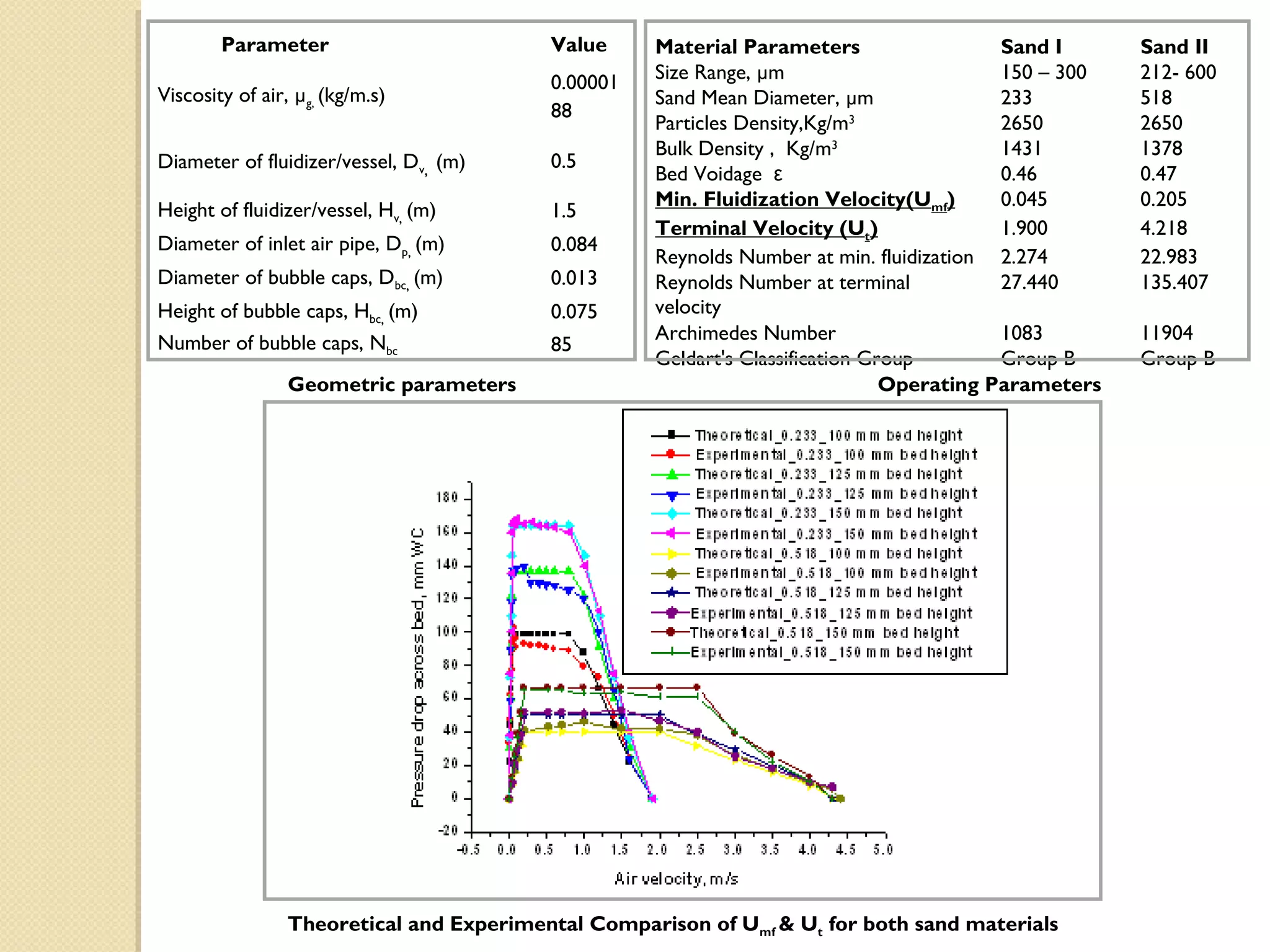

This document summarizes a study on the hydrodynamic behavior of a cold model bubbling fluidized bed system using bubble caps. Key findings include:

1) Experiments were conducted on a laboratory scale cold model fluidized bed system to study hydrodynamic parameters like minimum fluidization velocity (Umf) and terminal velocity (Ut) that are difficult to measure under actual high temperature/pressure conditions.

