IDJ CV SEPT 2016

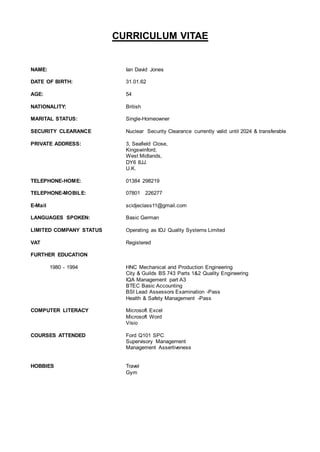

- 1. CURRICULUM VITAE NAME: Ian David Jones DATE OF BIRTH: 31.01.62 AGE: 54 NATIONALITY: British MARITAL STATUS: Single-Homeowner SECURITY CLEARANCE Nuclear Security Clearance currently valid until 2024 & transferable PRIVATE ADDRESS: 3, Seafield Close, Kingswinford, West Midlands, DY6 8JJ. U.K. TELEPHONE-HOME: 01384 298219 TELEPHONE-MOBILE: 07801 226277 E-Mail scidjeclass11@gmail.com LANGUAGES SPOKEN: Basic German LIMITED COMPANY STATUS Operating as IDJ Quality Systems Limited VAT Registered FURTHER EDUCATION 1980 - 1994 HNC Mechanical and Production Engineering City & Guilds BS 743 Parts 1&2 Quality Engineering IQA Management part A3 BTEC Basic Accounting BSI Lead Assessors Examination -Pass Health & Safety Management -Pass COMPUTER LITERACY Microsoft Excel Microsoft Word Visio COURSES ATTENDED Ford Q101 SPC Supervisory Management Management Assertiveness HOBBIES Travel Gym

- 2. EMPLOYMENT HISTORY August 2016 – Present Roxel Rocket Motors Quality Engineer (Security Cleared contract) Responsibilities Business Management System & Process Audits for missile propellant manufacture. Develop Process Audit questionnaire & scoring system (based on VDA 6). Identify shop floor noncompliant practices & advise on permanent corrective actions. Train internal Process Auditors for Business Management System & Process Audits. Implement best practice solutions for propellant manufacture, which includes decanted identification & traceability, consumable shelf life, maintenance activities, in-process inspection & testing, process documentation & document control. February 2016 – August 2016 Cavendish Nuclear Quality Engineer (Security Cleared contract) Responsibilities Managing the supply base for the manufacture of nuclear class / grade 1, 2 & 3 prototype & production components. Assist suppliers in generating Manufacturing Inspection Test Plans (MITP’s). Advise sub- contract sources on nuclear class 1 to 3 requirements .Inspection & Quality Assurance documentation. Advise on Life Time Quality Record (LTQR) document pack evolution & completion. Release of components to AWE site. Witness independent testing, cast transfers, raising NCR’s in the supply base. October 2015 – January 2016 Cavendish Nuclear/ Babcock Marine Technology (Rosyth) Quality Engineer (Security Cleared contract) Responsibilities Assist Project Quality Manager for generating, advising & delivering project quality LTQR submissions to Sellafield, ICG/Bureau Veritas for the Pile Fuel Cladding Silo (PFCS) project. This is a joint venture between Babcock & Bechtel. Overall responsibilities include:- Inspection & test Plan (ITP) creation, advice & approval, supplier development, witnessing & QC/QC component verification / component release. Project internal audits, raw material certification verification, Sellafield ICG liaison, Babcock LTQR review prior to Sellafield ICG submission. December 2012 – September 2015 Babcock Nuclear Services (now trading as Cavendish Nuclear) Quality Engineer (Security Cleared contract) Responsibilities Direct Cavendish Nuclear interface with Atomic Weapons Establishment (AWE) supplier management. Managing the supply base for the manufacture of nuclear class / grade 1, 2 & 3 prototype & production components. Assist suppliers in generating Manufacturing Inspection Test Plans (MITP’s). Advise sub- contract sources on nuclear class 1 to 3 requirement..Inspection & Quality Assurance documentation. Advise on Life Time Quality Record (LTQR) document packs. Release of components to AWE site. Witness independent testing, cast transfers, raising NCR’s in the supply base. April 12 – December 12 Rolls-Royce Nuclear Submarines Quality Specialist (Security Cleared contract) Responsibilities Generate, implement and project manage the introduction of Control Plans for the manufacture of Uranium enriched fuel rods from raw material stage to reactor core assembly for Nuclear Submarines. Advise on Technical Instruction & procedure content , introduce Inspection stamp verification system, gauge R&R

