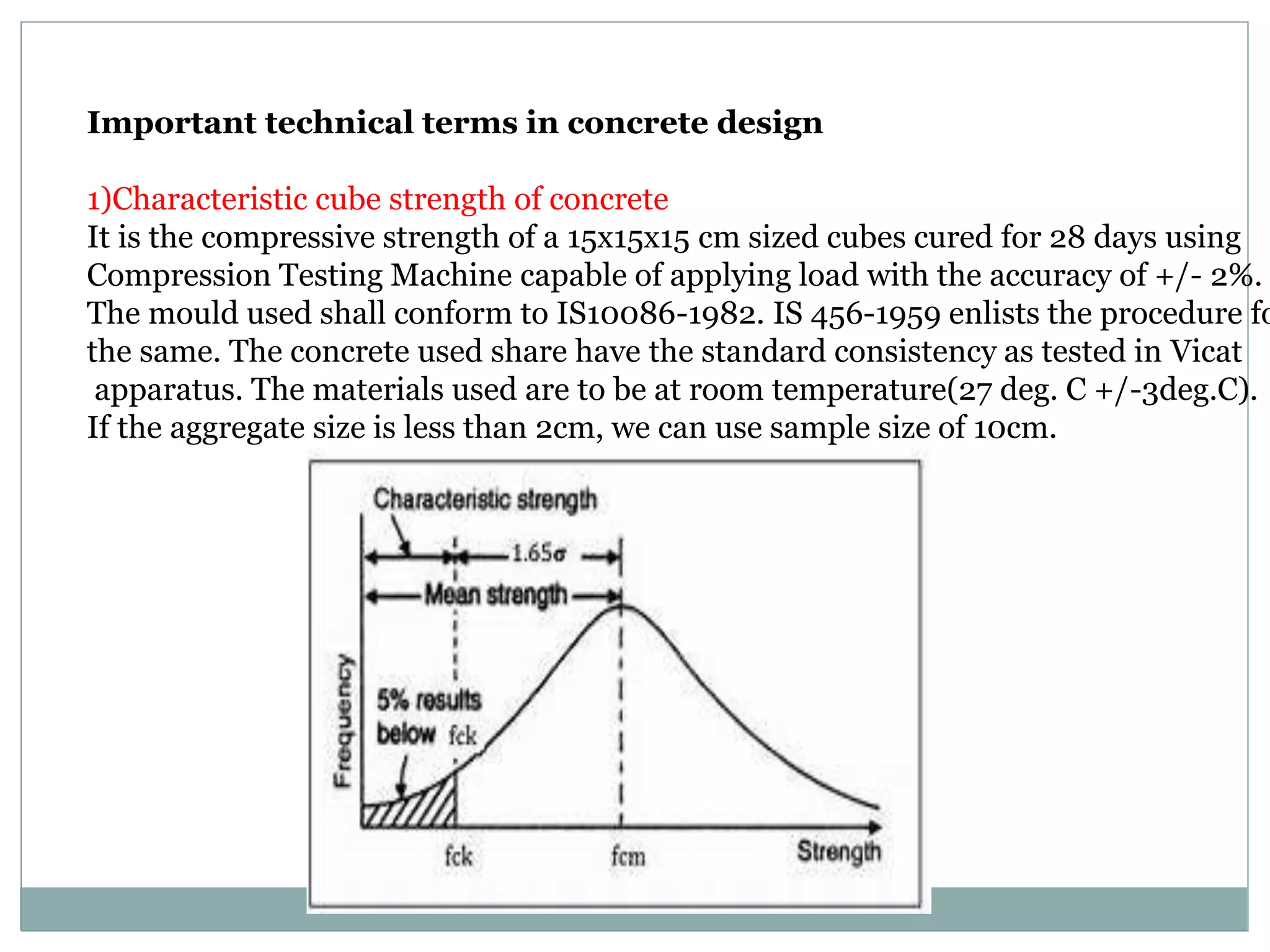

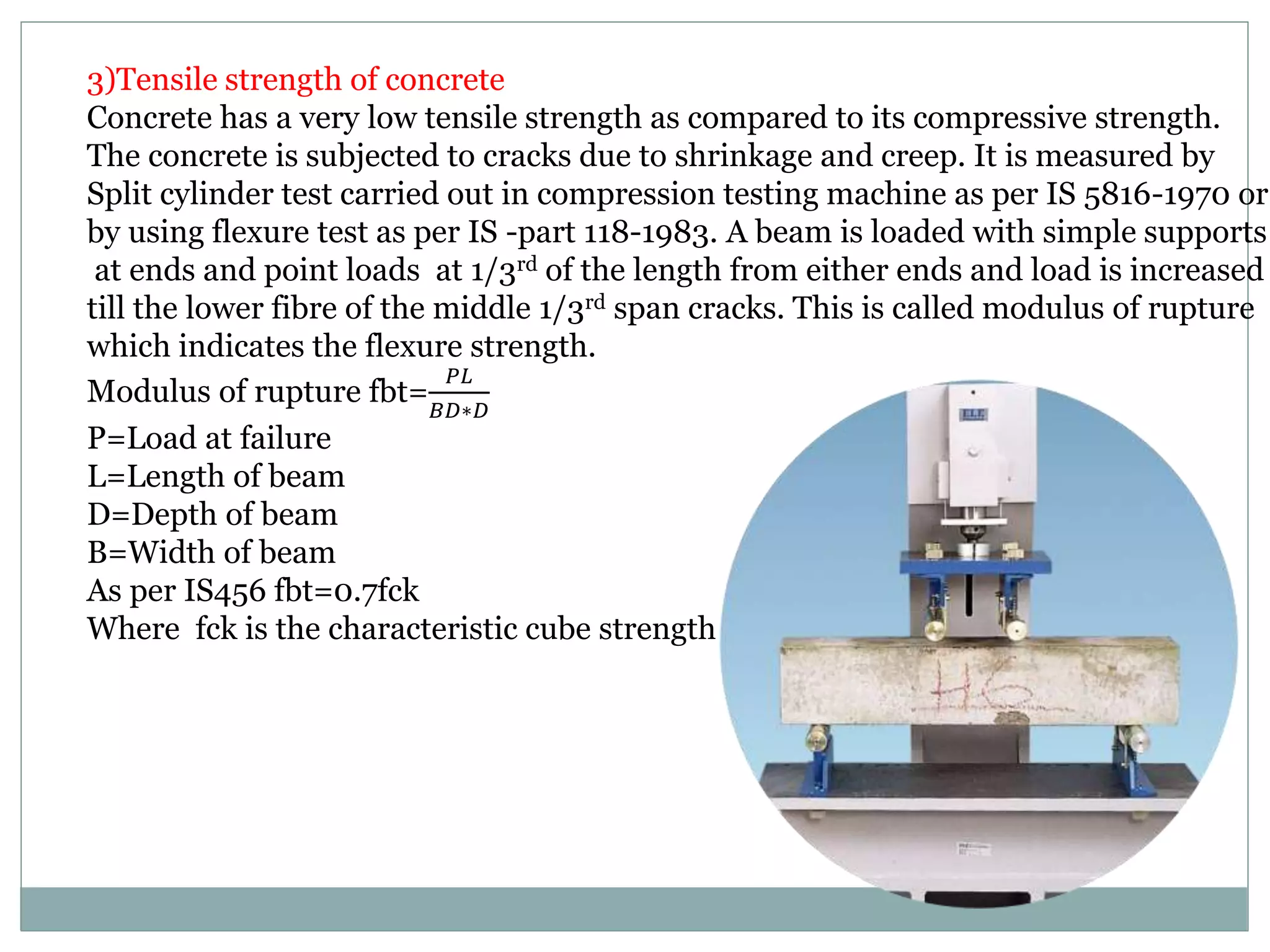

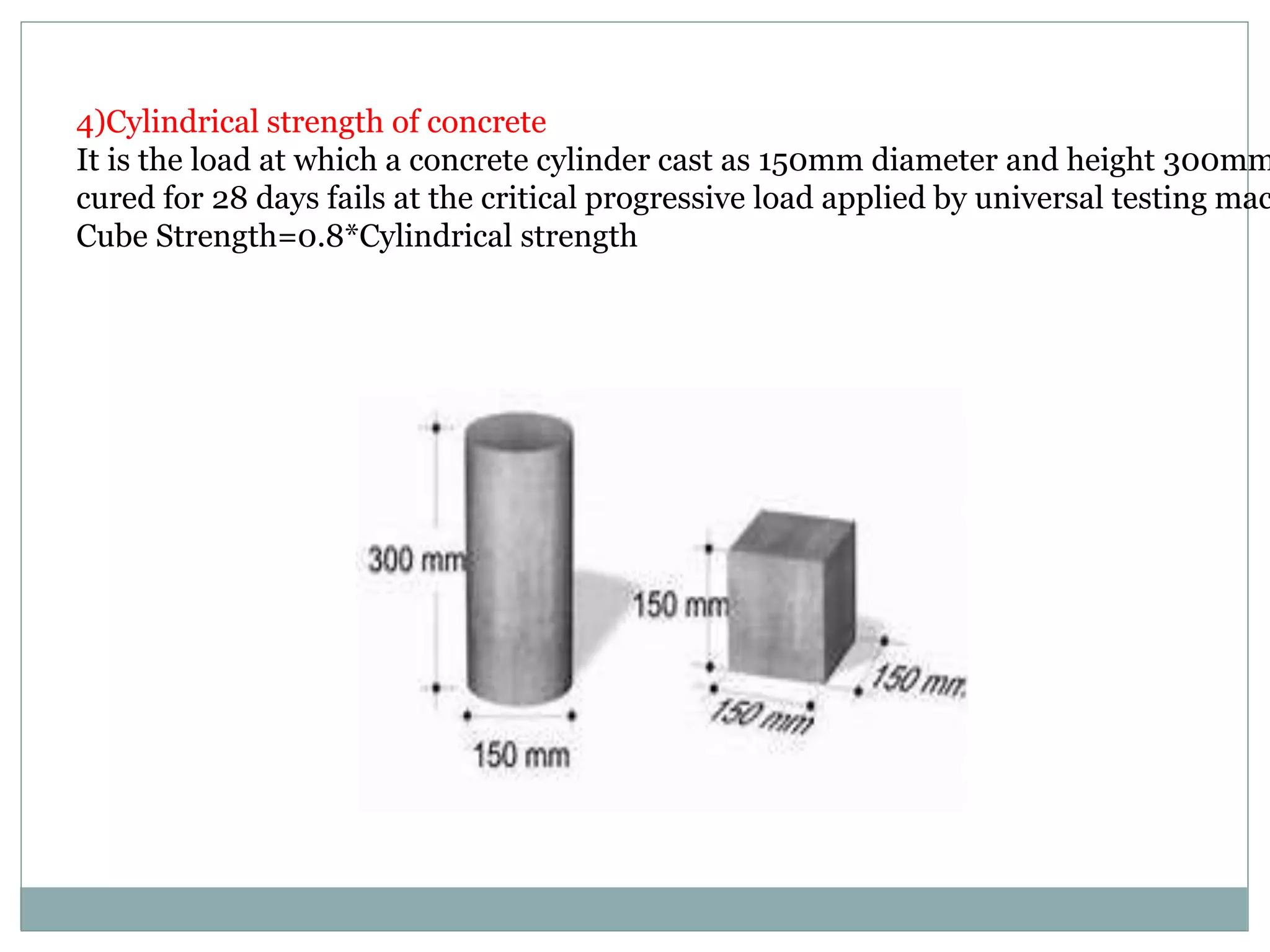