2) Parameters measured included Umf, Ut, and bubble behavior for two types of sand (Sand I and Sand II) used as bed material. Theoretical predictions of Umf and Ut using established equations were also compared to experimental values.

3) Results provide insights into the fundamental hydrodynamics of

![Min. Fluidization Velocity

The pressure drop through fixed beds of has been correlated by Ergun[13] using the

equation: 2

∆P (1 − ε m ) 2 µ g uo 1 − ε m ρ g uo

g c = 150 + 1.75 3 ………………….. (1)

L 3

εm (φ s d p )

2

εm φsd p

The minimum fluidization occurs when

(drag force by upward moving gas ) = (weight of particles)

or (∆P bed) (Area bed) = (Volume bed) (Fraction of solids) (specific weight of solids)

g

or ∆P. Abed = ( Abed Lmf )(1 − ε mf ) ( ρ s − ρ g ) ………………….. (2)

gc

Umf , the superficial velocity of gas at minimum fluidization conditions, is found by

combining eqn. (1) and eqn.(2):

1.75 d p umf ρ g 150(1 − ε mf ) d p umf ρ g d p ρ g ( ρ s − ρ g ) g

2 3

3

+ = ..........................(3)

φsε mf µg φs ε mf

2 3 µ µg

2

g

The equation (3) can also be written as:

1

d p u mf ρ g d p ρg (ρs − ρg )g

3 2

= ( 33.7 ) + 0.0408

2

Re mf = − 33.7 …………………..(4)

µg

µg

2

](https://image.slidesharecdn.com/hydrodynamicstudybfbieeebangalore-121029160303-phpapp01/75/Hydrodynamic-study-bfb-ieee_bangalore-9-2048.jpg)

