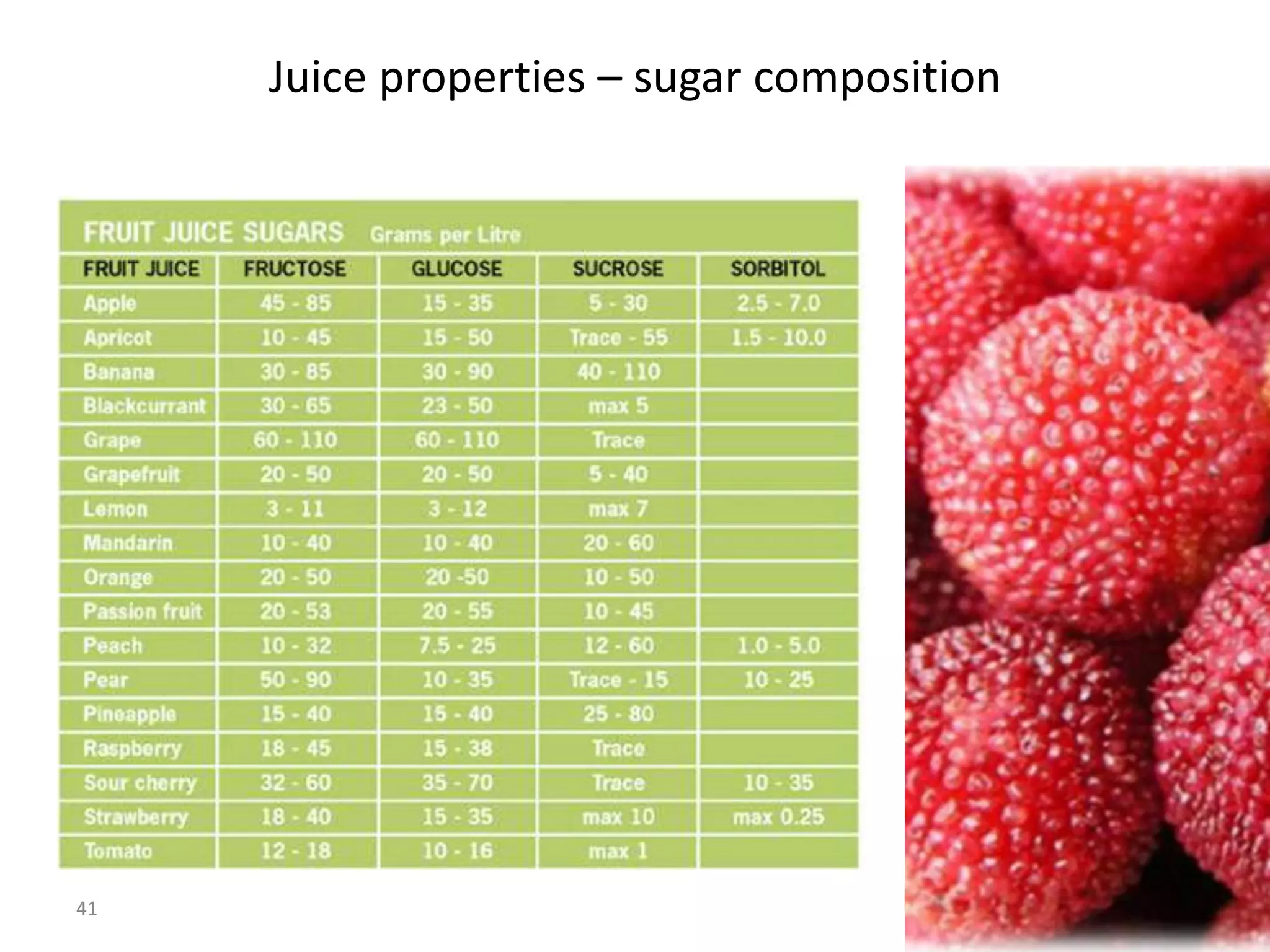

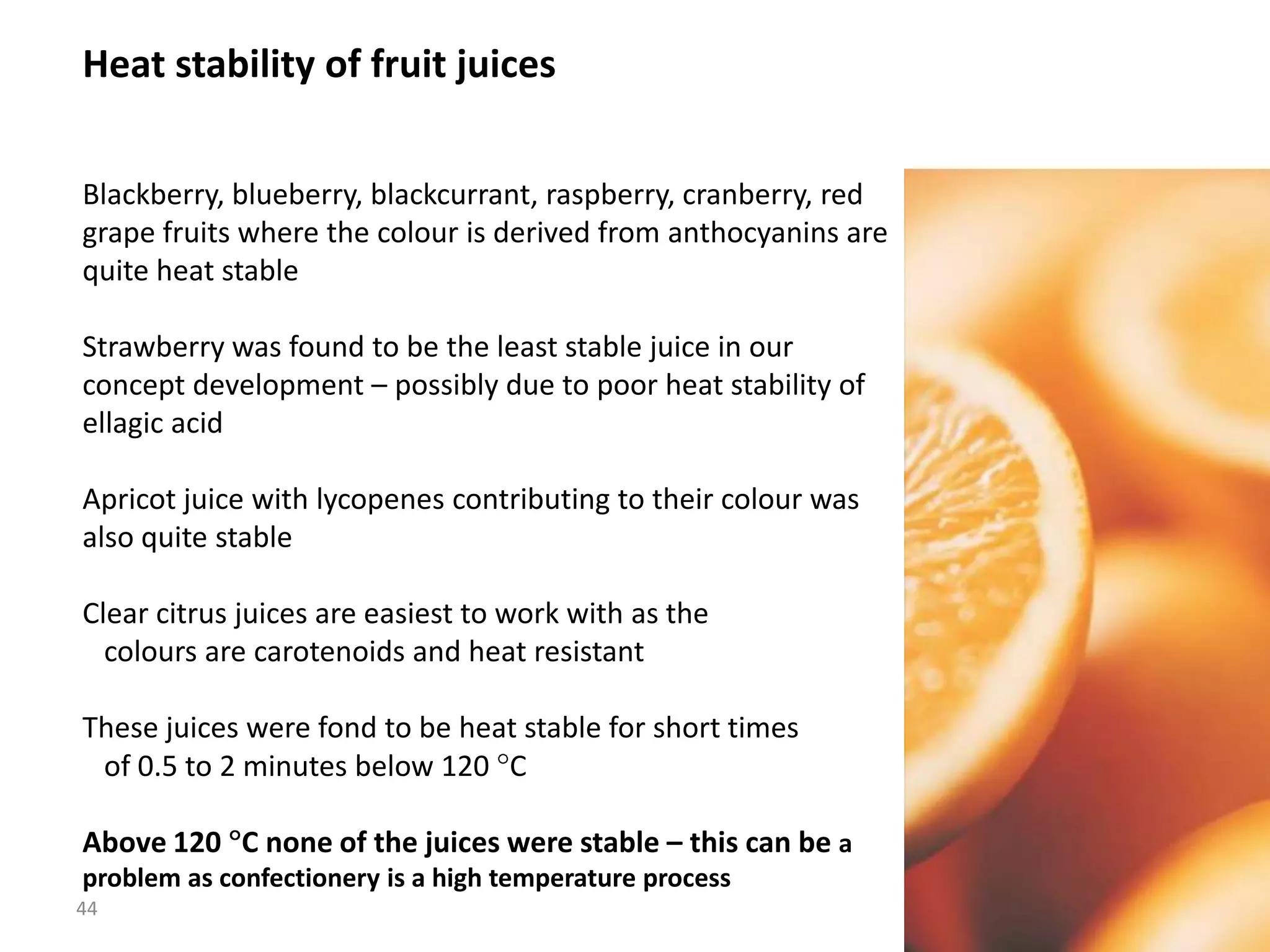

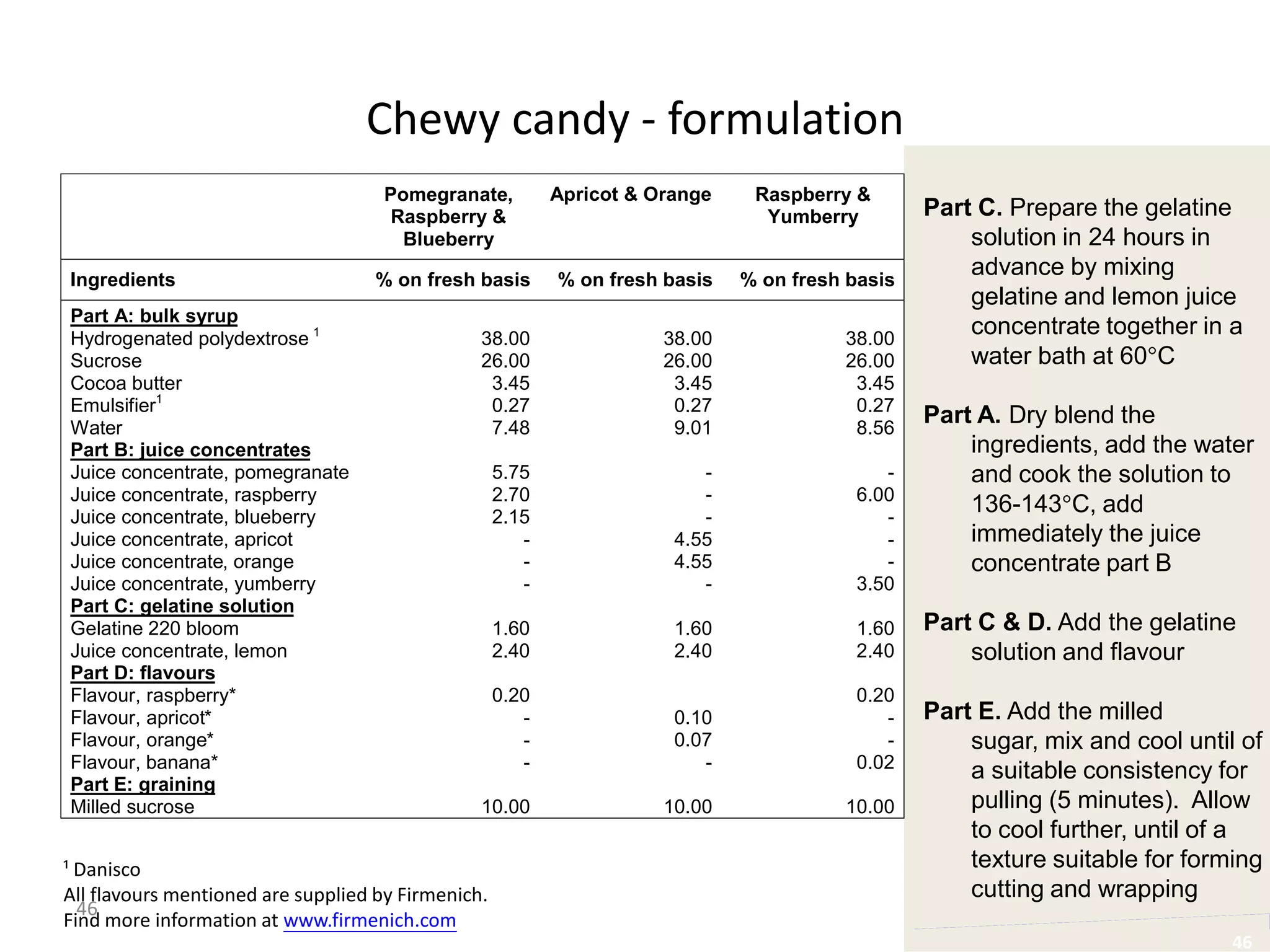

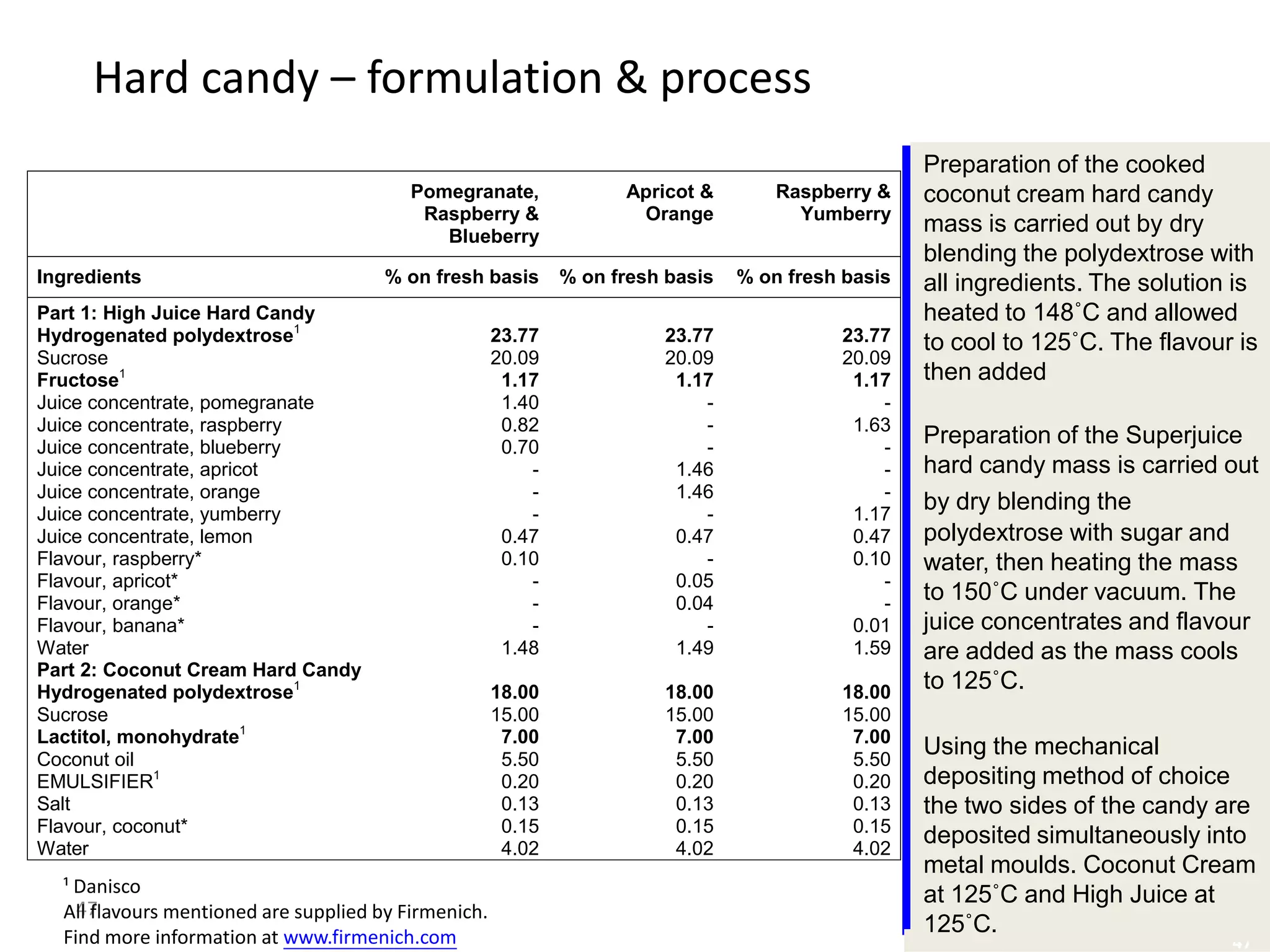

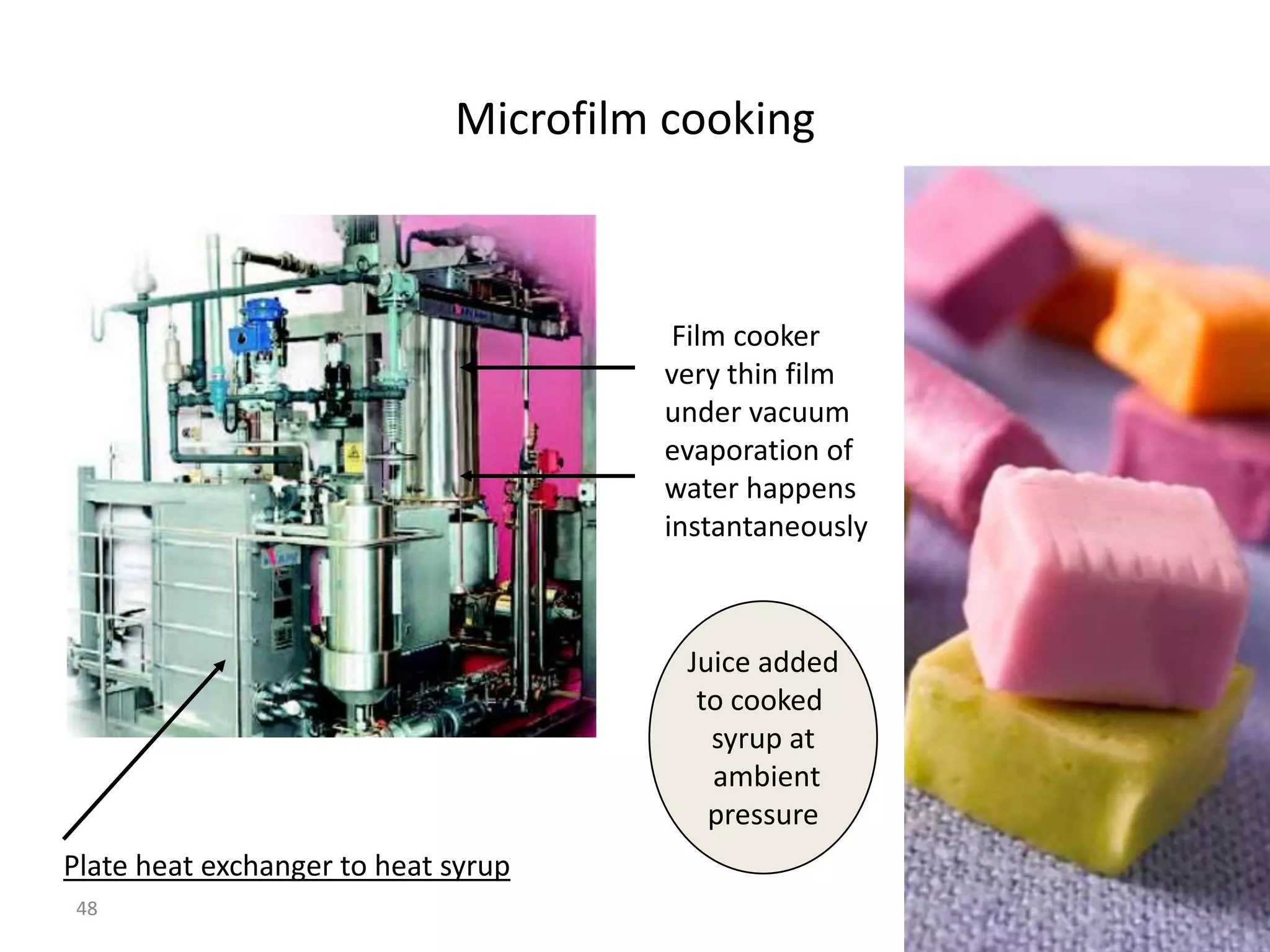

