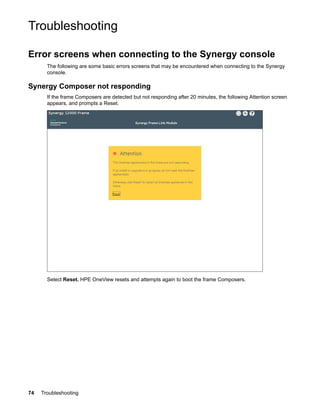

This document provides instructions for installing the HPE Synergy 12000 Frame. It describes site requirements including power, cooling, space, temperature and grounding. It also covers unpacking components, identifying parts, installing the frame in a rack, installing modules, and cabling. Safety warnings are provided throughout regarding lifting, grounding, power disconnection and servicing only as instructed.