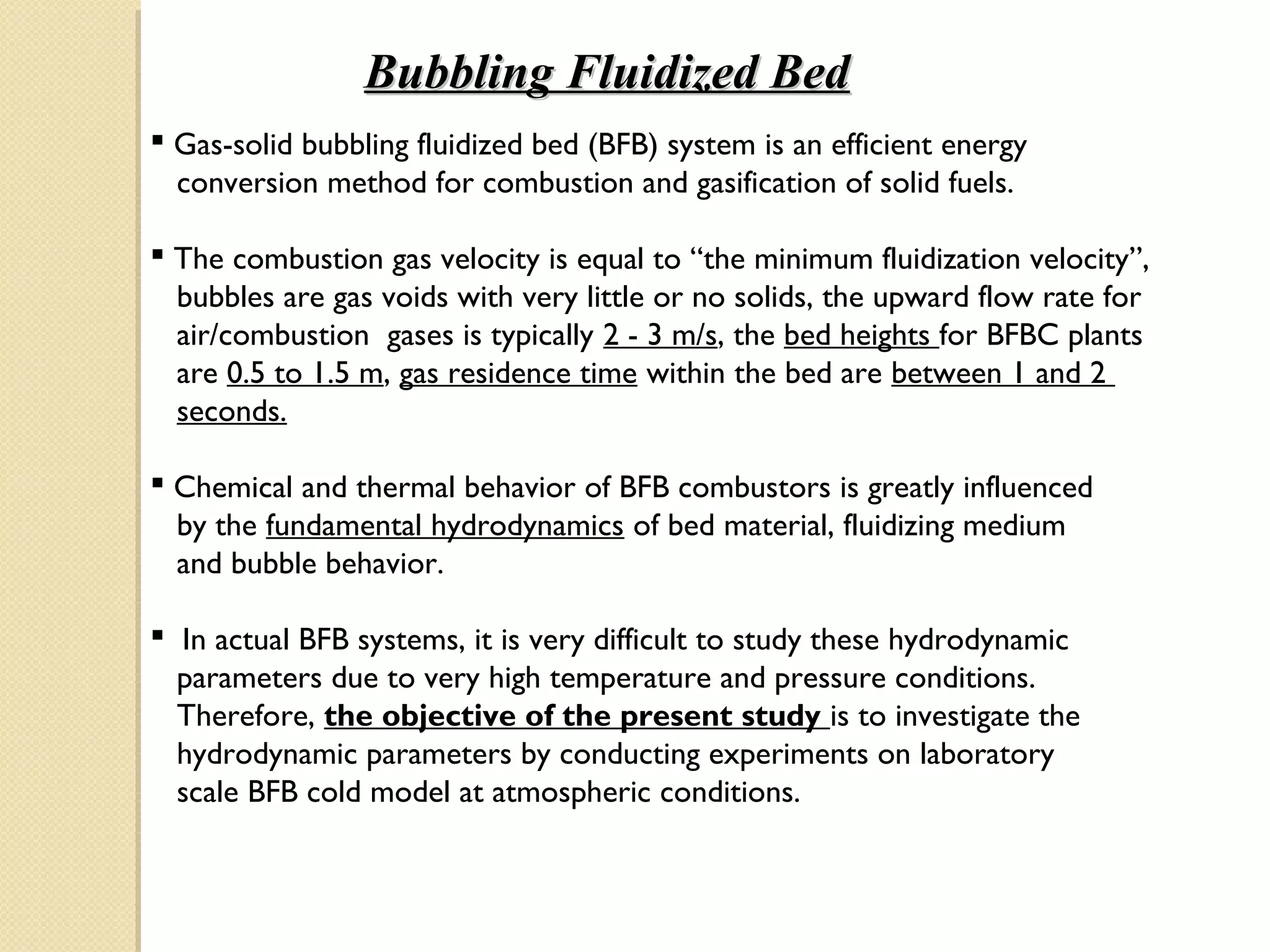

![Terminal Velocity of Sand Particles

The gas flow rate through a fluidized bed is limited on one hand by u mf and on the other by entrainment of

solids by the gas. When entrainment occurs these solids must be recycled or replaced by fresh material to

maintain steady-state operations. This upper limit to the gas flow rate is approximated by the terminal or

free-fall velocity of the particles [14], which can be estimated from fluid mechanics by:

4 gd p ( ρs − ρg ) 2

1

ut = …..…(5)

3ρg C d

Where Cd is the experimentally determined drag coefficient.

10

C d , spherical = 12

, 0.4<Rep<500 …..…(6)

Re p

The expression for terminal velocity [14] is also given as

below:

( )

1

4 ρ s − ρ g 2 d p2 2

U t , spherical = d , 0.4<Rep<500 …..…(7)

225 ρ gµ g p

Terminal velocity(non-spherical),Ut’=Kt .Ut (spherical) ……... (8)

The correlation factor Kt is obtained by [15] :

ϕ

K t = 0.843 log 10 For Re <0.2, …... (9)

0.065

4( ρp − ρg ) gd v

0. 5

Kt = For Re<1000, …... (10)

3ρg ( 5.31 −4.88 ϕ)

Experimentally, terminal velocity of type sand I and sand II is find out by visual observations i.e. when the inlet air

flow rate is increased beyond the flow rate at which entrainment of sand particles is started, the pressure drop across

the bed is decreasing and at certain stage this pressure drop almost tend to zero when there is almost negligible sand

material in the bed. At this stage, terminal velocity for both sand materials is obtained.](https://image.slidesharecdn.com/hydrodynamicstudybfbieeebangalore-121029160303-phpapp01/75/Hydrodynamic-study-bfb-ieee_bangalore-10-2048.jpg)