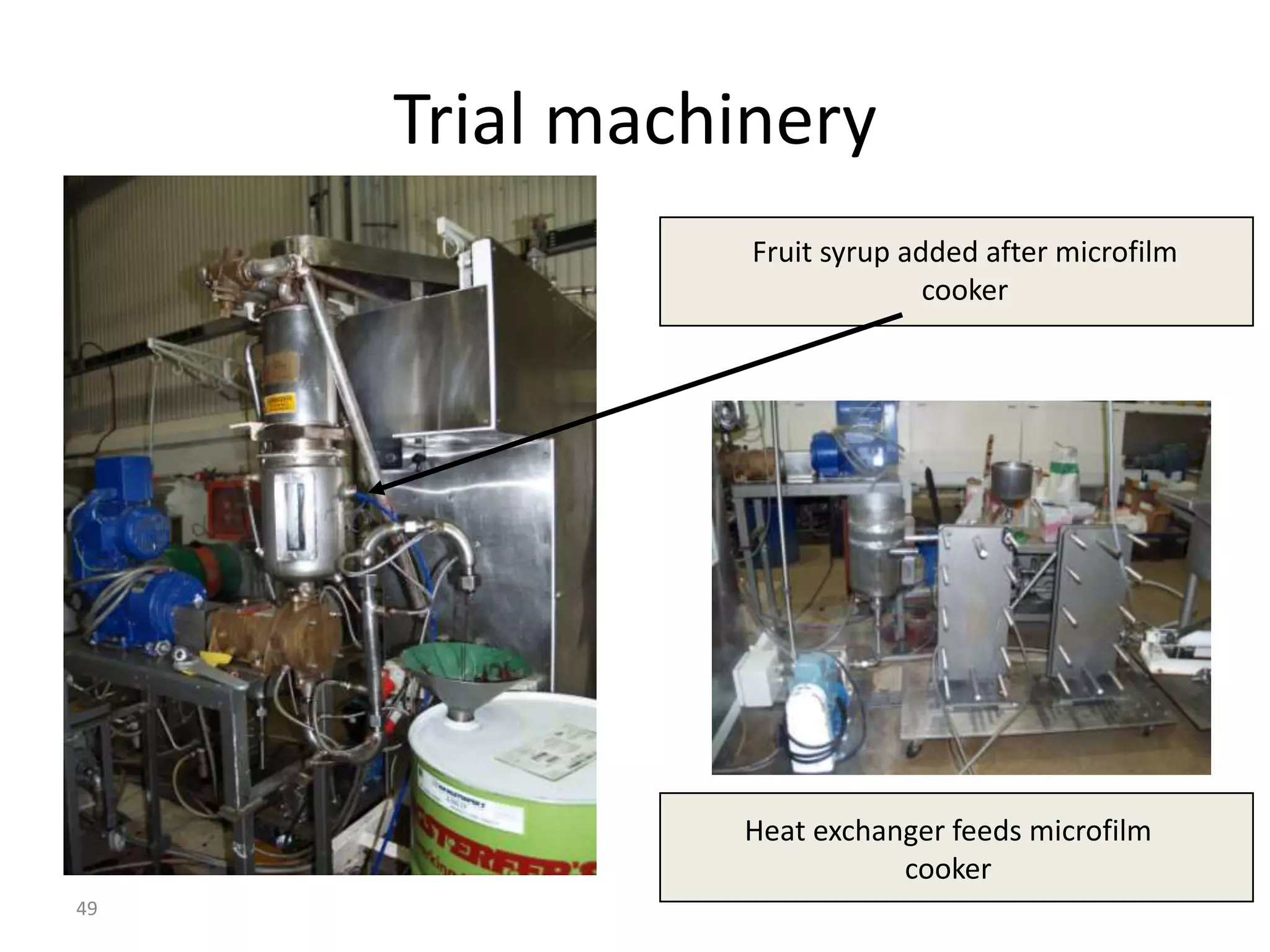

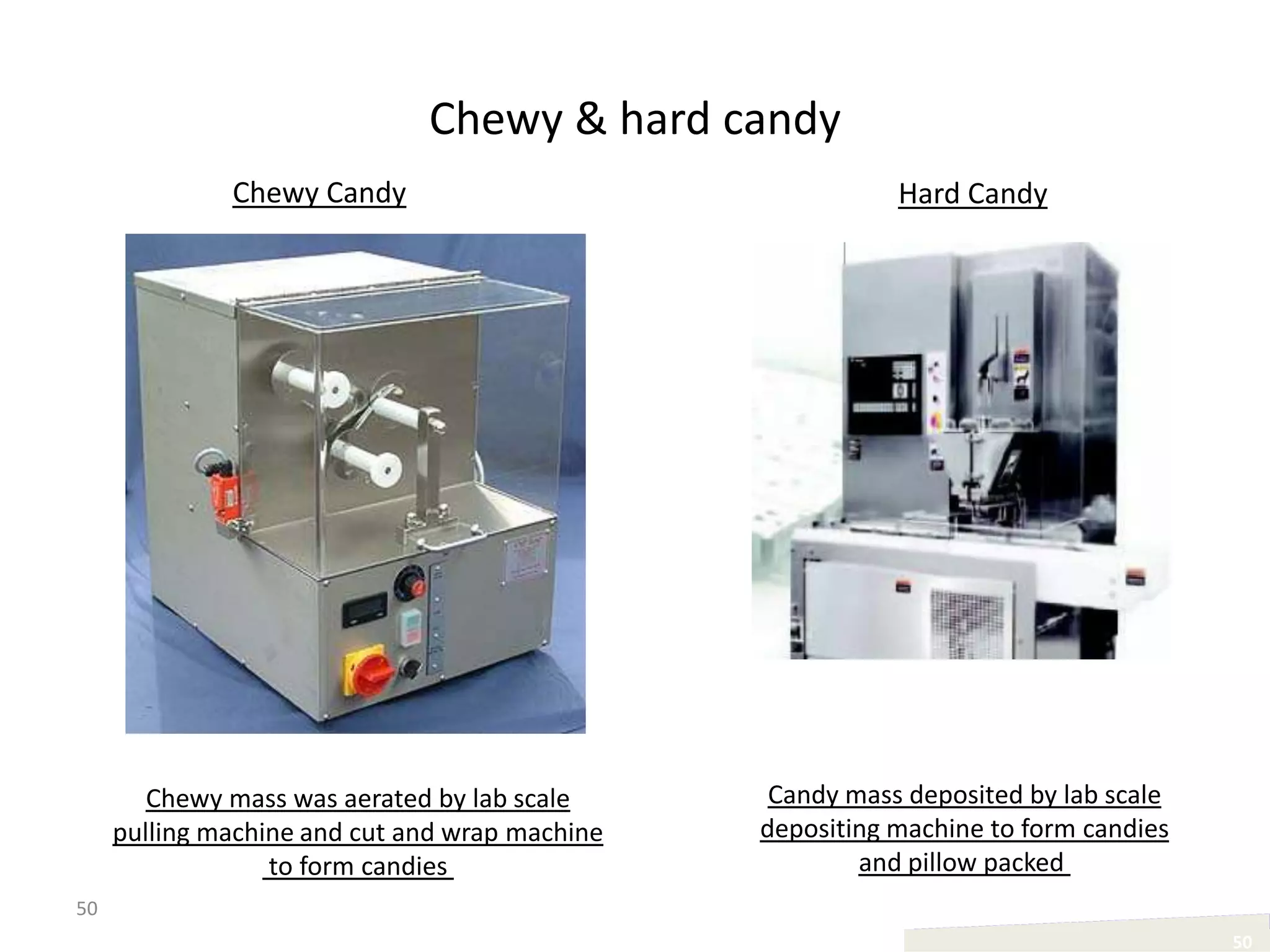

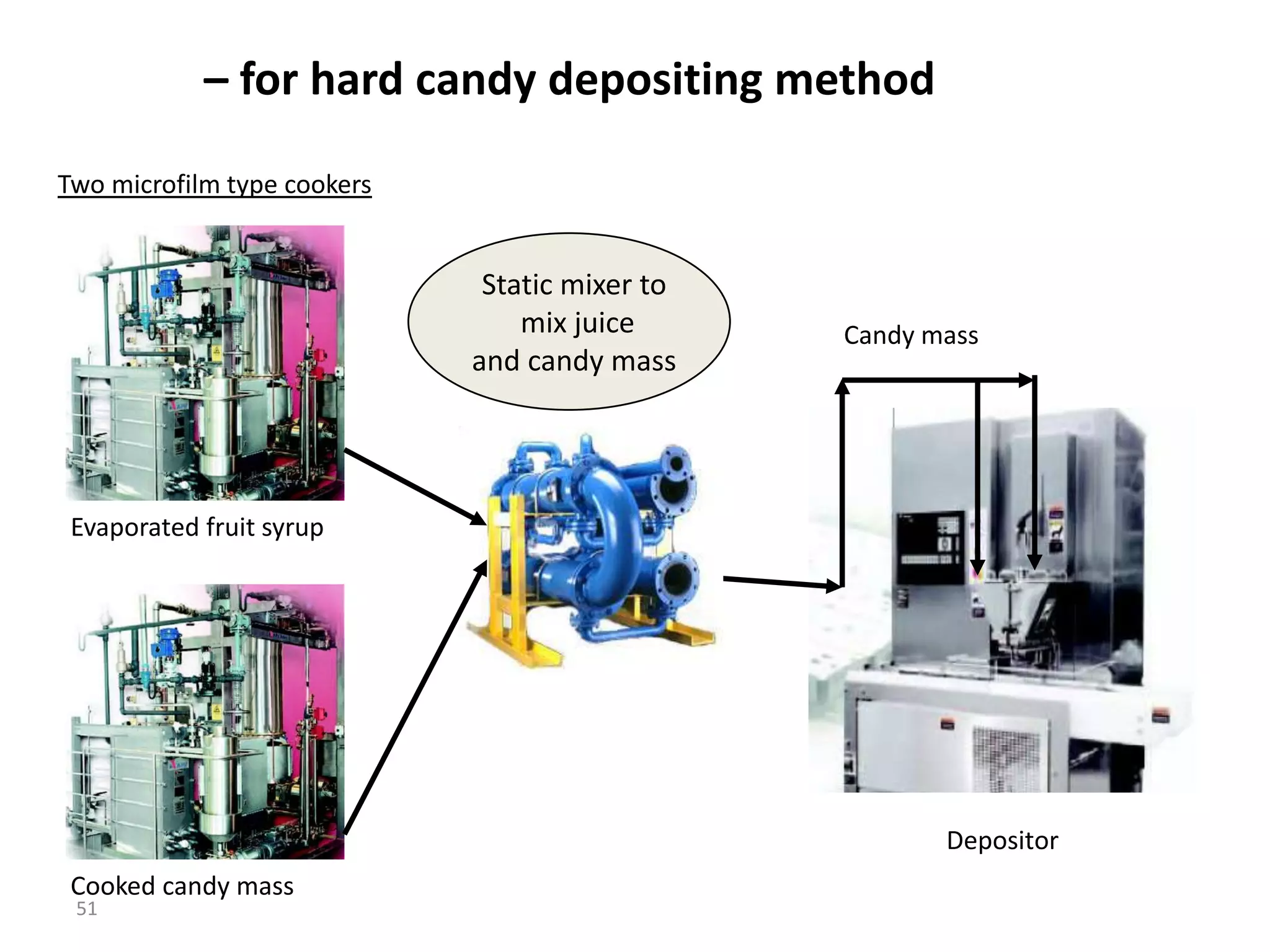

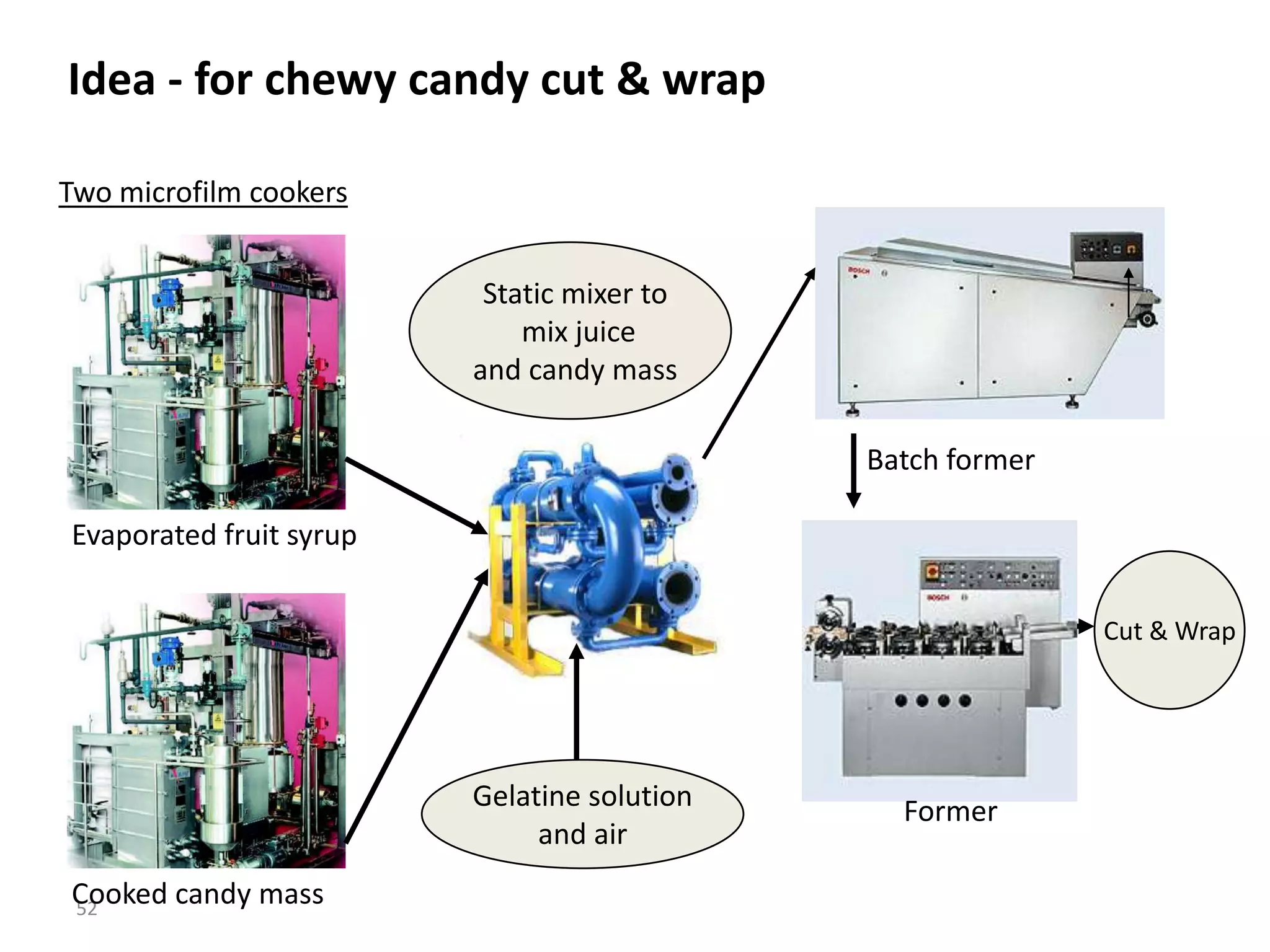