- 3. studies, Quality system upgrade to implement automotive Quality Tools, train shop floor personnel in the use of Control Plans. Identify any opportunities for opportunity for the manufacturing environment. December 11 – April 12 Supplier Project Quality Engineer Chamberlin & Hill (Borg Warner) Responsibilities Project manage machining of raw castings for turbo charger housings. Project manage machine & gauge manufacturers, installation & commissioning of machines & gauges at supply source. Generate & maintain project timing plan, advise on APQP submission, generate PPAP submission timing plan. Advise supplier in the generation of PPAP documentation & subsequent PPAP submissions. Prepare in-process inspection & Work Instruction documentation, Control Plans, packaging specifications, training plans, capacity analysis, gauge R & R’s & establishing special characteristics. July 11 – December 11 Continental Supplier Quality Engineer (Contract) Extended October 2011 Responsibilities Implementation of TS 16949 compliant shop floor inspection & process controls for fuel system plastic injection mouldings. Establish visual, border and dimensional samples for Operators, Inspectors & Final Auditors. Ensure compliance to Control Plan, advise on measurement techniques. Supervise tooling transfer, tooling sample data & historical 8D Problem Solving information to ensure smooth movement of tooling from existing supplier to new supply sources. February 11 – July 11 MIRA Project Quality Manager (Security Cleared contract) Responsibilities Implementation of DEF STAN 05-75 Configuration Management (traceability & serialization management) for Project “P” military vehicles. Implement vehicle manufacturing techniques & systems for improved military vehicle build quality & efficiency. Create processes, procedures and work instructions from design to vehicle assembly. Create autonomous project Quality Manual for MoD audit purposes. Introduce & facilitate (interfacing with MoD) 8D problem solving, Product Change Request process, implement DEF-STAN 05-99 Government Furnished Equipment (GFE) procedures & interface with suppliers of customer owned components. Implement DRACAS (Data Recording And Corrective Action System. Introduction of Supplier development processes & 8D problem resolution. December 10 – January 11 Cummins Turbo Technologies SQA Engineer (New Product Introduction) (contract) Responsibilities Coordinate & provide advice on APQP timing plans and submissions for new product introduction (NPI), improve standard for supplier PPAP and sub-supplier PPAP submissions. Implement enhanced 8D problem solving system for new & existing suppliers. Resolve supplier concerns for prototype components. September 10 – November 10 Ricardo SQA Engineer Mclaren engine launch (contract) Responsibilities Support supply base in UK, Italy, France & The Netherlands for Mclaren engine launch. Provide advice for PPAP submissions from first and second tier suppliers prior to SOP. Support 8D submissions and problem resolution, advise on containment actions and Quality System improvements to support PPAP activity & submission. April 10 – September 10 Vestas Wind Systems PPAP Engineer / Supplier Development (contract) Responsibilities Co-ordination of PPAP submissions for 4 foundries & 15 components in Sweden, Norway & Germany.

