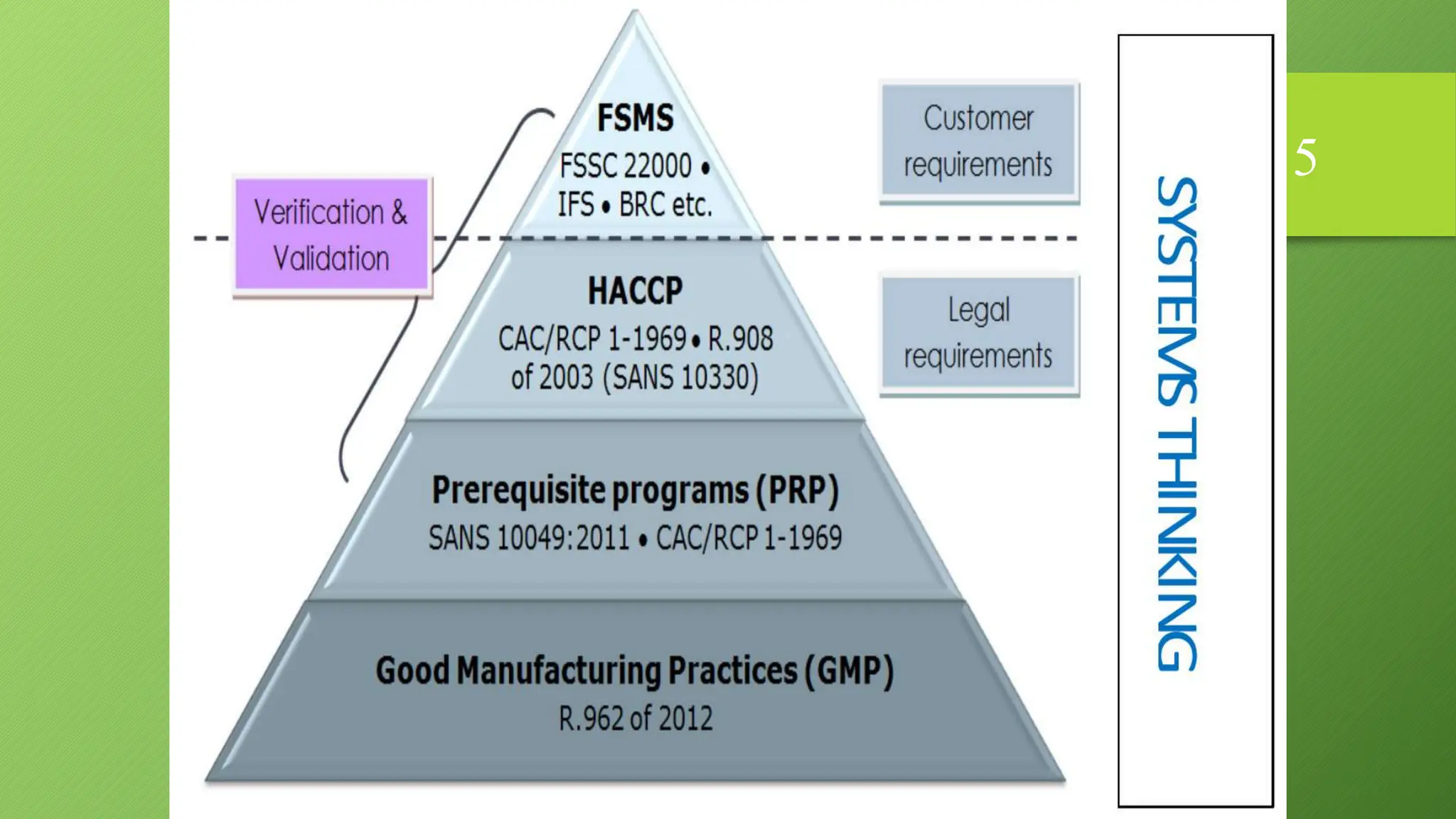

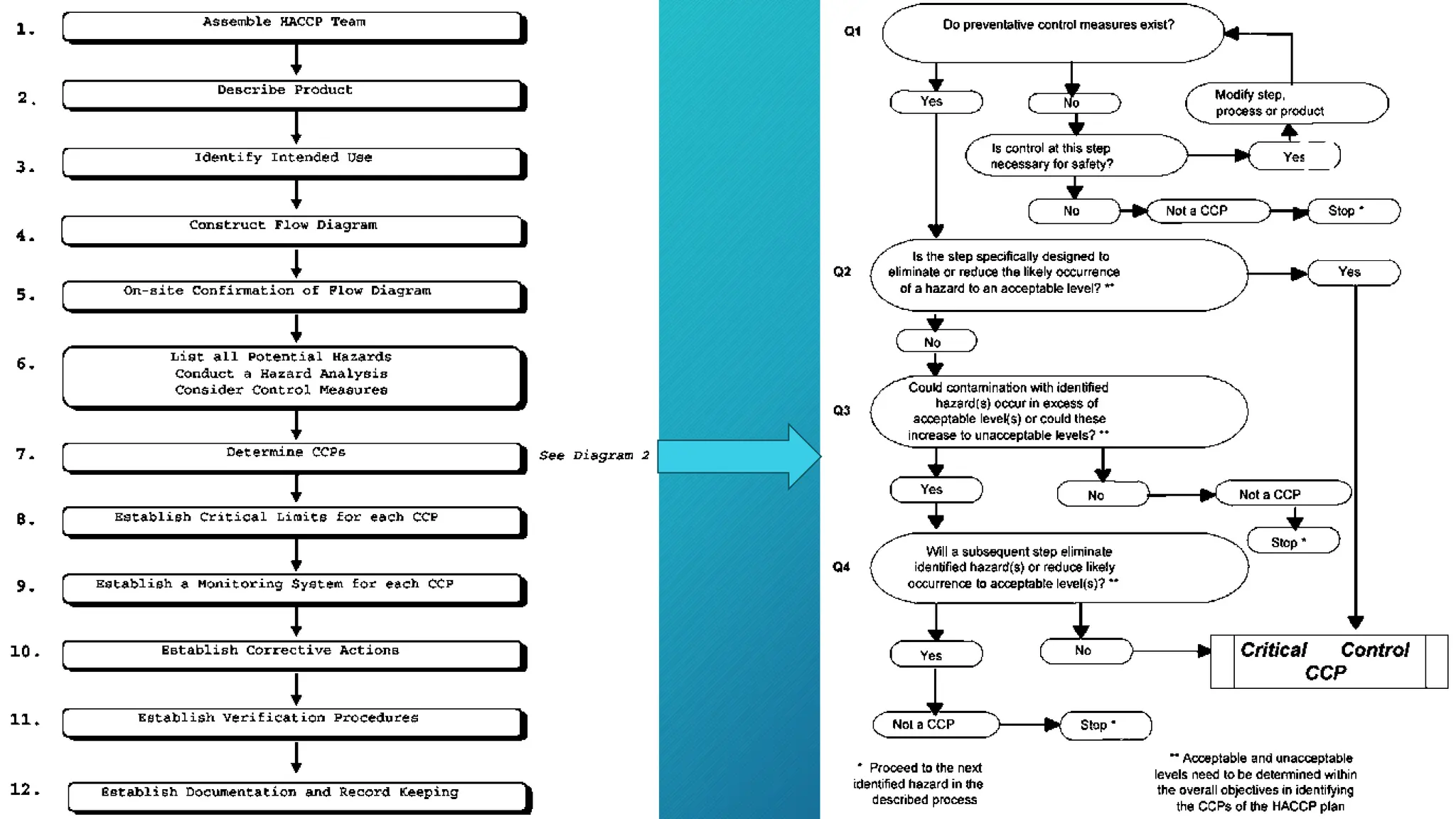

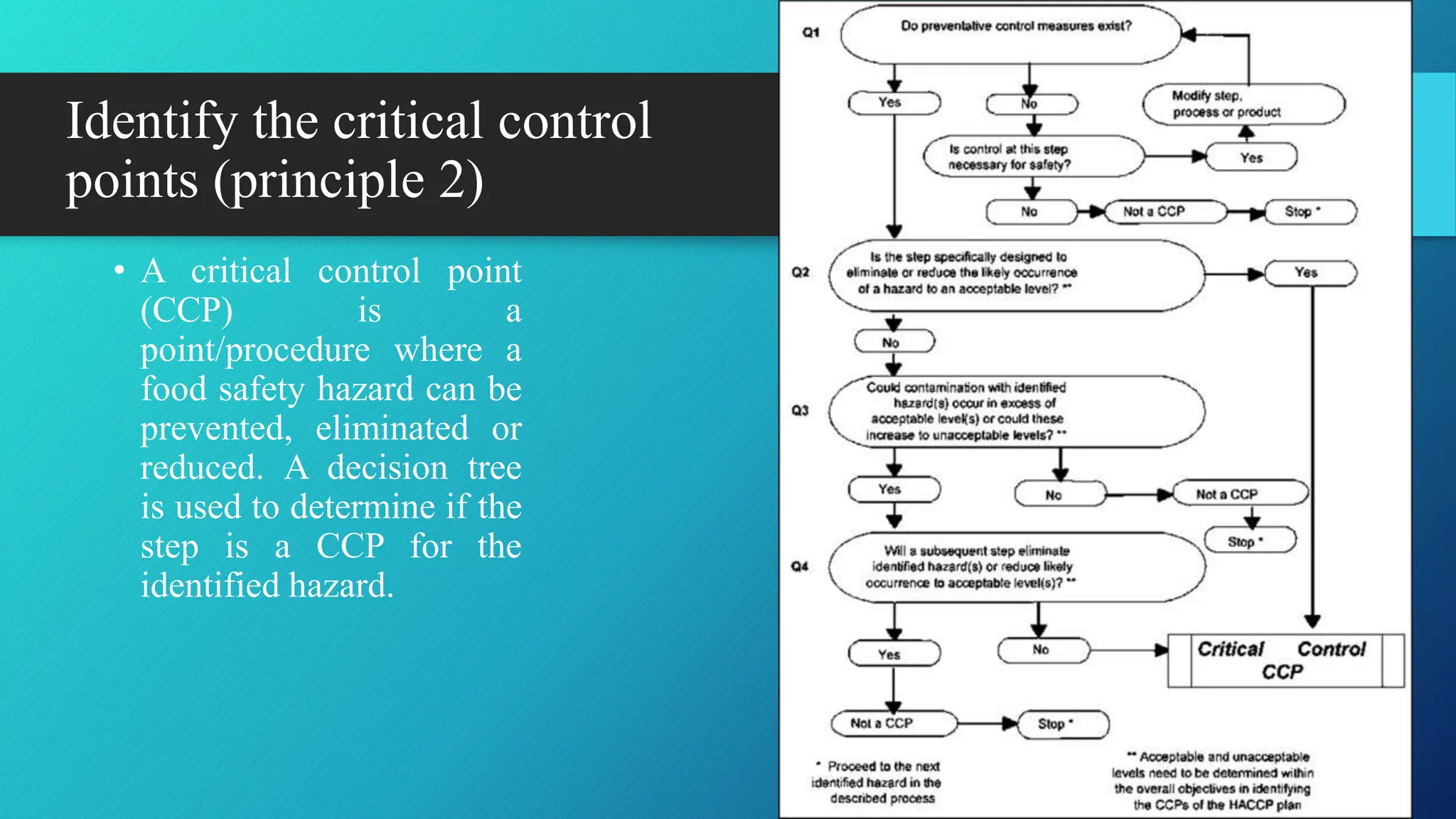

HACCP (Hazard Analysis and Critical Control Points) is an international food safety system established in the 1960s to identify and control hazards in food production processes. It focuses on preventing hazards rather than relying solely on product testing, and its principles have been adopted in various food regulatory frameworks worldwide, including the USA and India. The HACCP system involves a multidisciplinary team conducting risk assessments and establishing critical control points to ensure food safety.