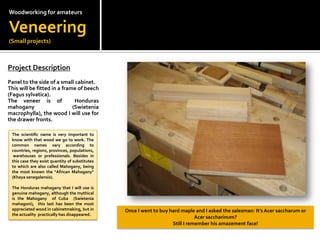

The document provides instructions for veneering a small cabinet panel using Honduras mahogany veneer. It describes preparing the materials, including the mahogany veneer and beech frame. It then outlines the gluing process using a special veneer glue and roller, pressing the panel overnight, and removing excess veneer using chisels and a table saw. The detailed steps and accompanying diagrams provide a concise tutorial for veneering a small woodworking project.