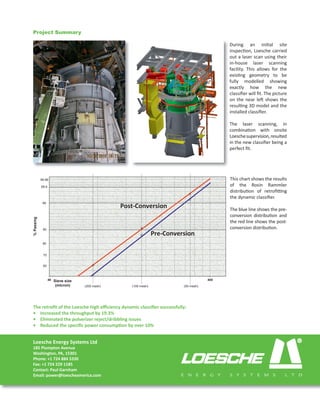

Loesche Energy Systems Ltd was contracted to retrofit a high efficiency dynamic classifier to a coal-fired power station in Kentucky to improve pulverizer performance. The original static classifiers were limiting raw coal throughput to 87,000lb/hr. The Loesche dynamic classifier installation increased throughput by 19.3% while maintaining fineness levels. It also reduced the pulverizer's specific power consumption by over 10%. The retrofit successfully improved the pulverizer's stability and throughput.