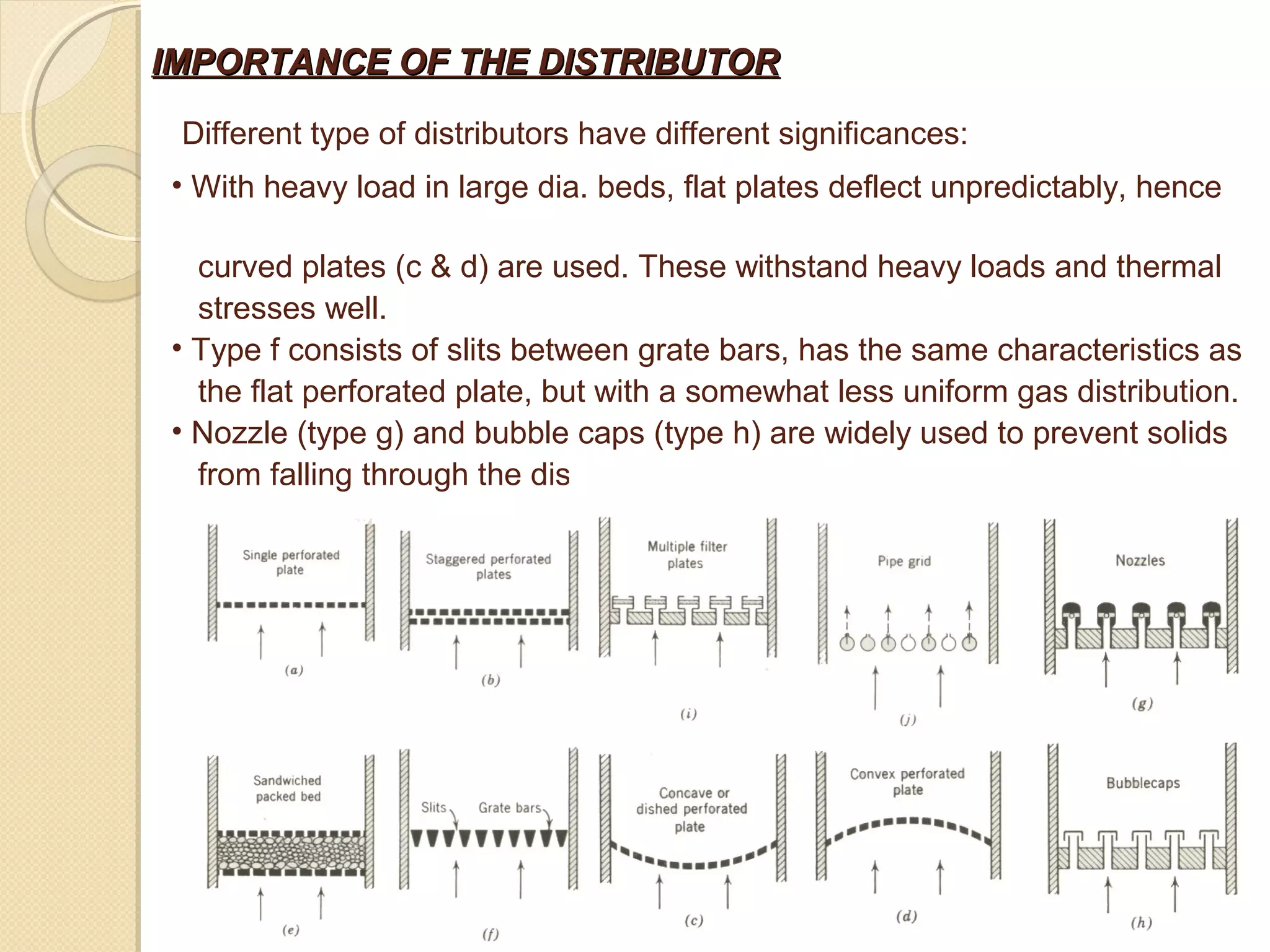

![Bubble Behavior

A. Minimum Bubbling Velocity (Umb):

Fluidized systems with a small density difference between fluid and particles expand uniformly, while those

with a large density difference are generally unstable and produce bubbling. The lowest gas velocity at which

bubbling occurs is called the minimum bubbling velocity. There are two correlations are presented to find u mb:

1) The correlation to find umb is given by Broadhurst and Becker [16] :

d pU mb ρ g Ar

Re mb = = …………… (11)

µg 0.22

9.8 × 104 Ar − 0.82 ρ s + 35.4

ρ

g

2) Geldart[17] suggested a correlation for minimum bubbling velocity as:

U mb = K mb ×d p …………… (12)

Where Kmb is a constant whose value is 100 in cgs system. Davison & Harrison observed that the interval

between minimum bubbling velocity and minimum fluidization velocity represents the stable uniform

fluidization, which shrinks rapidly as the size of the particles increases.