- 4. Conduct supplier assessments & subsequent supplier development. Conduct quality system gap analysis against existing supplier quality systems and TS16949 requirements. Advise supply base on gap analysis corrective action plans based on gap analysis results. July 09 – April 10 Babcock Marine Quality Improvement Engineer (Security Cleared contract) Responsibilities Quality Improvement Engineer for Jackal & Coyote military vehicles, preparation for Zephyr new vehicle introduction (Snatch Landrover replacement). Implement vehicle manufacturing techniques & systems for military vehicle manufacture. Conduct supplier assessments, resolve shop floor assembly concerns, liaise with supply base, refurbish torque calibration system, introduction of 8D problem solving tool, resolve paint issues, advise on facilities equipment for vehicle assembly, upgrade & align existing quality system to TS 16949 requirements, improve nonconforming product system. Responsibilities April 09 – June 09 Jaguar / Landrover Vehicles (contract) STA Engineer Responsibilities Programme STA role at Landrover Solihull, covering programme approval of new model launch electrical commodities. Plant 8D and AIMS resolution. Programme management of new part introduction and phased PPAP approval. May 07 – April 09 Jaguar / Landrover Vehicles (contract) STA Engineer Responsibilities Manage 1st tier powertrain and chassis component supply base for UK, Sweden, Poland & Germany. Liaise with OEM, resolve manufacturing issues using 8D problem solving method. Conduct supplier assessments, supplier development, assist supplier in APQP, phased PPAP process & ensure all components are PPAP compliant. Advise & assist suppliers in quality system improvements. Advise on containment & traceability methods, sign-off successful 8D resolution. Components covered include fuel tanks, high pressure fuel lines, knuckles, breather hoses, pedals, gear selectors, engine bearings, differentials, air-boxes and filters. June 06 - May 07 Ford Motor Company (contract) STA Engineer (based in Serbia, Italy, Germany & Slovenia) Responsibilities Co-ordination of facilities, plant & equipment for 5 machining lines. Prepare Serbian & Slovenian foundries for receipt of machining, dimensional, NDT, balancing & painting equipment for solid & ventilated brake disc manufacture. Civil engineering timing plan ( floors, roofing, cladding, walls, utilities - air, gas, electricity, extraction). Provide technical assistance to suppliers of equipment in Germany & Italy -vertical lathes, drilling, balancing, NDT, dimensional & painting. Installation & commissioning of equipment. Support equipment manufacturers in meeting timing plan deadlines. Oversee equipment sub-suppliers. Manage CCAR document defining all quality system improvements required for run@rate & volume production (TS 16949 requirements). Advise supplier on CCAR resolution & quality system improvements. Report to Ford Cologne on CCAR progress & concern resolution. Prepare supplier for transfer of Jaguar fuel tank production - pressings, welding, leak testing & sample preparation ready for PPAP submission. Nov 05 - June 06 Ogihara Europe Limited (contract) SQA Development Engineer Responsibilities Assist in setting up the SQA Department to control all externally sourced pressings, sub-assemblies (previously produced in-house) & raw materials. Develop supplier assessment audit questionnaire & rating system in accordance with TS 16949, conduct supplier assessments for new sources of supply. Develop supplier quality assurance manual & tooling transfer process in conjunction with the purchasing function. Implement supplier concern & 8D problem solving process. Ensure suppliers provide PPAP submissions, also technically assist suppliers with level 3 PPAP submissions, audit corrective actions & 8D resolution.