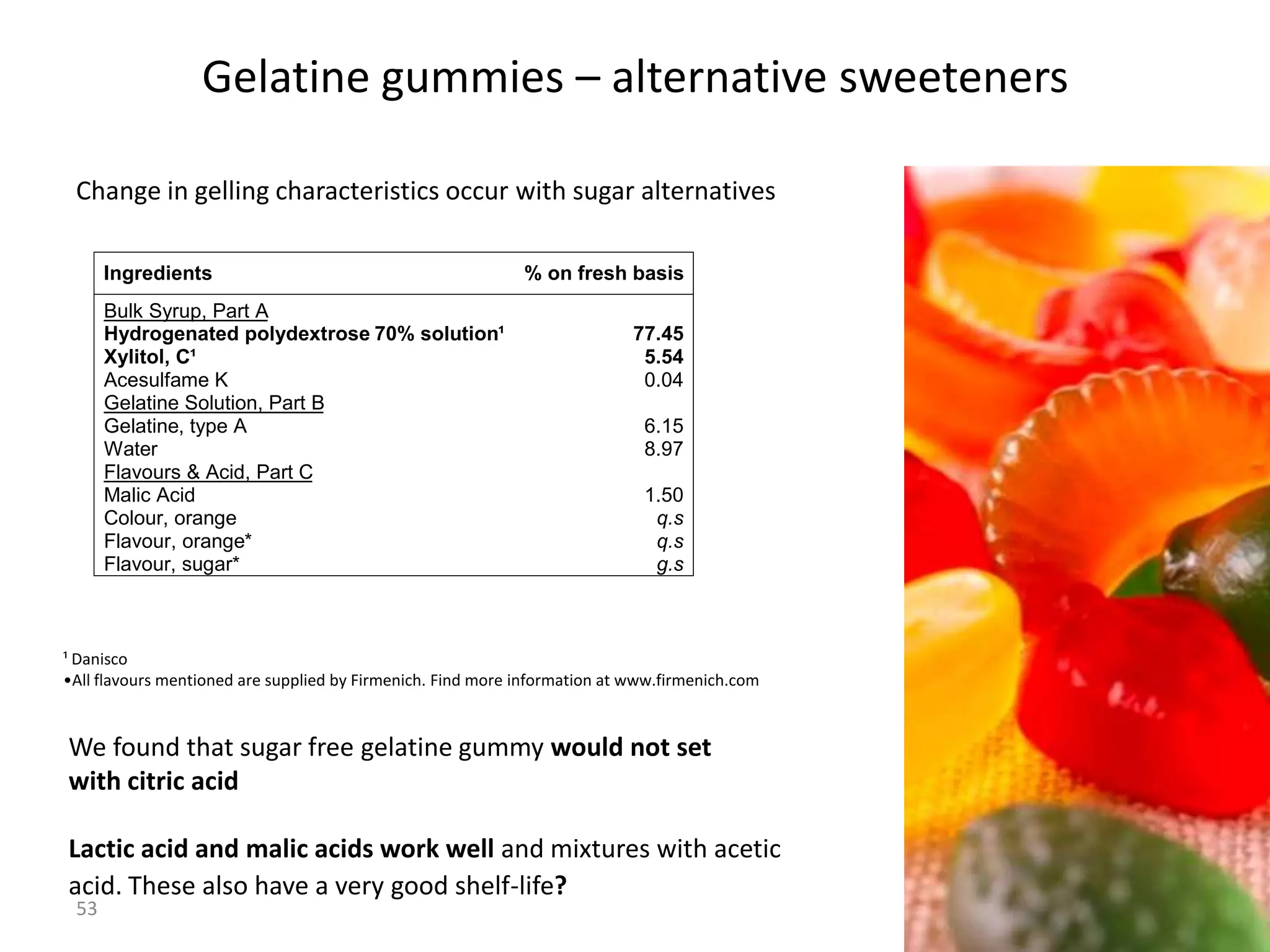

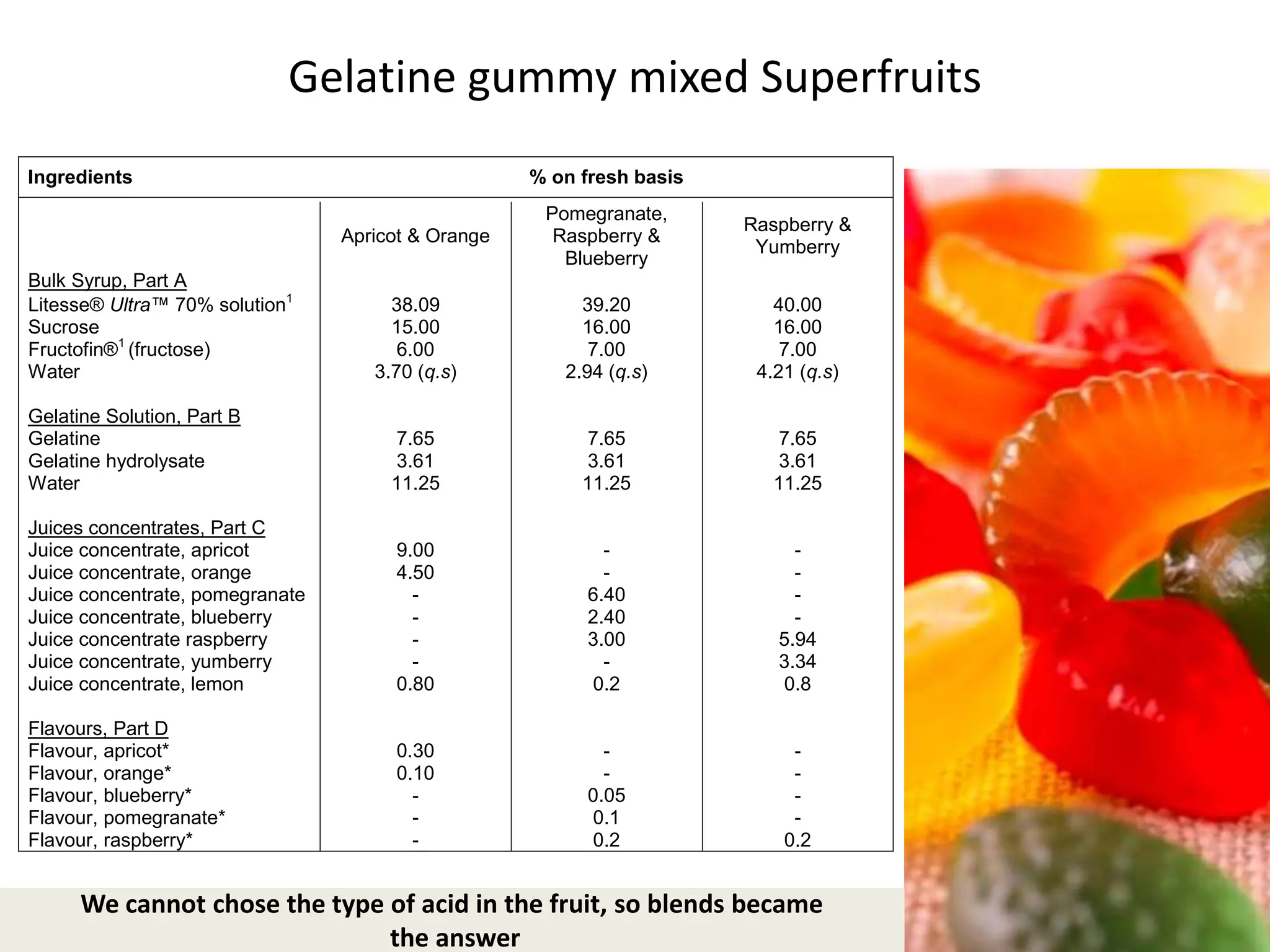

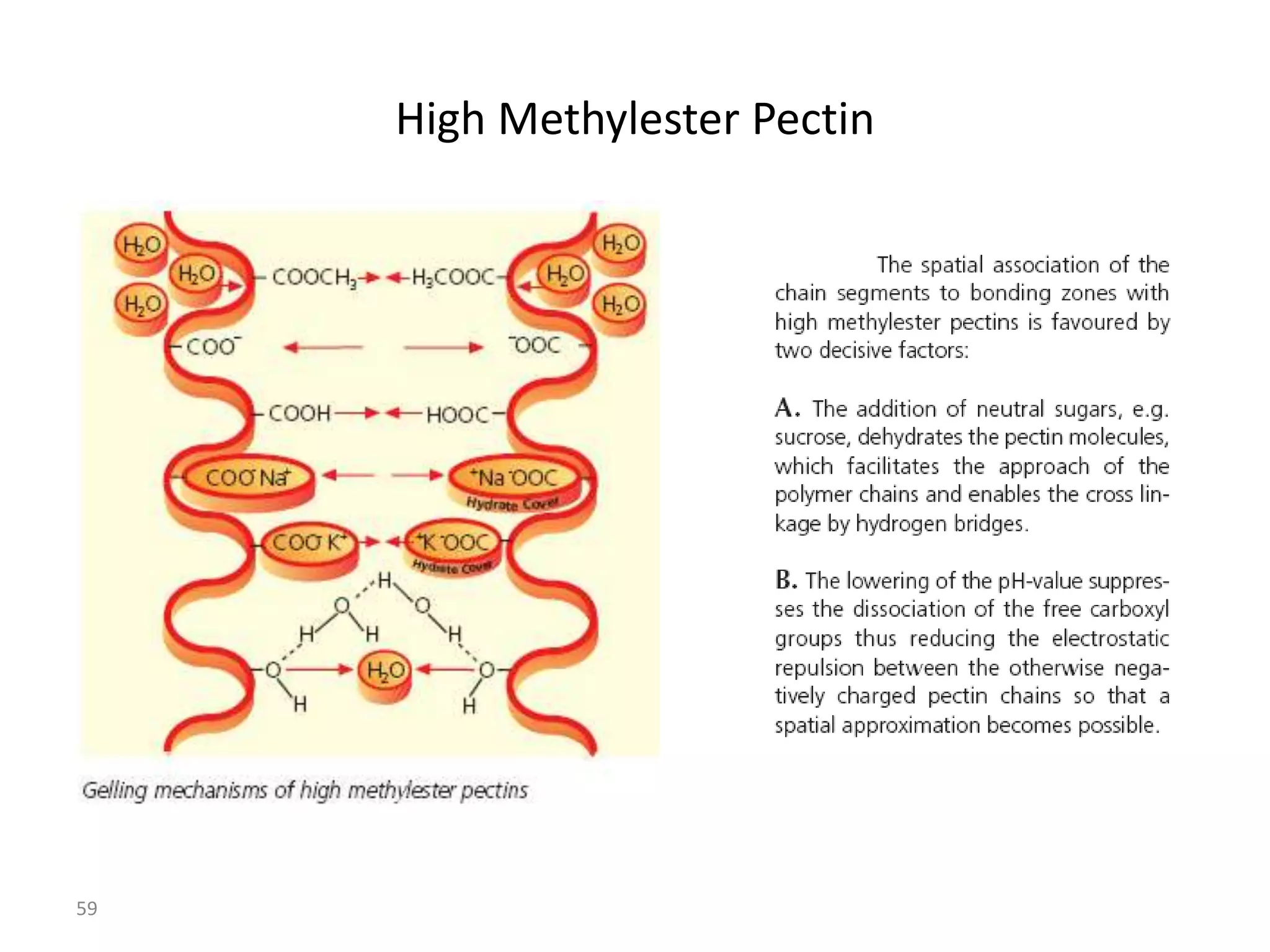

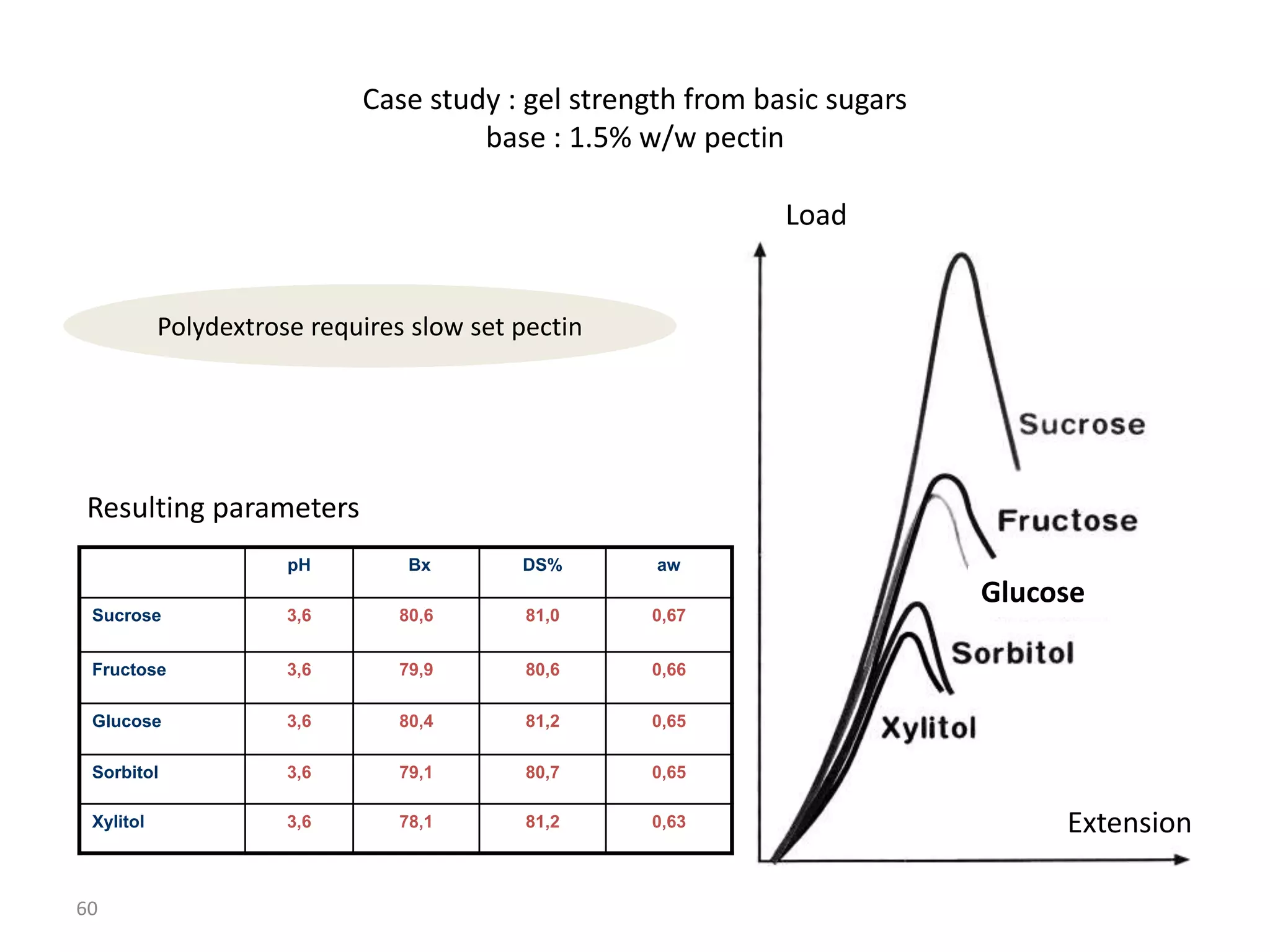

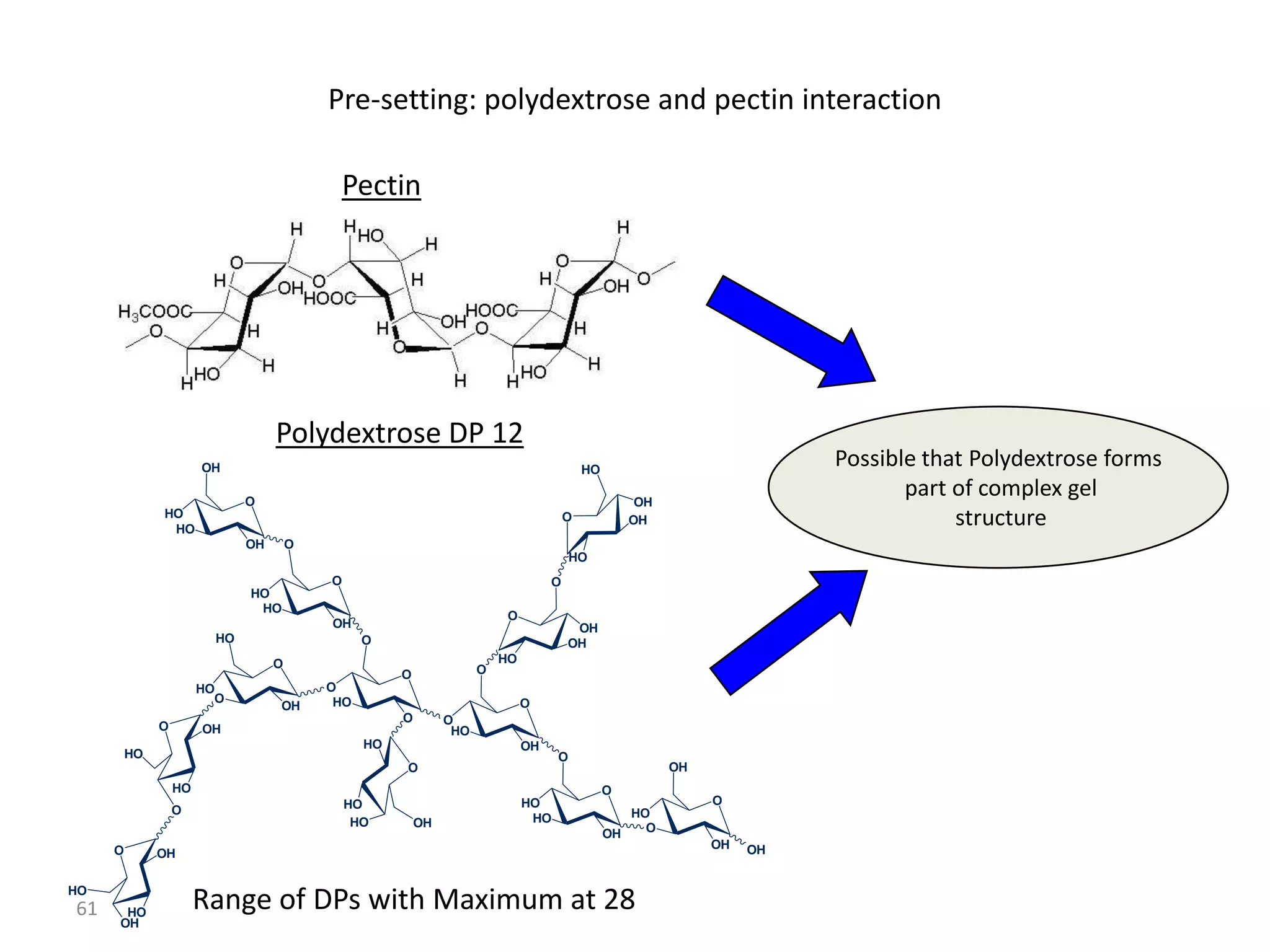