B. Bubble size

There are several methods of observing bubbles in gas-solid fluidized beds:

1) Simple methods like visual observation if vessel is transparent,

2) still or cine photography,

3) using probes,

4) using two dimensional beds,

5) X-ray observation,

6) observation of particle movement,

7) observation of single isolated bubble.](https://image.slidesharecdn.com/hydrodynamicstudybfbieeebangalore-121029160303-phpapp01/75/Hydrodynamic-study-bfb-ieee_bangalore-12-2048.jpg)

![The major advance in the study of fluid beds came with the investigations of single, isolated bubbles. The

Davison model remains useful as a first approximation. An isolated bubble in a fluid bed takes the form of an

indented sphere. The leading spherical surface is called the roof and the apex is the nose. The solids filling the

indentation are transported with the bubble for natural sand from 100 to 600 µm the wake fraction was from

0.22 to 0.28. The rise in velocity of an isolated bubble [18] depends on its size, given as:

1

U b = 0.79 gVb 2 = 0.711 gDb …………… (13)

C. Bubble growth and coalescence

After detachment from the distributor, bubbles interact as they rise in the bed. The coalescence of a pair of

bubbles has been investigated by Clift and Grace [19,20] and by Toei and Matsuno[21]. There are several

characteristics of the coalescence process. The leading bubble spreads horizontally as the trailing bubble

elongates and accelerates into the wake of the leader. The volume of two bubbles increases by 20-30%

during coalescence, followed by a 10% decrease during consolidation after wake entry, giving a net volume

increase of 10-20%. There is increased gas flow through the emulsion phase between the bubbles. The

following relation finds the maximum size:

( )

0. 4

Dbed 2 U 0 − U mf

D b∞ = 2.35 …………… (14)

g

Bubble growth and splitting lead to a distribution of bubble size in the bed. Agarwal used a population balance to calculate the

bubble distribution. Three correlations have been found to be reliable for mean bubble size.

1) Mori & Wen [22] use the initial and maximum bubble sizes with first order growth rate (as it is the

most popular equation for calculation). With distributor plate having Bubble cap,

Db ( H ) = Db∞ − ( Db∞ − Db 0 ) exp − 0.3H

.............(15)

Dbed

](https://image.slidesharecdn.com/hydrodynamicstudybfbieeebangalore-121029160303-phpapp01/75/Hydrodynamic-study-bfb-ieee_bangalore-13-2048.jpg)

