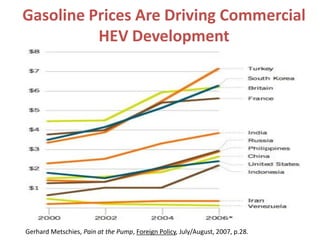

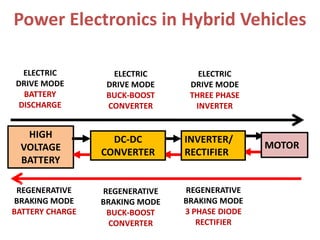

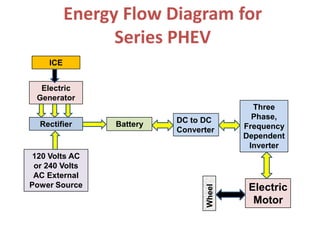

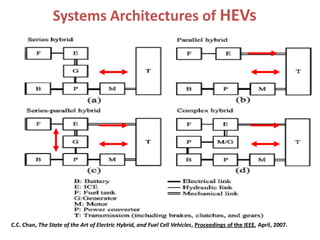

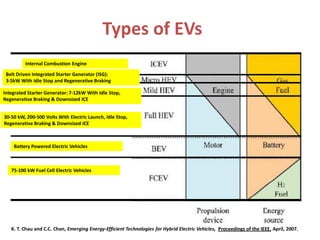

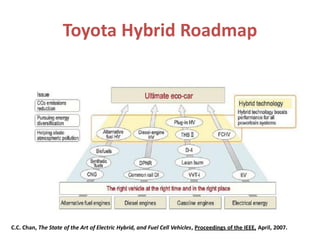

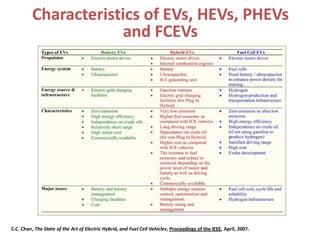

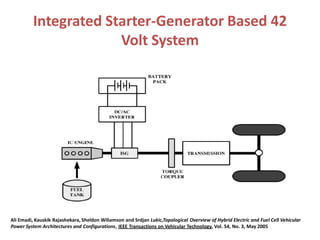

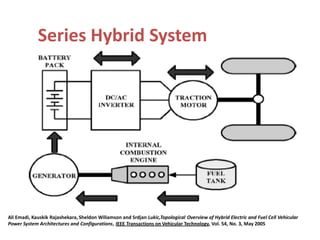

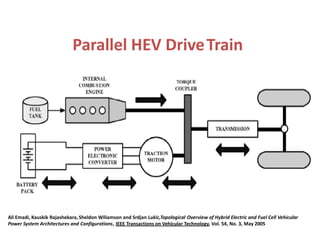

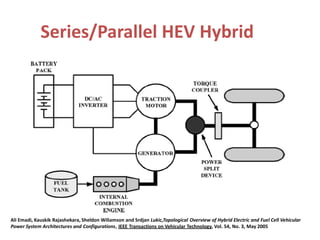

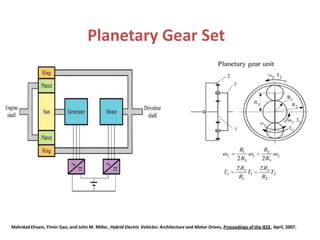

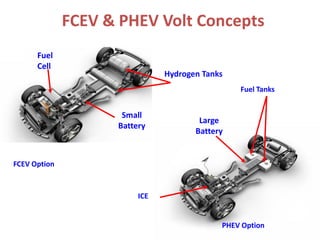

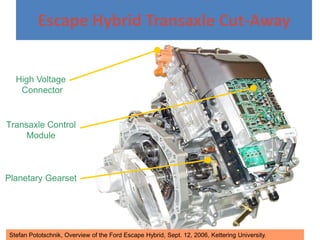

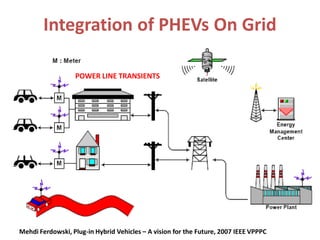

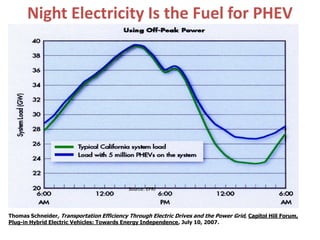

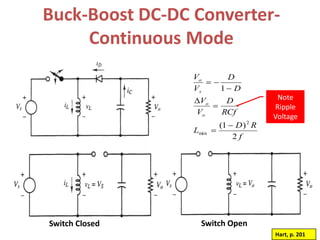

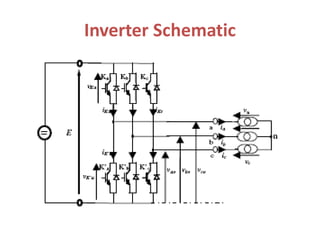

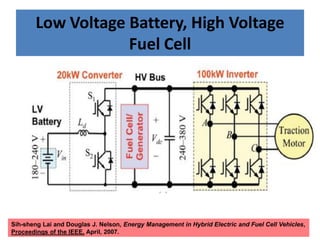

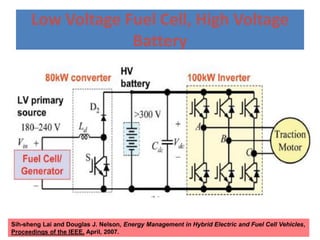

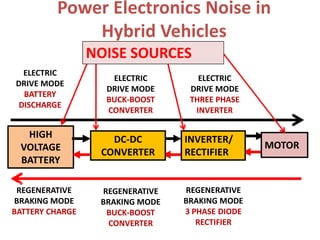

This document provides an overview of hybrid electric vehicles, including different types like HEVs, PHEVs, and FCEVs. It discusses key topics like the development of HEV technologies being driven by rising gas prices and fuel efficiency standards. The document also examines power electronics components in HEVs like batteries, motors, inverters, and converters, as well as different vehicle architectures and how energy flows within series and parallel systems. Manufacturers' HEV development roadmaps are presented along with the characteristics of different electric vehicle technologies.

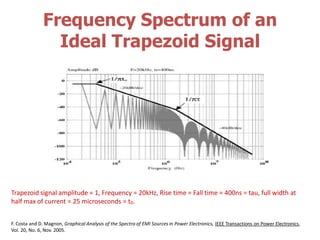

![Noise Spectrum Due to IGBT or

MOSFET Switching in Power

Electronics

''

T

A

]

2

'

2

'

][

2

)

2

(

[

2

T

n

T

n

Sin

T

n

T

n

Sin

T

A

Cn](https://image.slidesharecdn.com/drgoverpresentationsaeapril20-180425152230/85/Hibrido-Toyota-53-320.jpg)