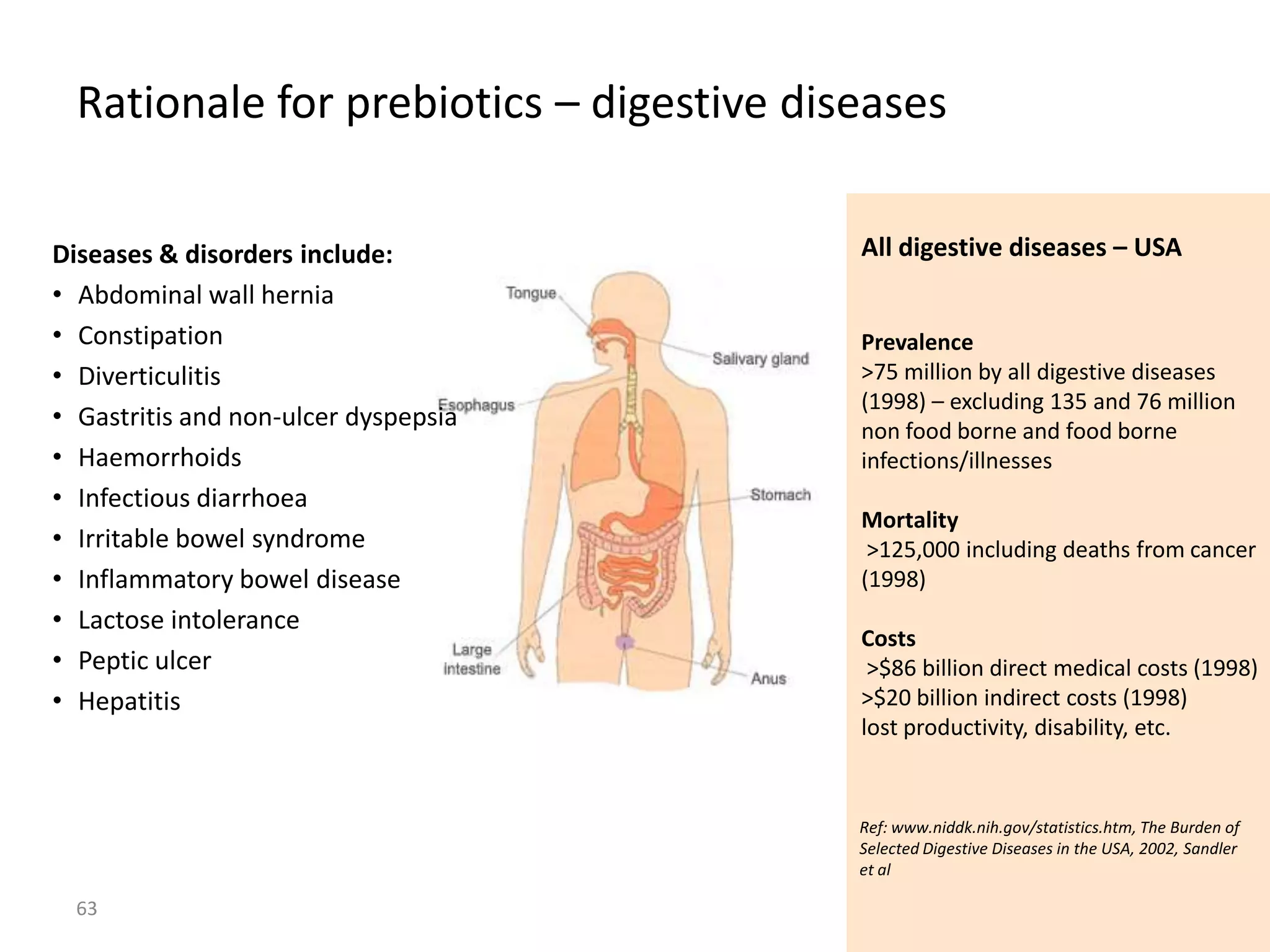

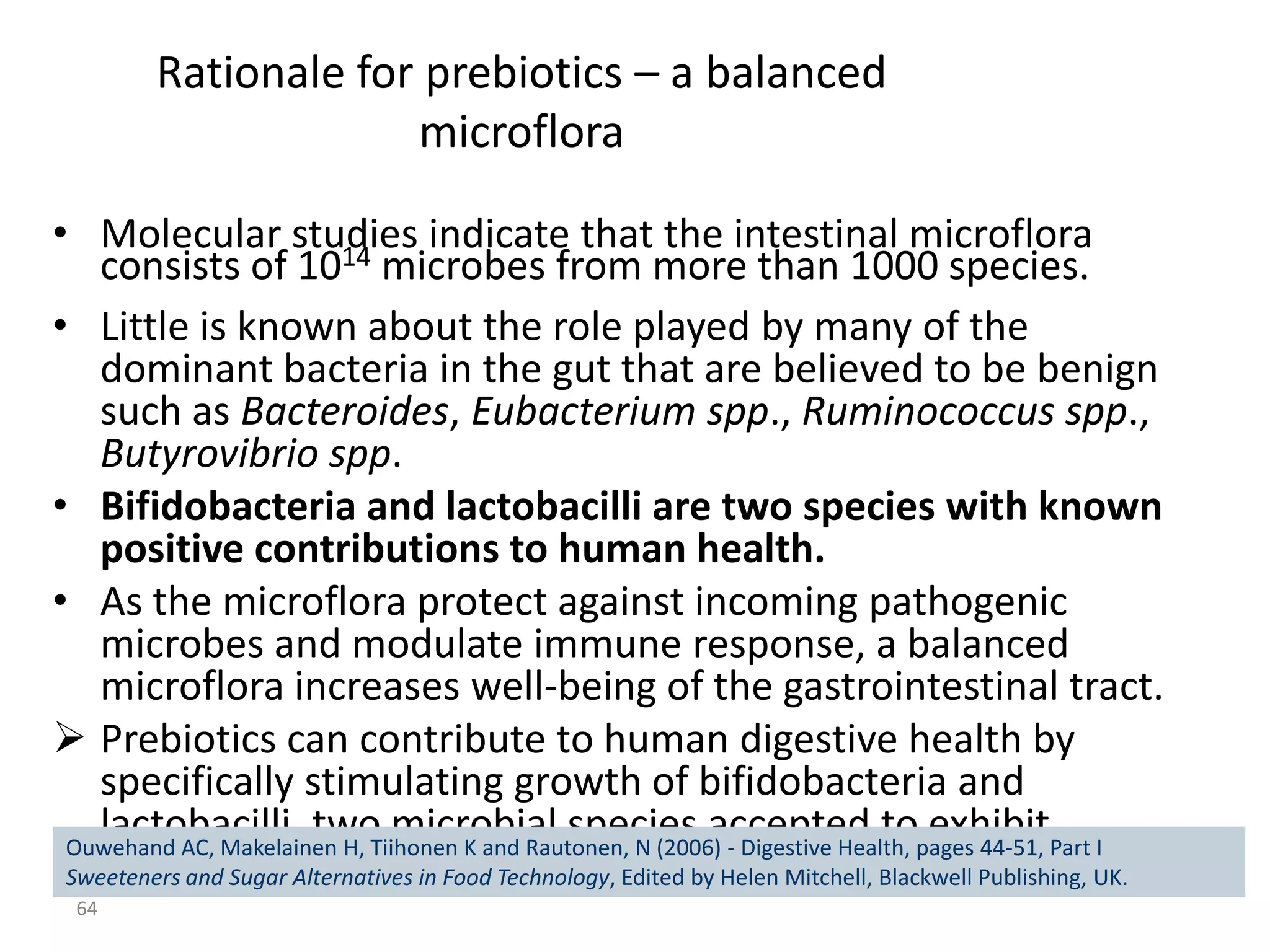

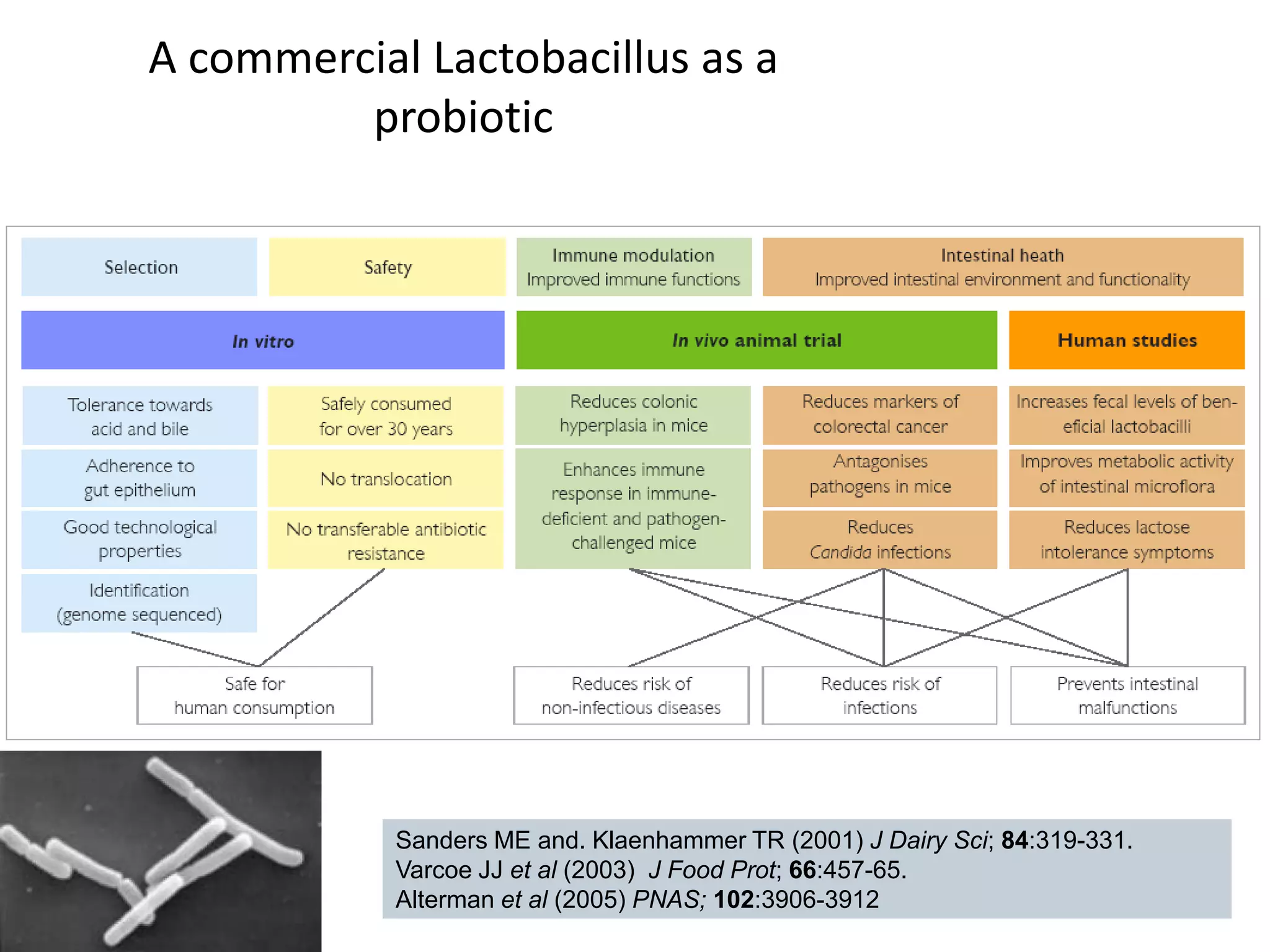

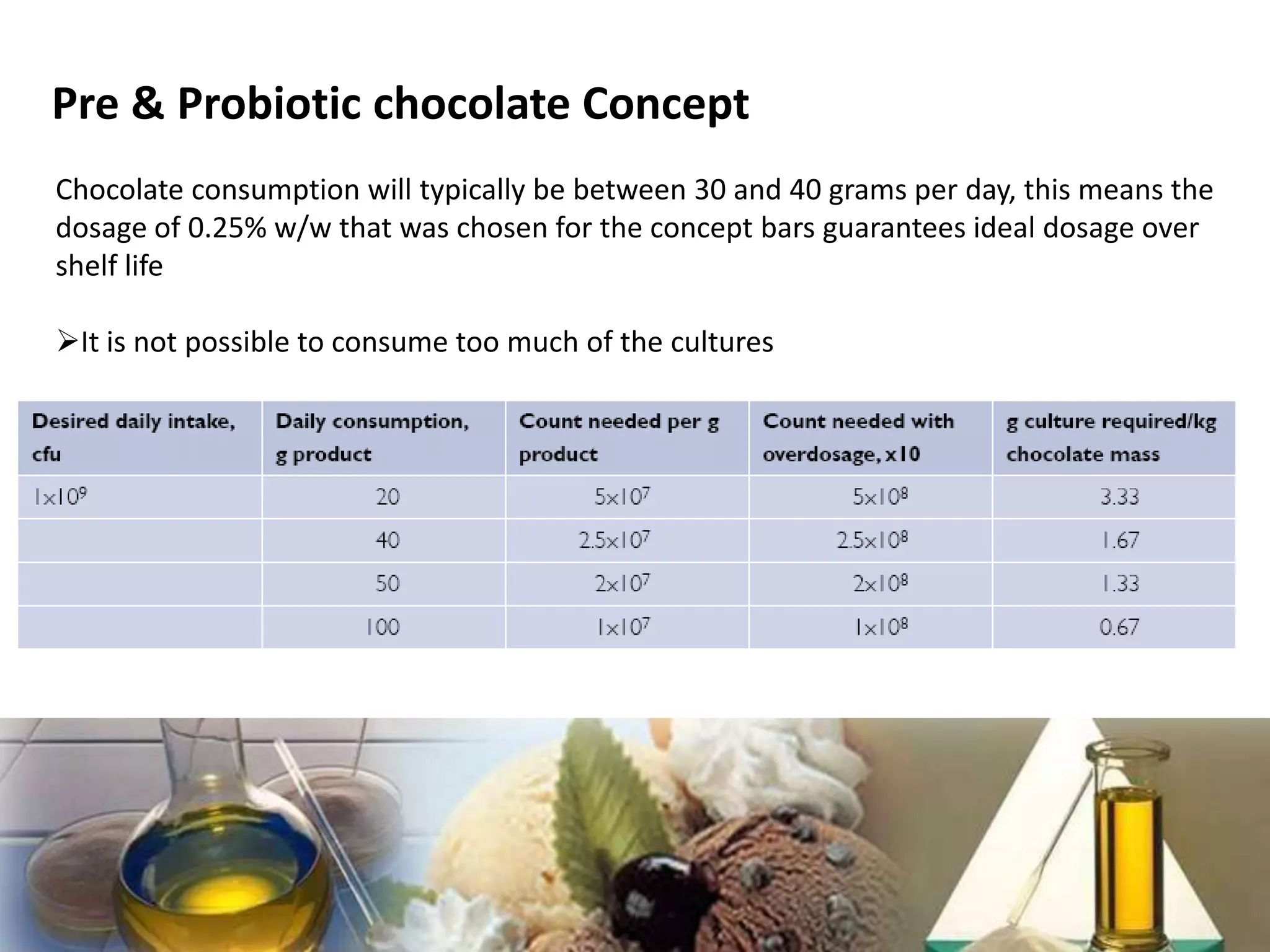