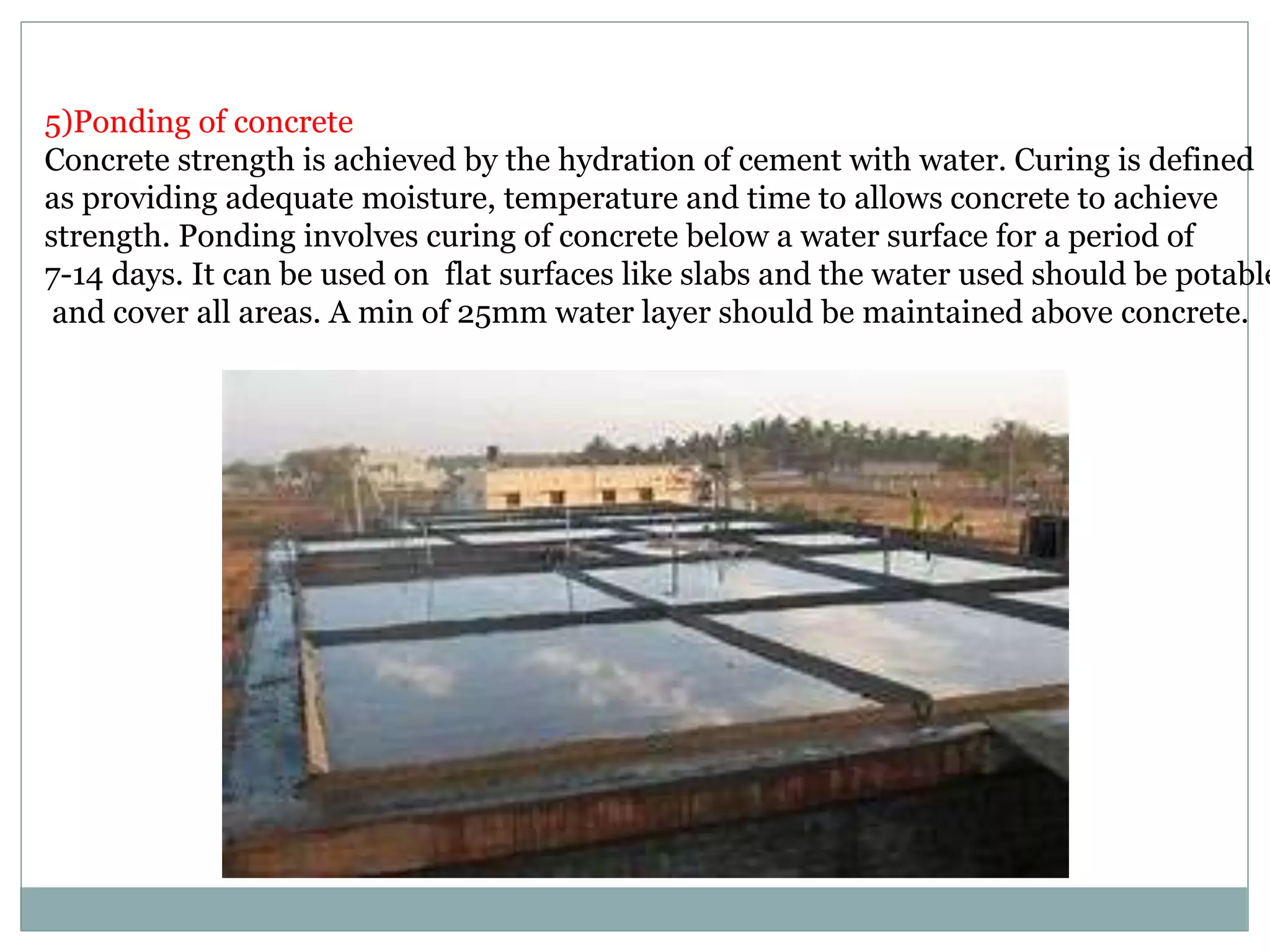

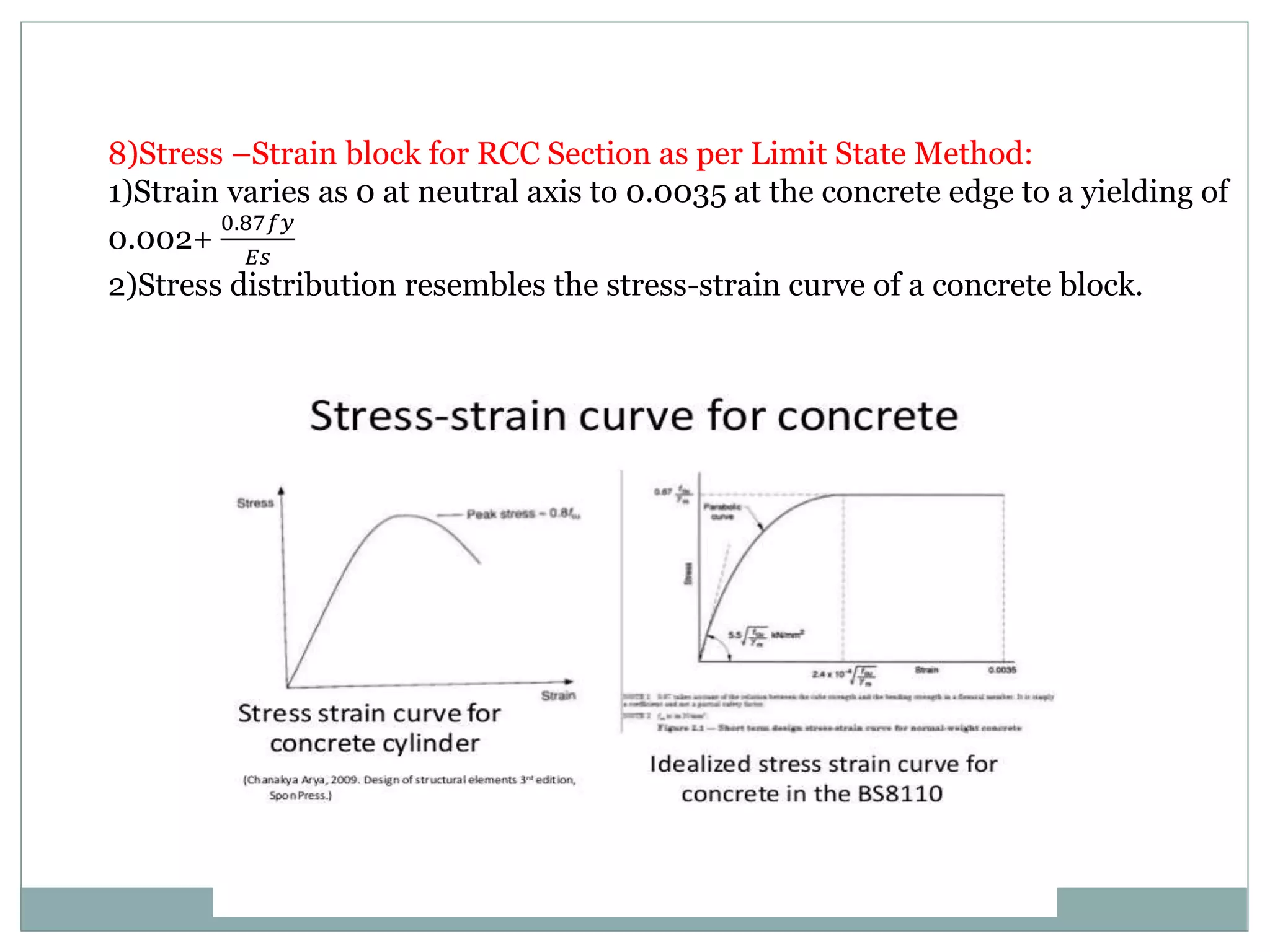