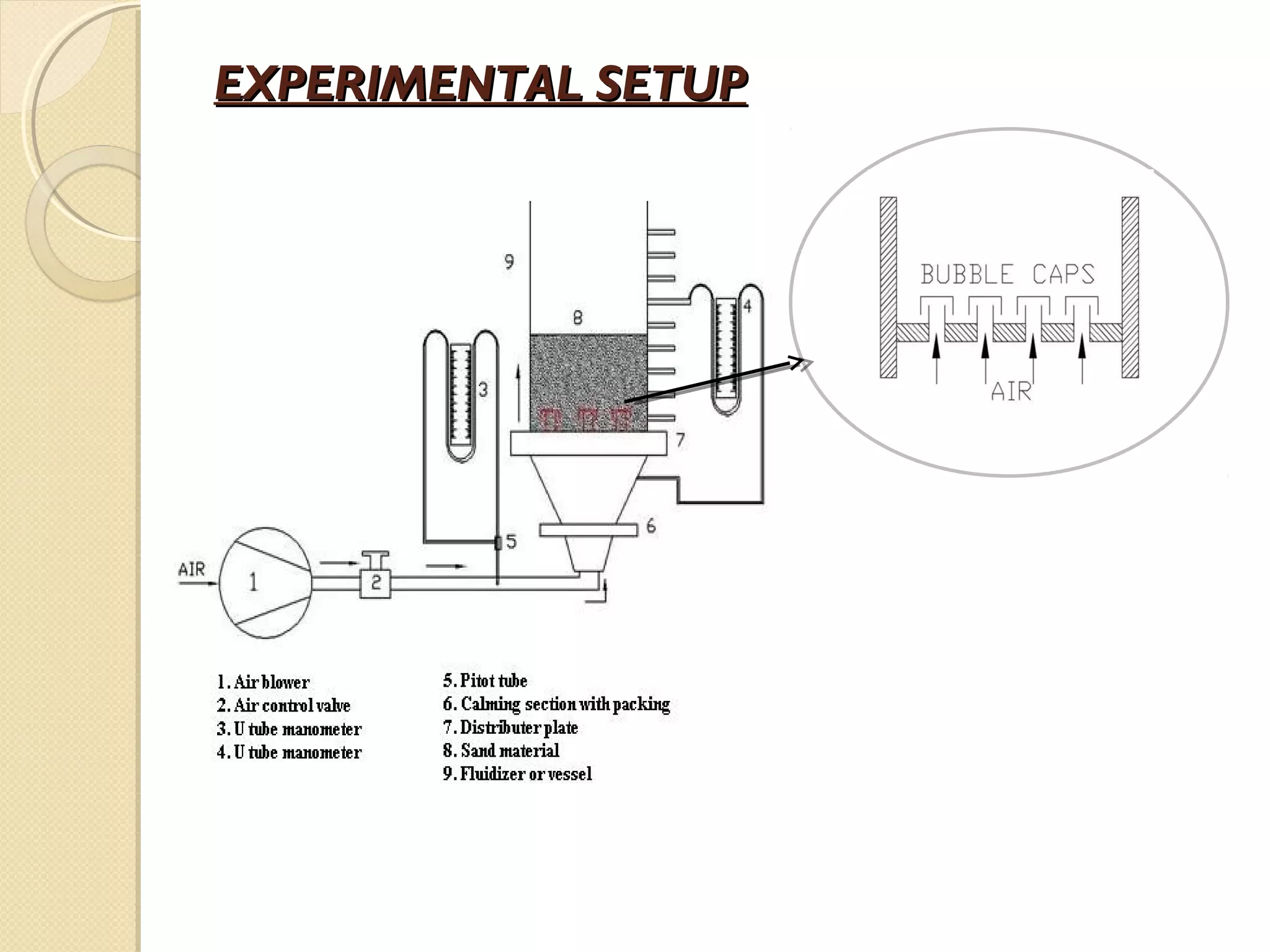

![2) Darton [23] has suggested another correlation for bubble size and the same is represented as:

0 .8

0.54(u −u mf ) Abed

0 .4

H + 4

N or

Db ( H ) = …………….. (16)

0 .2

g

3) Rowe [24] proposed a correlation to predict bubble size in a gas-solid fluidized bed (when size is

not

restricted by the column dimension) as:

(U 0 −U mf ) 12 ( H + H 0 ) 3 4

Db ( H ) = 1

…………….. (17)