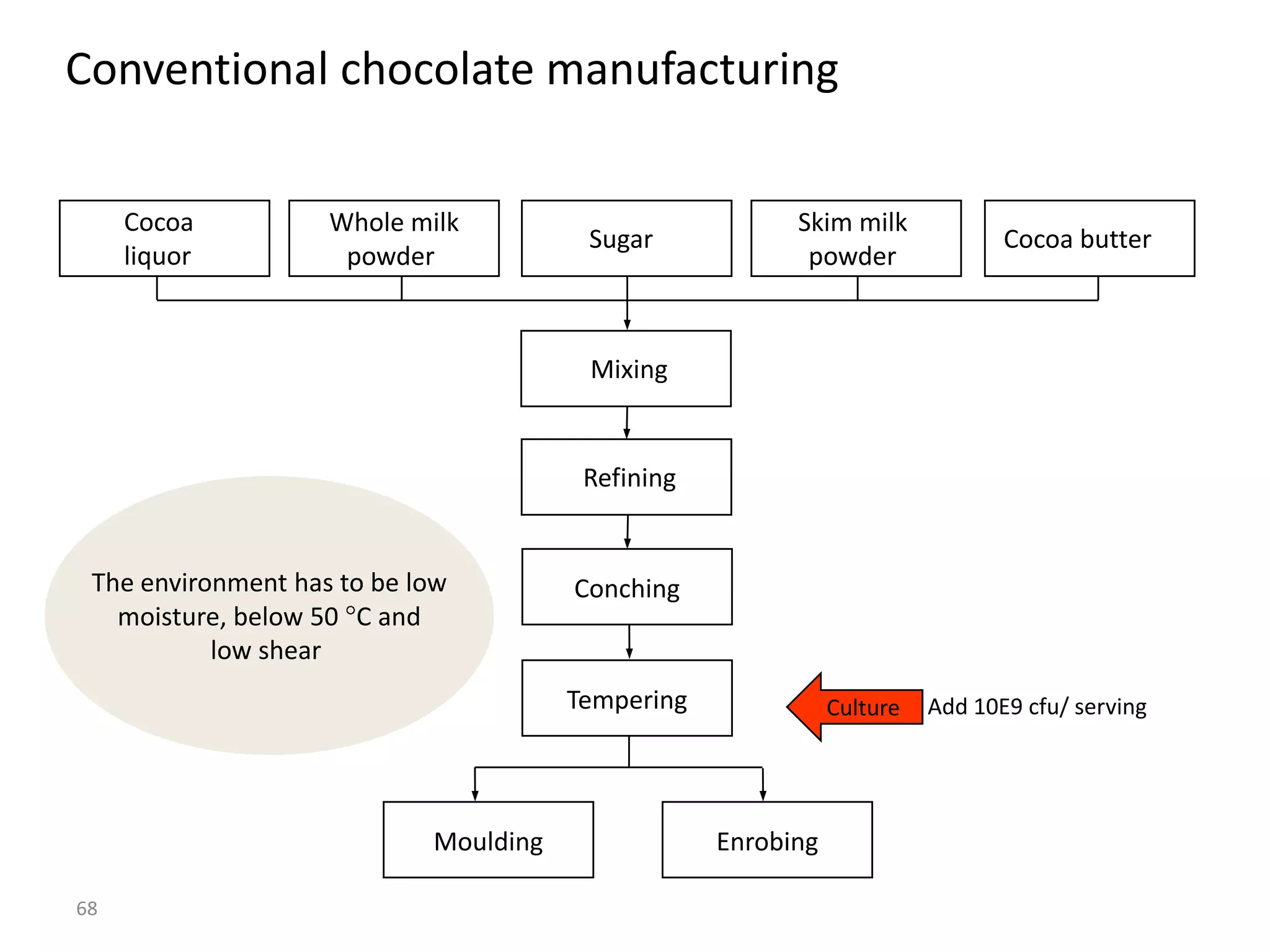

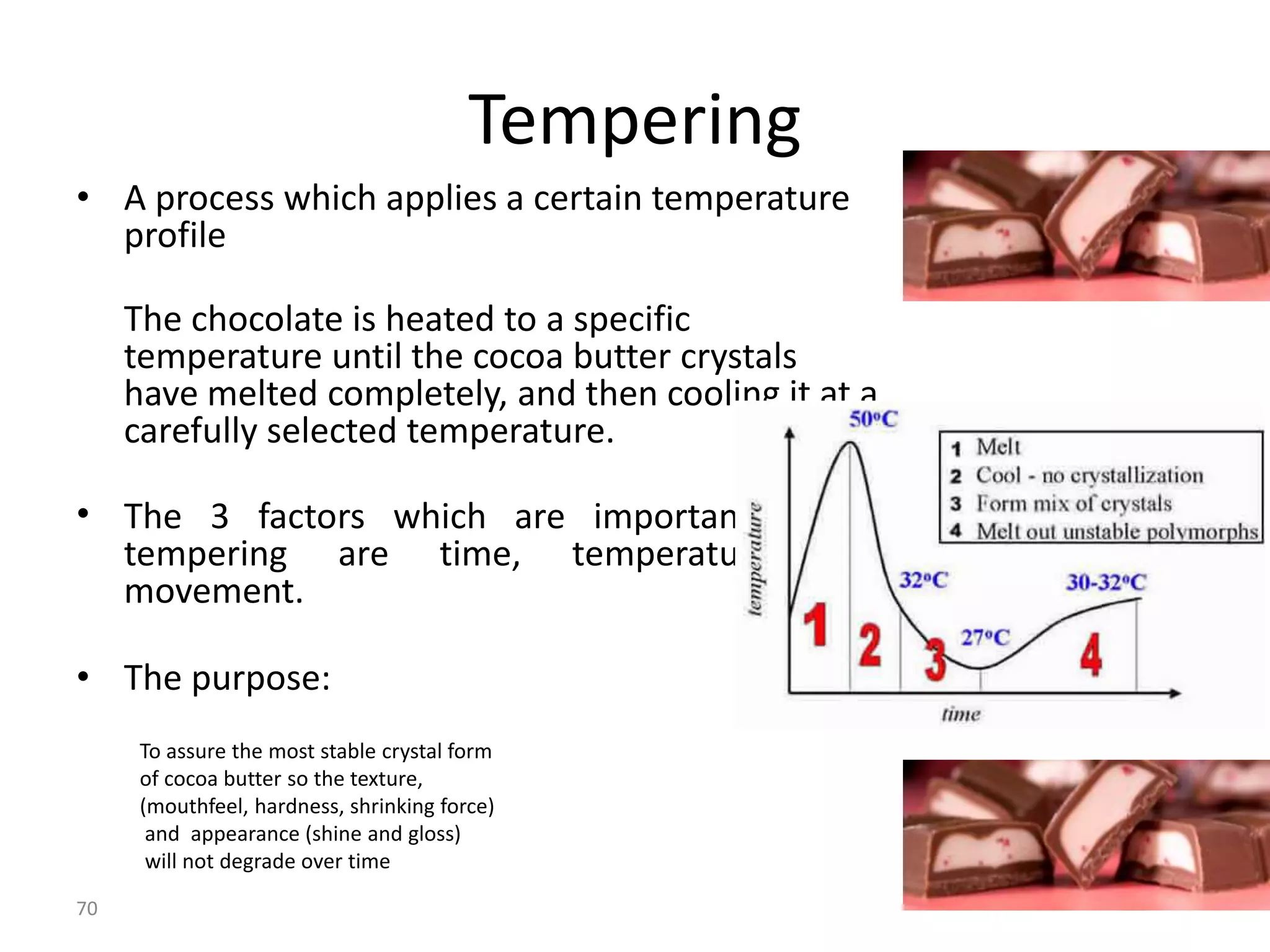

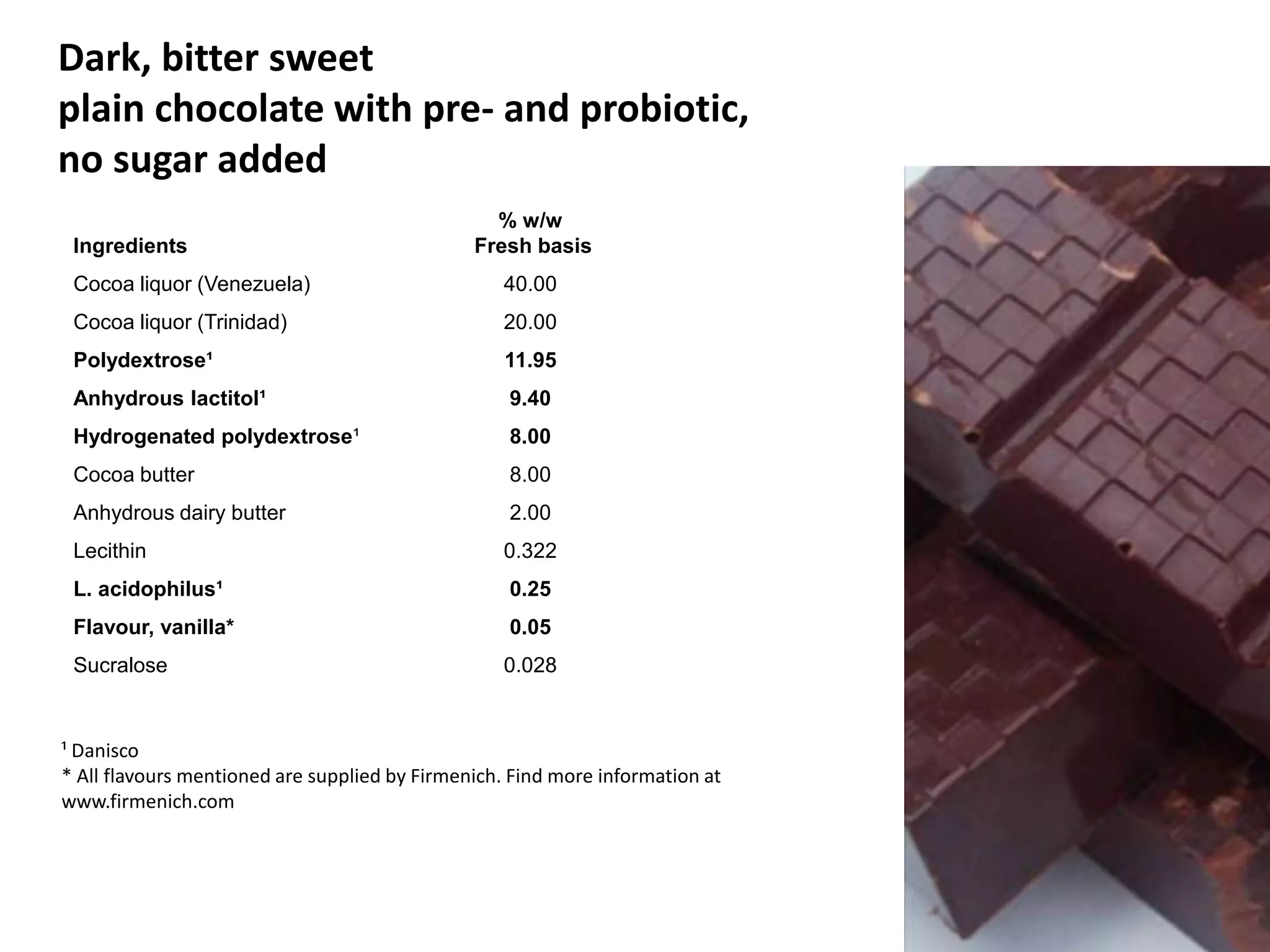

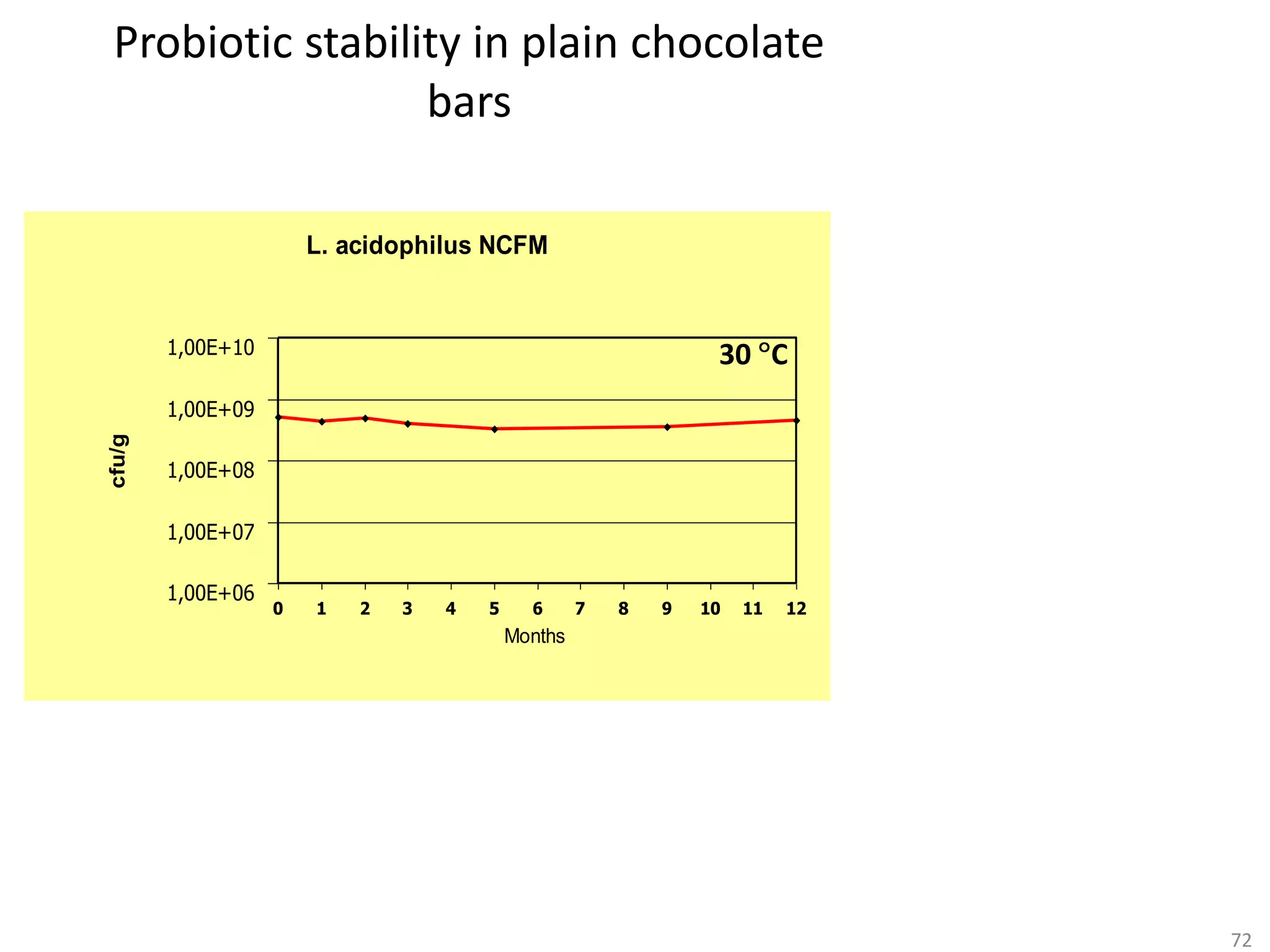

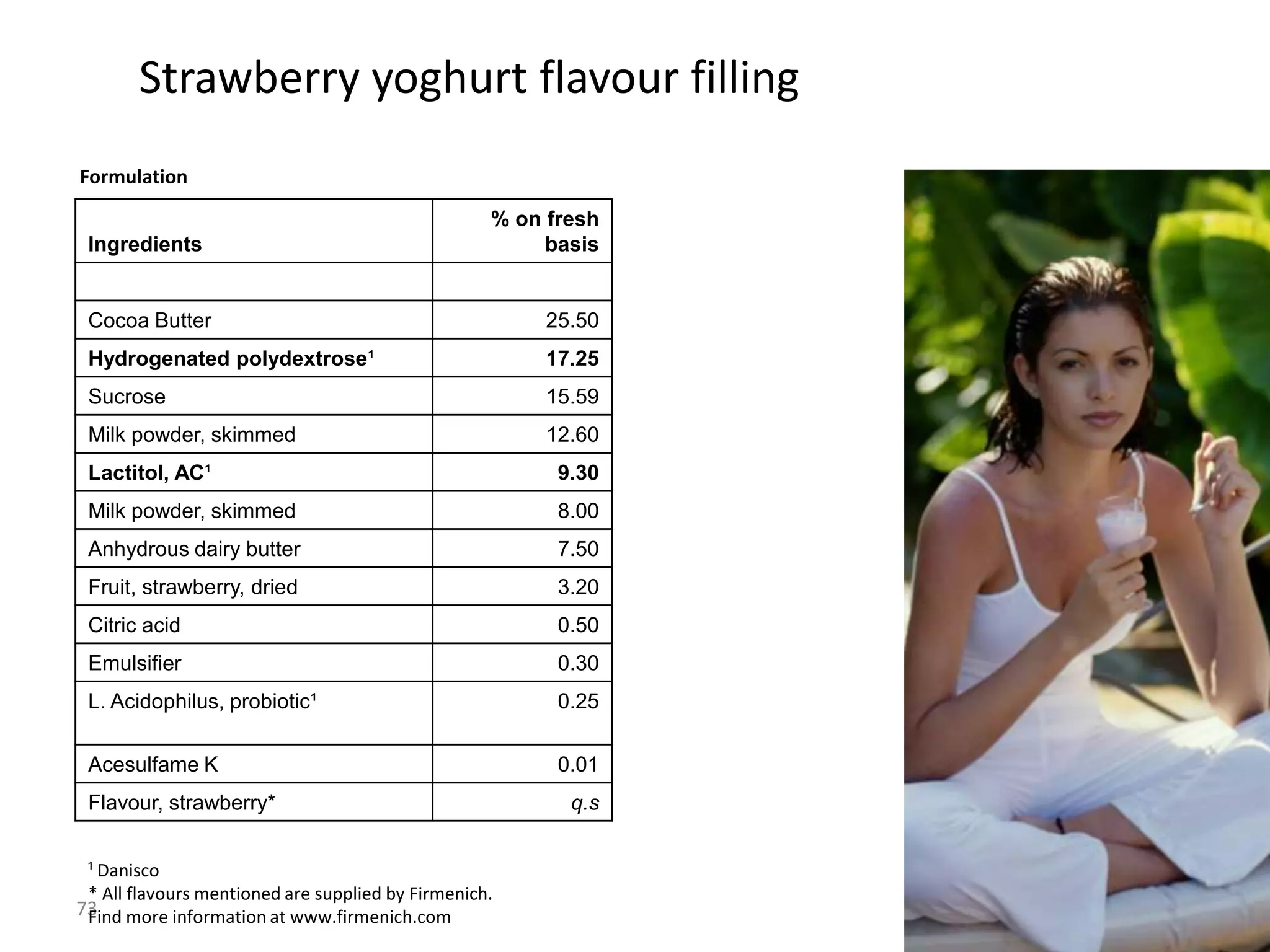

The document discusses global trends in the confectionery market, focusing on health-oriented innovations like reduced sugar and functional chocolates, as well as advanced manufacturing techniques for candy production. It highlights the growing consumer interest in functional foods and 'superjuice' confectionery made from high juice content, while providing insights into crystallization processes and market data. Various sweeteners and their effects on taste and texture of candies are also analyzed, unveiling a shift towards healthier formulations in confectionery products.