- 5. Develop processes for Quality & Logistics related concerns & re-sourcing of Ogihara Europe Limited owned tooling. Aug 05 - Nov 05 Hampson Aerospace Machining (contract) Senior Quality Engineer Responsibilities Undertake AS9100 (aerospace quality system standard) gap analysis against existing quality system. Identify major systemic issues & propose corrective action improvements for existing quality system registration. Resolve major & minor non conformances for the chemical processing initial assessment for NADCAP approval (SAE Aerospace Standard AS7003). Interface with SNECMA for System Quality Assurance Plan submission & approval. Liaise with Rolls-Royce (Derby) supplier development personnel for quality system improvements & NADCAP approval progress. Prepare NDT operations for NADCAP November scheduled audit. Major customers:- Rolls-Royce, SNECMA & MTU Jun 05 - Aug 05 Marshall Specialist Vehicles (contract) Project Quality Engineer Responsibilities Interpretation of MOD DEF Standards to identify design input criteria for replacement Ministry of Defence military support vehicle. Establish project gateway criteria from supplier assessment to prototype validation. Supplier assessments carried out against TS 16949 criteria. Jan 05 - Jun 05 GKN Autostructures (contract) SQA Engineer Responsibilities Supplier technical assistance for PPAP submissions, investigation of shop floor rejections for bought -out components, organise containments via 3rd party inspection agencies, resolve technical problems with suppliers & ensure continuity of supply, advise suppliers (UK & Europe) in completing problem solving documentation (8D principal), conduct system, site surveys & process audits in accordance to TS 16949, conduct control plan audits, witness tooling trials for prototype & volume production establishing capability & conformance, assist in developing & documenting supplier process parameters & advising on inspection techniques, frequencies & equipment. Aug 04 - Dec 04 Omron automotive electronics (contract) Quality Systems Engineer - TS 16949 implementation Responsibilities Conversion of QS 9000 to TS 16949. Undertake Initial gap analysis & then Implement product design & development processes from product concept to product validation & completed product. Improve the following quality system elements:- product / process monitoring & measurement, nonconforming product & rework data, product & process change control, predictive & preventive maintenance, product traceability, laboratory test procedures (in accordance with IOS 17025), document control system identification & structure, purchasing & supplier evaluation, control plans & special characteristics, measuring equipment intervals. TS 16949 registration anticipated March 2005. NOTE. Omron was not previously product design responsible. Dec 03 - Aug 04 Jonathan Lee (contract) Supplier Development Engineer Responsibilities Acting on behalf of General Motors / Fiat / Saab in an SQA role to stabilise & improve processes at automotive first tier suppliers to ensure product conformity & continuity of supply. Responsible for PPAP submissions, control plans, capability studies, MSA, process & system audits. Develop robust & user-friendly quality systems that enhance the effectiveness of the quality system & product range. This role involves hands-on experience with the product & quality system infrastructure. An in-depth knowledge of TS 16949 was necessary in this role, which included undertaking ISO 9001 / QS 9000 & TS 16949 gap analysis &

- 6. implementation program's at 1st tier suppliers to General Motors in Austria & Sweden. Conversant with GM "Drill Deep & Wide" problem solving process. Sep 03 - Dec 03 Commercial Insurance & Pension Brokers ISO 9000 2000 Advisor (Part-Time) Responsibilities Upgrade & refurbish the company’s existing ISO 9002 Quality System to the ISO 9000 2000 year specification for year end 2003. ISO 9001 2000 registration achieved December 2003 Jan 02 - Sep 03 Rolls-Royce & Bentley Motor Cars, Crewe (contract) TS 16949 System Advisor - Business Process Development Responsibilities Auditing the company’s existing ISO 9001 Quality Management System against the requirements of the new automotive standard TS 16949. Conduct gap analysis & present findings to senior management. Implement all manufacturing & customer requirement elements of TS 16949. These elements include Special Characteristics, Control Plans (prototype & volume), process controls, calibration & shop floor documentation - including Control of Documents system. Prepare all functions in the company for initial TS 16949 registration to be carried out by TUV. Implementation also includes all product & process design related elements of TS 16949 - Design inputs to design validation. Produce & present training/awareness material to all functions. All corrective actions & subsequent implementation to meet company wide project plan. Note. TS 16949 registration achieved September 2003 Sep 00 - Dec 01 Rolls-Royce & Bentley Motor Cars, Crewe (contract) ISO 9001Quality Systems Advisor Design & Engineering Responsibilities This position involves the application of ISO 9001Quality Management Systems from product concept to product validation stage in preparation for volume manufacture. Advise on all aspects of ISO 9001. Refurbish and rationalise Quality System. Align ISO 9001 to product emergence process (BPEP). Produce and advise on procedure / task instruction generation for new model / product projects (new medium size Bentley) and product emergence. Implement Internal audit system, produce training material, process mapping and train Quality Systems Advisors. Carry out procedure and working process content analysis and initiate continuous improvement. Advise on generation of "electronic" Quality Systems manual. Liaise with Corporate Quality / Accreditation bodies and organize preparations for external assessments. Aug 00 - Sep 00 Macworth Tools Limited Consultant Responsibilities Preparation of procedures, work instructions and Internal Audit programme for ISO 9002 assessment. This company manufactures bespoke progression and press tools. Processes include CATIA and CNC machining. Software control was a fundamental element in certification. ISO 9001 2000 registration achieved September 2003 Note. BSI recommendation for this role. Jun 98 - Aug 00 Landrover Vehicles Plant Manager ISO 9001 Systems Responsibilities Advise, implement and rationalise ISO 9001 Quality Management Systems plant wide for Body In White, Paint, Vehicle Assembly, Logistics and Manufacturing Engineering. Implementation of internal quality audit programme and audit scoring system. Introduce scrap reduction measures. Align quality system infra- structure with BMW - Dingolfing. Co-ordinate continuous improvement programmes. Resolution of supplier major non-compliances. Represent Landrover Vehicles at Rover Group and liaise with external accreditation bodies.

