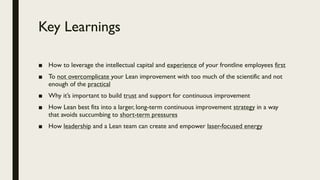

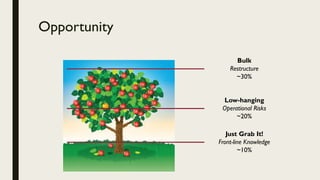

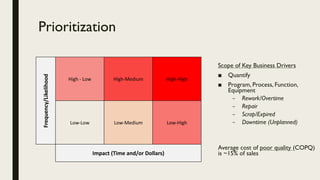

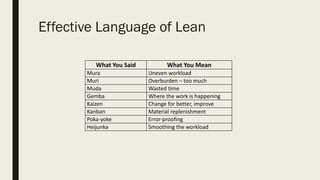

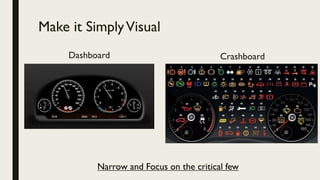

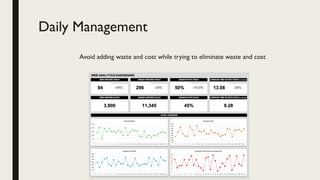

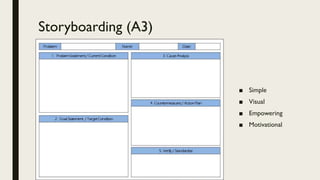

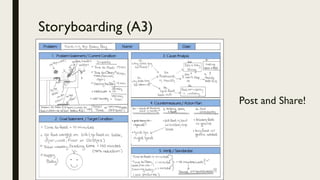

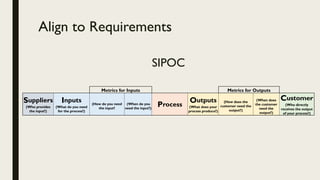

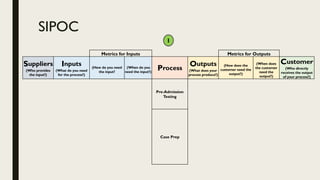

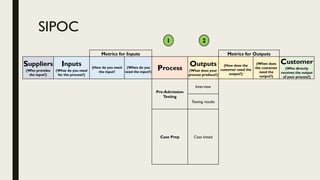

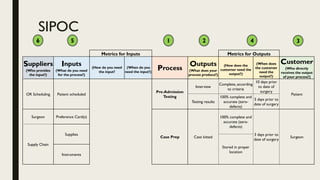

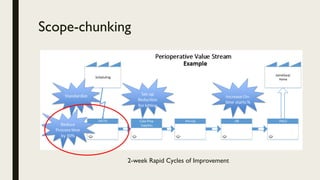

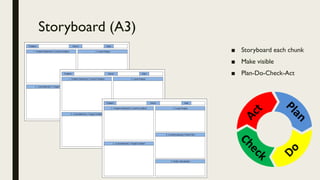

The document outlines a webinar focused on leveraging lean principles for long-term success in organizations under short-term pressures, featuring insights from Mark Graban and Warren Stokes. Key learnings include the importance of engaging frontline employees, simplifying lean processes, and fostering trust for continuous improvement. The presentation emphasizes effective communication, understanding key business drivers, and using visual tools to support incremental improvements in operations.