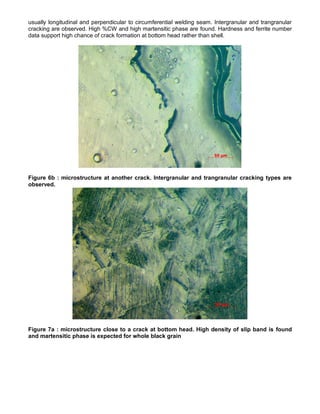

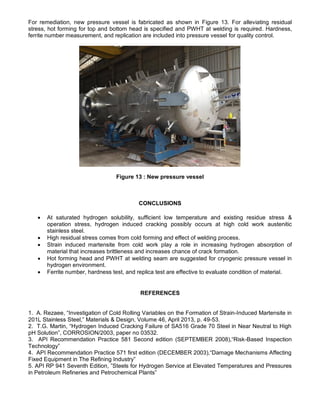

The document discusses an investigation into hydrogen induced cracking that occurred in a cryogenic pressure vessel made of high cold work austenitic stainless steel. Straight cracks initiated internally at the bottom head near welds and grew outward, causing leaks during startup. The investigation found the bottom head experienced higher residual stress and martensite content due to cold forming. During startup, hydrogen absorption reached saturation as temperature decreased, reducing toughness and increasing cracking. To prevent future issues, hot forming and post-weld heat treatment were recommended to reduce residual stress, and material testing to evaluate hydrogen cracking susceptibility.