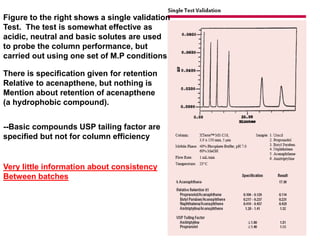

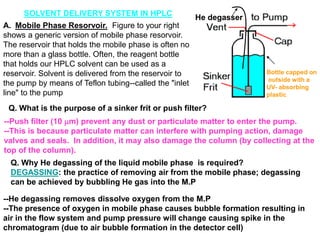

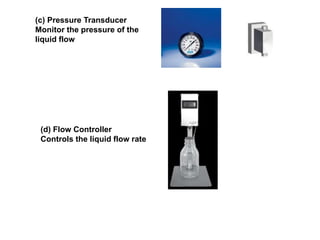

The document provides an extensive overview of High Performance Liquid Chromatography (HPLC) instrumentation and techniques, detailing the setup and functioning of components such as pumps, solvent reservoirs, and injectors. Key topics include the importance of degassing mobile phases, the operational mechanics of various pump types, and the specifications for optimal column packing materials. It also discusses the advantages of automated systems and injection methods, along with considerations for material choice in HPLC manufacturing.

![Zero Dead Volume (ZDV)

There is really no way of

knowing whether the tubing

is butting together or not, or

if the tubing is butting in the

center of the union. [Figure

to the right] demonstrates

this difficulty.

A true zero dead-volume union, or ZDV, would

connect two pieces of tubing without any dead-

volume, or mixing chamber, between the tubing.

The tubing would butt perfectly together as shown

to the right. A connection of this type is difficult,

If not impossible to achieve.](https://image.slidesharecdn.com/hplcbasics-240330112339-03e0d08d/85/HPLC-Instrumentation-Techniques_basics-ppt-24-320.jpg)