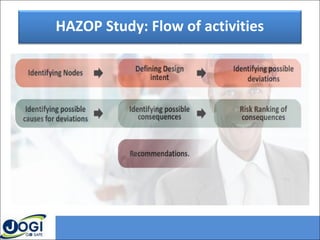

HAZOP is a technique used in process industries to identify hazards and risks. It works by analyzing how a process could deviate from its design intent, identifying potential causes and consequences. The goal is to evaluate safety measures and provide recommendations to minimize risks of incidents like fires, explosions or toxic releases. An effective HAZOP study requires a balanced multidisciplinary team to thoroughly examine the process and identify any gaps or weaknesses in safety systems. Common pitfalls include unclear objectives, imbalanced teams, overly complex documentation and sessions that are too long and lose participant interest.