- 7. Jul 96 - Jun 98 Rover Group Powertrain (contract) BS EN ISO 9001 Quality Systems Advisor Responsibilities To refurbish and rationalise the ISO 9001 management system which contains 240 Quality Assurance manuals on 3 sites for 8000 employees (Rover Landrover MG). Represent Power Train at Rover Group. Develop audit programme and train Audit Department, produce and facilitate Quality System training material, advise on all aspects of ISO 9001, produce and implement procedures, reduce documentation, resolve major non-compliances, liaise with BMW manufacturing plants to develop Process Review systems, and associated documentation (BMW South Africa, U.S.A, Austria and Germany). A ‘hands on’ involvement plays a significant contribution in this role Jun 96 - Dec 96 C.S.S. Shearing Ltd Consultant Responsibilities Implement and register C.S.S. Shearing Ltd to ISO 9002. This company specialises in precision sheared blanks. ISO 9002 registration achieved December 96, Accreditation body BSI. Mar 96 - Jun 96 Inalfa U.K. Ltd (contract) Quality Management Systems Advisor Responsibilities To implement a quality system compatible to the requirements of Renault, Rover and ISO 9001.Inalfa is a major supplier to the automotive industry. ISO 9001 registered May 96, Accreditation body BSI Jan 95 - Mar 96 Air Tube Conveyors (division of Metsec plc) Works Director Responsibilities 36 employees Oversee purchasing and price negotiations. Stores ISO 9001 Implementation Investors in People Health & Safety Manufacture Implement MRP system Implement flexi-time clocking system. Reduce employee absenteeism. Premises maintenance Recruitment Mar 94 - Dec 94 Metsec Industries (U.S.A.) Group Quality Control Manager Responsibilities To implement ISO 9001 for the design, manufacture, installation and servicing of pneumatic tube systems for two sites in California and North Carolina. Experience includes liaison with the underwriters laboratory (UL). Jan 89- Mar 94 Metsec plc Group Quality Control Manager Responsibilities To implement, maintain, and upgrade ISO 9000 quality management systems for 11 UK based divisions 2 German, 2 U.S.A. and 1 Australian division. During this period six companies were awarded ISO 9002 registration and one ISO 9001 registration. The ISO 9001 registration was for design, manufacture and installation of the ‘Fast Track’ construction method for commercial and residential buildings. This construction method was also awarded Wimpey Laboratories (WIMLAS) certification. The role also included:- Liaison with BSI, WIMLAS (construction) and MOD for routine surveillance visits Total quality management training Recruitment of personnel Preparation of control plans for specific contracts Training of quality control personnel for statistical techniques Training personnel in the use of measuring equipment (including calibration)

- 8. Audit training Customer and supplier liaison Oct 87- Feb 89 Metal Sections (division of Metsec plc) Quality Control Manager Responsibilities To implement a quality control system compatible to ISO 9002 for the Custom Roll Forming division of Metal Sections. Processes include the ERW welding process. Profiles include symmetrical / non-symmetrical welded profiles, and profiles of a light and heavy duty nature. Other processes included presswork and welded assemblies. Hands on experience with a variety of measuring equipment was necessary in this role along with a good understanding of subjective standards .ISO 9002 approval was achieved in June 1988.