g 4

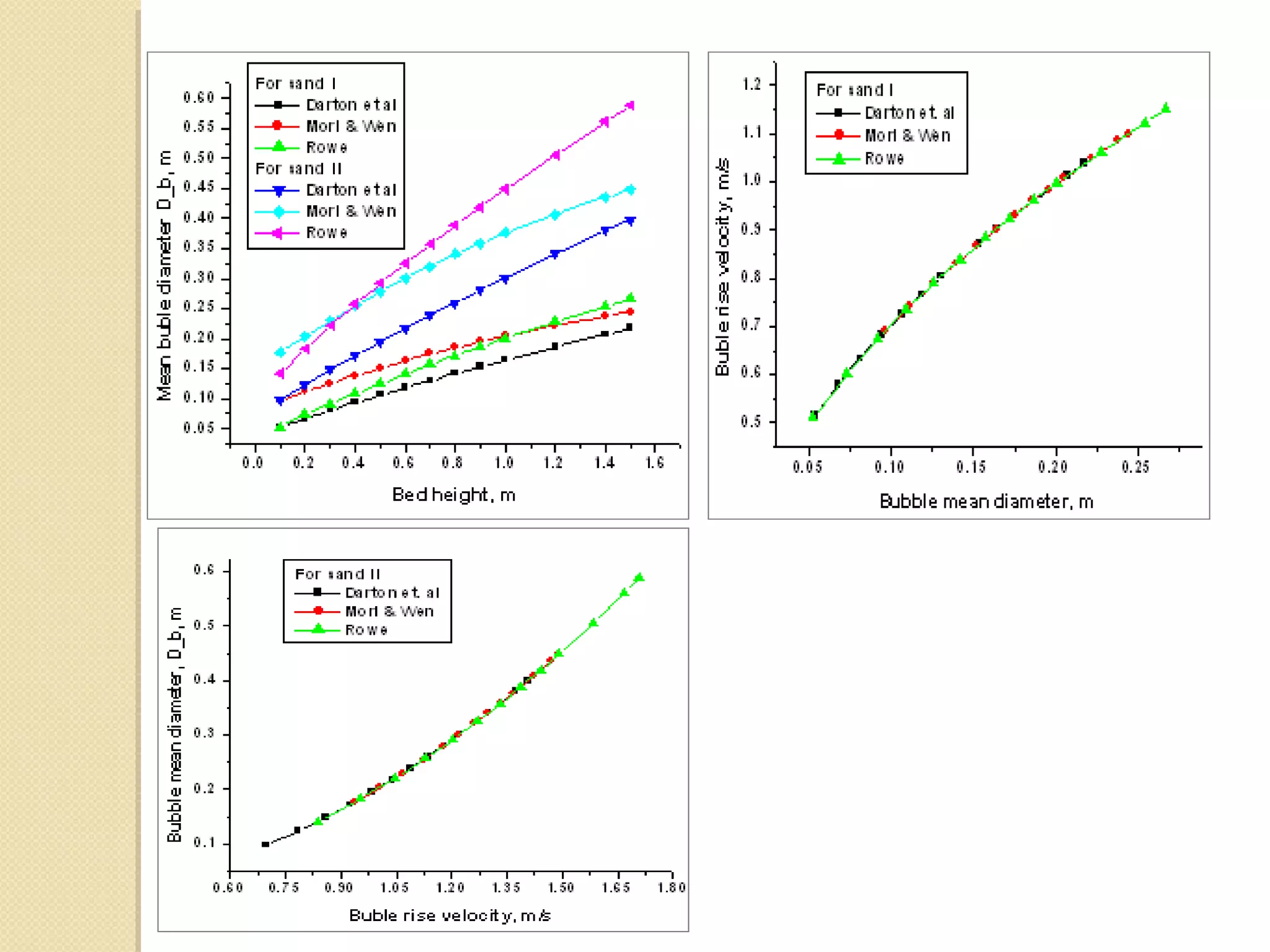

Table . Comparisons between bubble size for both sand materials:

Ref. Darton [23] Mori [22] Rowe [24]

Sand I Sand II Sand I Sand II Sand I Sand II

Uo 0.158 0.718 - - 0.158 0.718

Umf 0.045 0.205 0.045 0.205 0.045 0.205

H 0.1-1.5 0.1-1.5 0.1-1.5 0.1-1.5 0.1-1.5 0.1-1.5

Dbed 0.5 0.5 0.5 0.5 0.5 0.5

Abed 0.196 0.196 0.196 0.196 0.196 0.196

Nor 85 85 85 85 85 85

Dmax. 0.357 0.654 0.357 0.654 0.357 0.654

Dmin. 0.080 0.147 0.080 0.147 0.080 0.147

Db 0.053-0.217 0.098-0.399 0.096-0.244 0.176-0.448 0.052-0.267 0.142-0.588

Ub 0.514-1.038 0.697-1.406 0.691-1.101 0.936-1.491 0.509-1.151 0.838-1.708](https://image.slidesharecdn.com/hydrodynamicstudybfbieeebangalore-121029160303-phpapp01/75/Hydrodynamic-study-bfb-ieee_bangalore-14-2048.jpg)