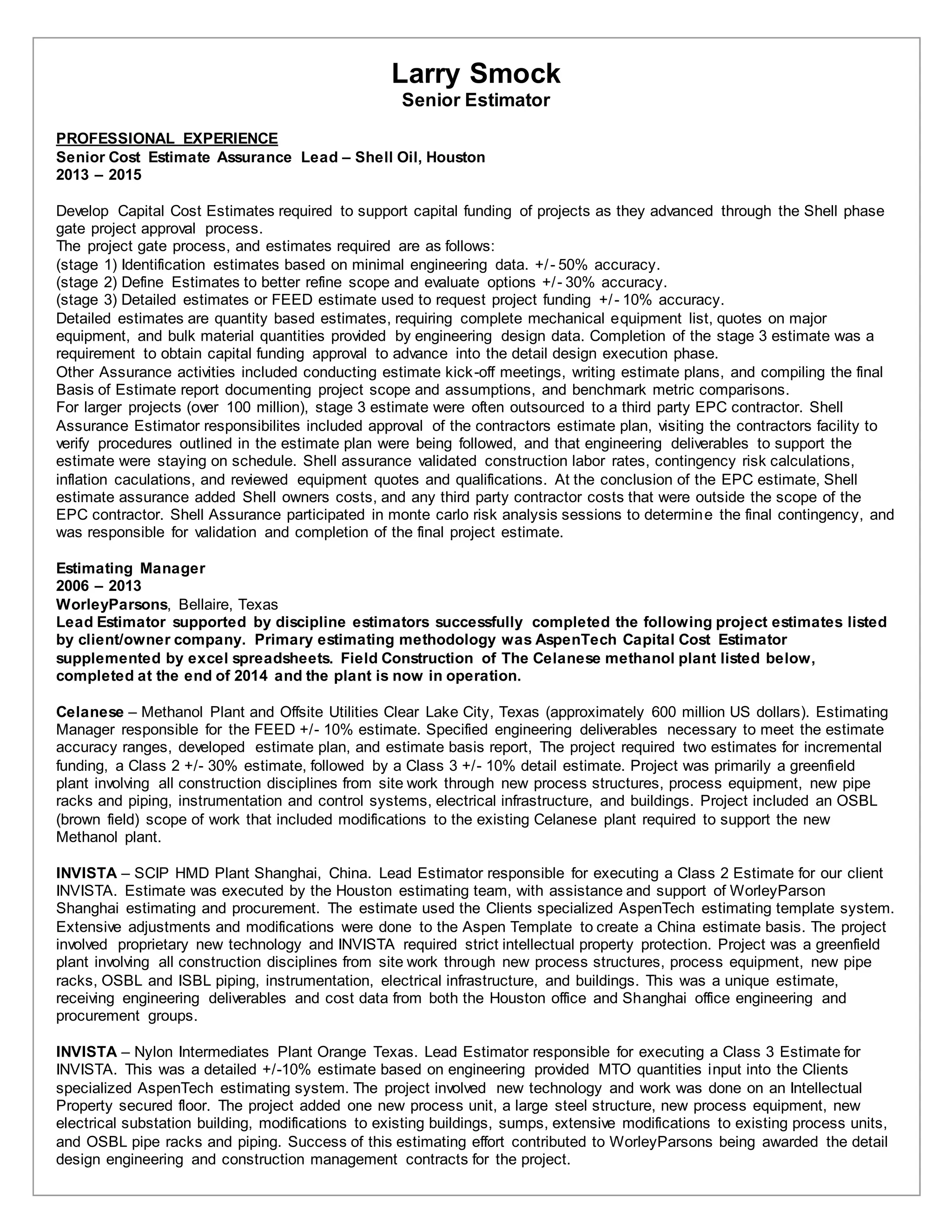

Larry Smock has over 30 years of experience in cost estimating for major capital projects in the oil and gas industry. He has specialized expertise in using Aspen Tech estimating software. As a senior estimator, he developed capital cost estimates for multi-billion dollar projects to support funding approval. Responsibilities included verifying engineering data, reviewing equipment quotes, and validating risk and contingency calculations. He also has experience managing teams of estimators and producing estimates at various stages of project definition.