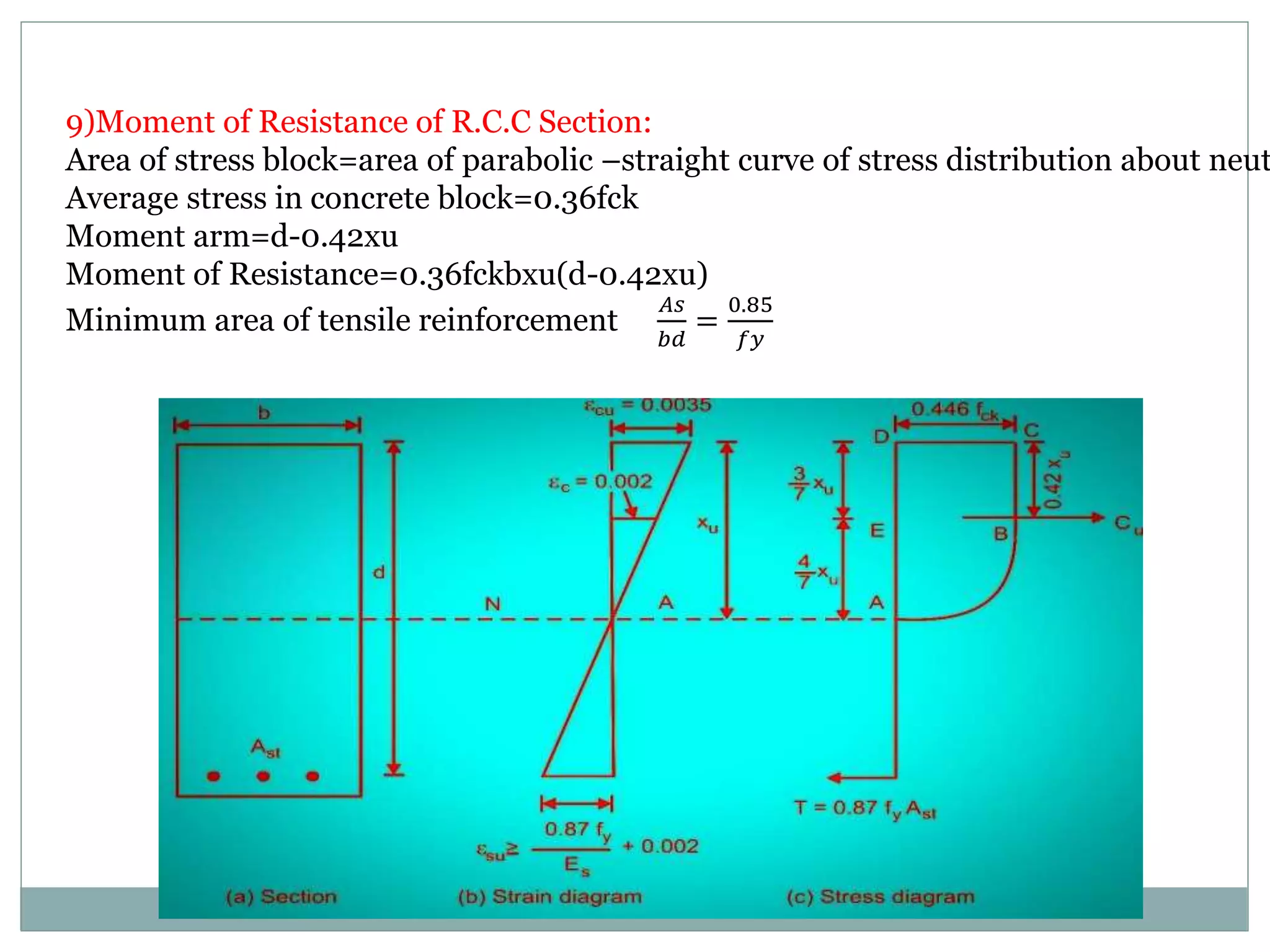

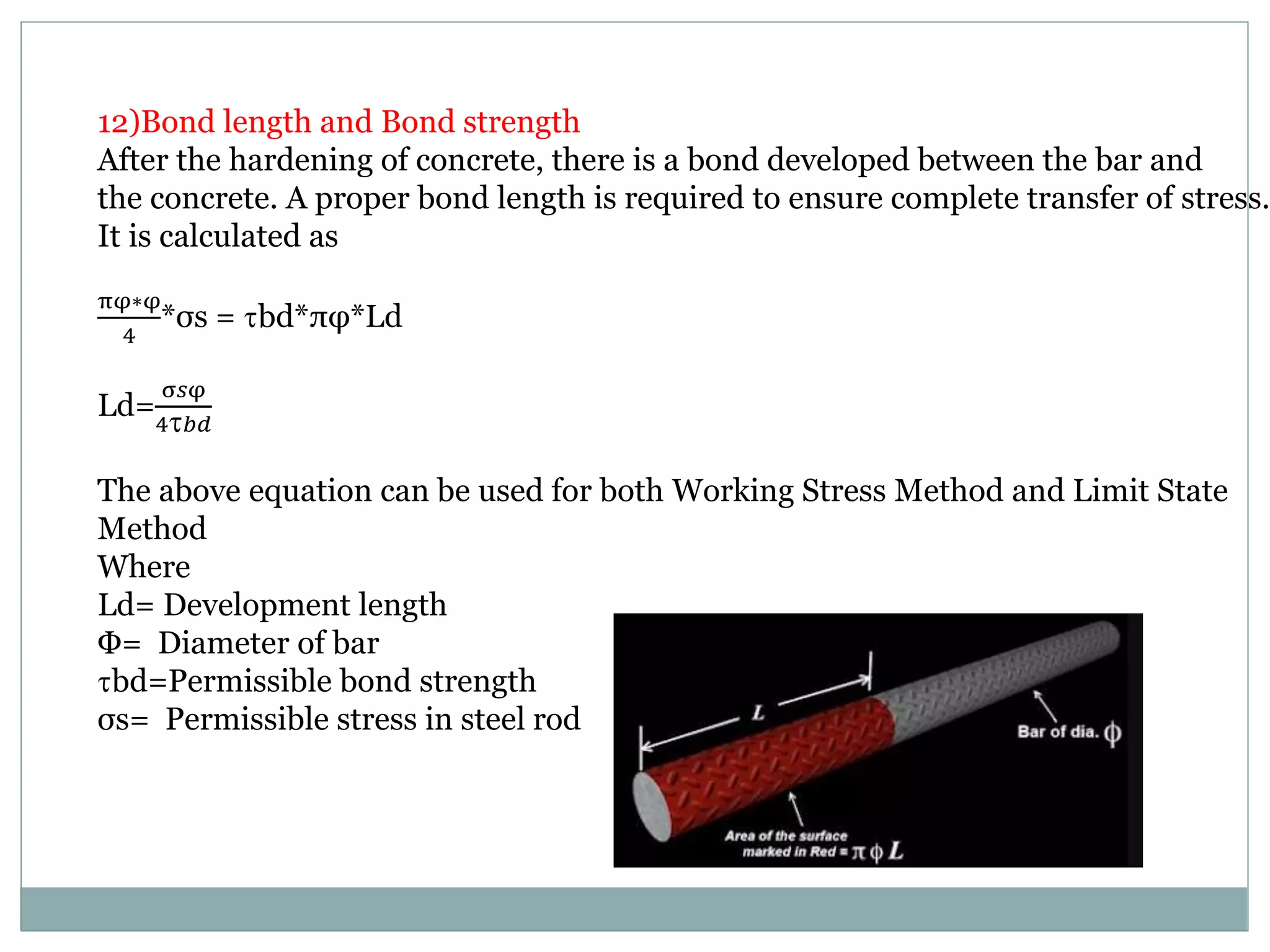

The document outlines essential technical terms in concrete design, including characteristic cube strength, universal testing machines, and tensile strength measurements. Key concepts such as curing methods, effective cover for steel reinforcement, and shear resistance calculations are also discussed, along with the importance of proper bond length and strength between bars and concrete. Additionally, it highlights various standards and procedures that govern concrete testing and structural integrity.